Hexagon Purus and CIMC Enric for construction of joint production facility and New Energy R&D management center

Investment agreements establish new facilities in China, aiming toward increased production capacity of hydrogen storage vessels.

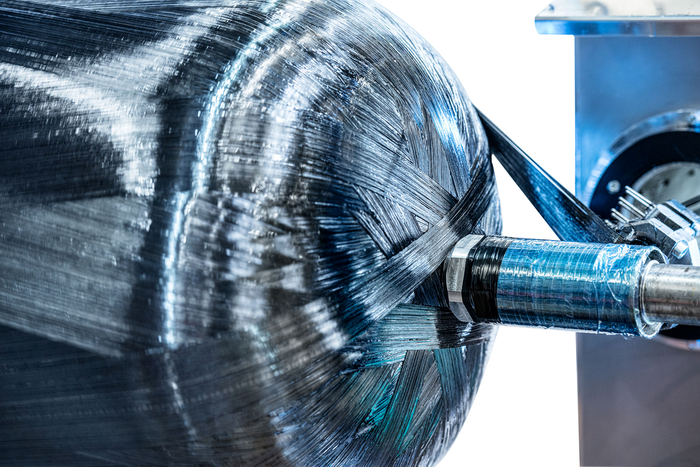

Photo Credit: CIMC Enric

Hexagon Purus (Ålesund, Norway), a division of Hexagon Composites (Ålesund) and CIMC Enric (Shenzhen, China) have signed investment agreements to establish a joint production facility in Shijiazhuang, Hebei province, China as well as the CIMC-Hexagon New Energy Technologies management office and engineering hub. In addition, the Shijiazhuang and Beijing Daxing governments have made a strong commitment to support the development of the CIMC-Hexagon business in their regions through 2030.

- Construction of the new composite cylinder and systems manufacturing facility in Shijiazhuang is expected to commence in Q2 2022, and the facility will house Type 3 and Type 4 hydrogen cylinder production and systems assembly capacity.

- Technologies management office and engineering hub will be located in Beijing Daxing District International Hydrogen Development Zone, one of China’s leading areas for advancement of hydrogen technologies and application scenarios.

- The facilities will set a benchmark for highly automated production of composite hydrogen pressure vessels from 350 to 700 bar intended for the Chinese and Southeast Asian markets including storage systems for on-road vehicles, rail and maritime applications.

- The new facility is expected to create several hundred jobs in Shijiazhuang and Beijing and will also support business for regional suppliers.

Hexagon Purus and CIMC Enric previously signed joint venture agreements in 2021 regarding cylinder and systems production for Fuel Cell Electric Vehicles (FCEVs) and hydrogen distribution in China and Southeast Asia, expected to become the world’s largest zero emission hydrogen vehicle and distribution markets.

“As part of our global expansion program, CIMC-Hexagon will become the hub for high quality and highly automated manufacturing of high-pressure composite hydrogen storage cylinders and systems for China and Southeast Asia,” says Morten Holum, CEO of Hexagon Purus. “We are looking forward to making a contribution to the local transportation sector, addressing the substantial growth potential for hydrogen technology in the region as a reliable supplier of advanced technology.”

Leo Yang, CEO of CIMC ENRIC adds, “CIMC ENRIC, through CIMC-Hexagon, and the broad spectrum of hydrogen related products and services, offers a unique portfolio of total solutions to vehicle fleet owners, railway and maritime operators. Shijiazhuang has been CIMC Enric’s manufacturing base for over two decades. We are confident that this environment offers our Joint Venture with Hexagon Purus a modern and industrialized environment that can deliver a competitive and highly skilled workforce, as well as strong support from the local government.”

Powerful alliance

CIMC Enric is a leading global supplier of cryogenic and compressed gas storage and transportation solutions and manufacturer of clean energy equipment. It is listed on the Stock Exchange of Hong Kong. Hexagon Purus, a global leader in Type 4 hydrogen cylinder and battery electric systems technology, is listed on the Oslo Stock Exchange.

This cooperation is a highly compelling partnership: Hexagon Purus’ world class Type 4 hydrogen cylinder and systems technologies and design with over 20 years of heritage and safety track record – and CIMC Enric’s extensive expertise in gas system development tailored to the Chinese market and its long-standing relationships with large Chinese vehicle manufacturers (OEMs) and gas distribution companies.

The joint venture will serve the fast-growing demand of the Chinese market for safe, lightweight and cost-efficient compressed hydrogen storage solutions. Relevant industrial standards for Type 4 cylinders are currently being established by the Chinese government. The joint venture will also support the transition to zero emission mobility solutions in Southeast Asia.

World’s largest auto market

China, the world's largest auto market with over 28 million vehicles sold annually, has set its sights on creating a world-leading market for FCEVs within two decades. As forecasted by industry experts based on Chinese policymakers’ planning, the market will grow from more than 7,000 FCEVs by end of 2020, to 1.3 million FECVs by 2035. It is also expected that hydrogen will account for approximately 10% of primary energy consumption in China by 2050.

The initial focus of the Chinese hydrogen strategy is on fuel cell electric buses and commercial vehicles. This will improve public awareness and showcase the safety of hydrogen. The Association of Southeast Asian Nations (ASEAN) announced its collective ambition to achieve 23% renewable energy integration into its energy system by 2025, and even more by 2035.

The shift to zero emission vehicles is driven by the desire to improve air quality and reduce CO2 emissions, as well as to increase energy independence by utilizing large amounts of hydrogen already available in China. In addition, hydrogen provides cost-efficient storage for surplus renewable energy from wind and solar.

Related Content

Carbon fiber, bionic design achieve peak performance in race-ready production vehicle

Porsche worked with Action Composites to design and manufacture an innovative carbon fiber safety cage option to lightweight one of its series race vehicles, built in a one-shot compression molding process.

Read MoreThe potential for thermoplastic composite nacelles

Collins Aerospace draws on global team, decades of experience to demonstrate large, curved AFP and welded structures for the next generation of aircraft.

Read MoreBio-based acrylonitrile for carbon fiber manufacture

The quest for a sustainable source of acrylonitrile for carbon fiber manufacture has made the leap from the lab to the market.

Read MoreComposites manufacturing for general aviation aircraft

General aviation, certified and experimental, has increasingly embraced composites over the decades, a path further driven by leveraged innovation in materials and processes and the evolving AAM market.

Read MoreRead Next

All-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read MoreDeveloping bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read MoreVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read More