KVE Composites installs first commercial Mobile Induction Welding Cell (MIWC) at Daher

Flexible welding cell developed for coupon welding to facilitate process qualification of KVE INDUCT welding technology for thermoplastic composites.

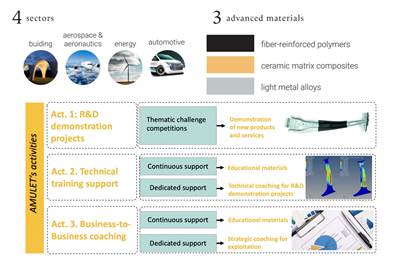

Read MoreAMULET project aims to create new value chains for fiber-reinforced polymers and CMCs

R&D demonstration projects targeting current challenges in auto, aero, energy and building will be developed to reach TRL7 with the goal of accelerating industrial use of advanced lightweight materials.

Read MoreLeveraging motorsports composites for next-gen rotorcraft

FastCan consortium integrates hollow, solid and cored CFRP into single-cure, single-piece canopy for reduced weight and cost.

WatchCosiMo: Smart thermoplastic RTM process demonstrated for battery box cover challenge simulator

Project uses network of DEA, temperature/pressure and ultrasonic sensors plus digital simulation and AI modeling to monitor and optimize injection of caprolactam into complex glass fiber preform and in-situ polymerization of PA6.

WatchXlynX Materials releases new polymer molecular glue: BondLynx

"Hyper glue" adhesive forges new bonds at the molecular level to permanently adhere difficult-to-bond polymers.

Read MoreDLR Institute of Structures and Design increases maturity of thermoplastic composite fuselage structures

Project with Airbus demonstrates OOA co-consolidated stringer-stiffened skin with resistance welded frame and cleats.

Read MoreHydrogen is poised to fuel composites growth, Part 1

Applications abound for composite tanks to store compressed H2 gas, but challenges exist in cost, size, efficiency and limited carbon fiber capacity.

Read MoreArtificial intelligence optimizes CNC milling of carbon fiber-reinforced composites

The Augsburg AI Production Network — DLR Center for Lightweight Production Technology (ZLP), Fraunhofer IGCV and University of Augsburg — use ultrasonic sensors to correlate sound to quality in composites machining.

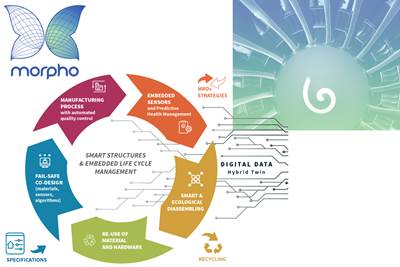

Read MoreDeveloping next-gen, smart engine composite fan blades

EU-funded MORPHO project will use embedded sensors, data-driven hybrid twins and machine learning to increase RTM yield, improve damage-tolerant design, achieve SHM and 100% recycling.

Read MoreCevotec's MAI ACoSaLUS project aims for full automation of composite sandwich structure production

Cevotec works with GKN, TU Munich, SGL Carbon and Augsburg University with an aim to fully automate layup of sandwich parts using FPP, achieve 7-10 times improvement in layup speed.

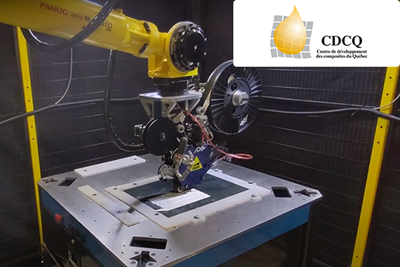

Read MoreQuebec composites development center installs AFP capability

Robotic cell by Effman, Fanuc and Addcomposites enables automation of complex composite layups with tailored fiber orientation for small and medium enterprises (SMEs).

Read MoreIljin Hysolus, Korea's leading composite tank producer for hydrogen storage, sets IPO for Sept. 3

Demand for hydrogen tanks is projected to support sustained growth, according to the company.

Read More