MAE Museum dedicated to and built largely from new and recycled carbon fiber

Museum showcases the advancements in carbon fiber development where visitors can observe transformation process of acrylic fiber into carbon fiber.

Read MoreClean Sky 2 FRAMES project advances heating simulation of thermoplastic composite AFP with xenon flashlamp

Heraeus Noblelight and Compositadour develop heating simulation to optimize process temperatures during automated fiber placement of composite aerostructures.

Read MoreBroetje-Automation delivers EcoPositioners for automated built-in stress-compliant joining in aircraft fuselages

Modularized and highly precise positioning system increases assembly accuracy and speed, enables digitization of CFRP aircraft components assembly for factory of the future.

Read MoreHanwha Solutions acquires Cimarron Composites, aims to be global leader in high-pressure tanks by 2030

Hanwha Cimarron LLC will build new $130 million production facility in Alabama to produce large-scale tanks for hydrogen transport, filling stations and support expansion into tanks for UAM, drones, launch vehicle rockets, defense, rail, cargo ships and more.

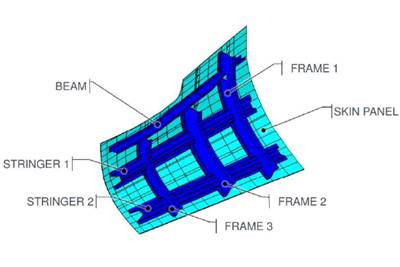

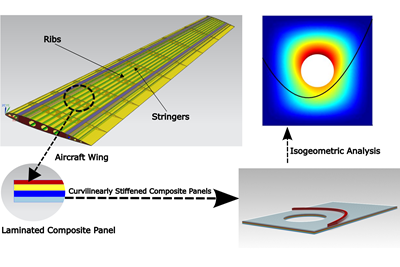

WatchVirginia Tech researchers develop IGA for more efficient modeling of skin-stringer composites with complex cutouts

Isogeometric analysis offers higher rates of convergence and accuracy versus standard FE methods, will be offered as opensource code on GitHub.

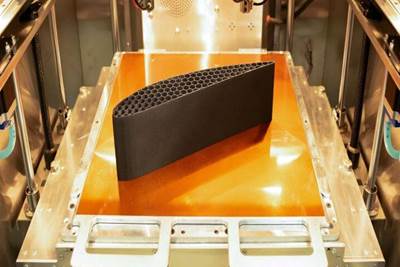

Read MoreAON3D debuts AON M2+ printer to fabricate high performance end-use parts

Printer aimed to exceed aluminum parts using chopped carbon fiber and high-performance polymers (e.g., PEEK, PEKK, ULTEM) via widely available, off-the-shelf filaments.

Read MoreFirefly to become the premier supplier of spaceflight composite components for New Space industry

Negotiating to supply components, such as composite overwrapped pressure vessels (COPV), to external customers, as part of full product line and new space marketplace.

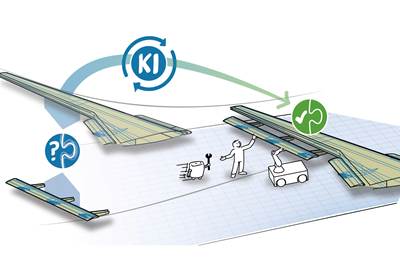

Read MoreDLR develops concept for final assembly line with artificial intelligence

High-rate production enabled by pre-selection of assembly-ready components, without manual compensation measures, based on neural network training.

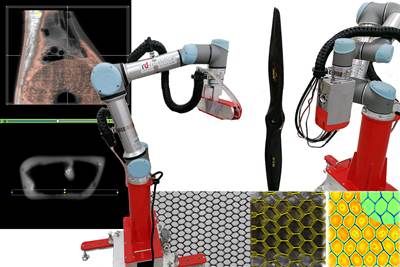

Read MoreRobotic computed tomography – removing NDT barriers for composites

Radalytica uses collaborative robots, ultra-sensitive X-ray photon detectors and the ability to combine CT with ultrasound, surface profiling and other inspection methods to optimize composites part quality, production and reduce cost.

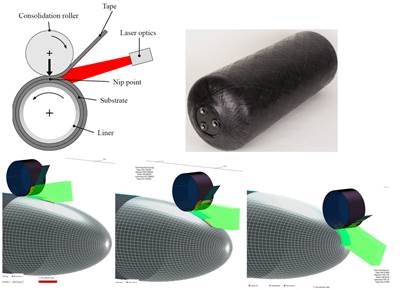

WatchOTOMcomposite develops software for Composites 4.0 production using laser-assisted tape placement and winding

Optical thermal optimization model (OTOM) software enables inline monitoring and control for improved part quality and reduced production time and cost of in-situ consolidated thermoplastic composites and Type IV pressure vessels.

WatchGE, LM, NREL complete successful automated blade finishing trials

Pilot project started in 2020 leverages knowledge of advanced composites processing together with sensing, robotics and automation for low-cost solutions to boost throughput by 30%.

Read MoreUniversal Hydrogen signs deals with three airlines for hydrogen propulsion retrofits

Carbon fiber storage tanks will reduce the Dash-8’s cabin space from 56 seats to 40 seats, but enable emissions-free travel up to approximately 460 miles.

Read More