DOMMINIO virtual workshop to explore multifunctional and intelligent composite airframe parts

Nov. 30, 2021 event for H2020 project will review latest advances in thermoplastic composites, additive manufacturing and digital manufacturing.

Read MoreVABO Composites launches new company in Italy

VABO Italia Composites Srl will be based in La Spezia and act as sister to the Netherlands HQ, including custom composites projects and new products.

Read MoreEmbraer unveils four Energia concept aircraft for net-zero aviation by 2050

Aircraft being developed span 9 to 50 seats and electric, hydrogen fuel cell, dual-fuel gas turbine and hybrid-electric propulsion.

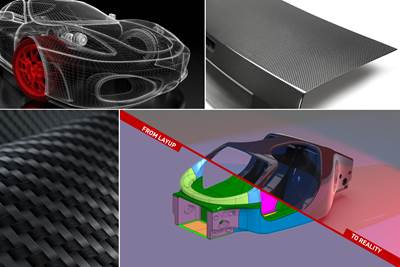

WatchCreating stronger composites through nature-inspired, Helicoid designs

Helicoid Industries claims 50% increased toughness, impact strength and reduced material, weight and cost versus quasi-isotropic “fail-safe” designs.

Read MoreBoeing ecoDemonstrator tests recycled carbon fiber sidewalls, acoustic upgrades for aeroengines and more

Eight aircraft since 2010 have demonstrated new technologies to reduce noise, improve efficiency and minimize aviation’s environmental footprint, with potential impacts for future wings, interiors, engine nacelles and vertical tail design.

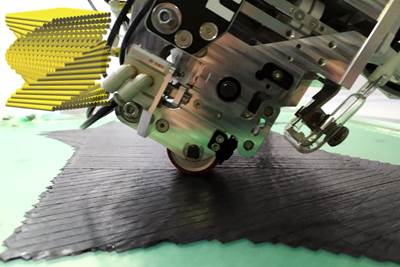

WatchSAM|XL develops closed-loop manufacturing for composites

Collaborative R&D center at TU Delft develops sensor- and robot-based automation for Composites 4.0 manufacturing, including STUNNING project for welded assembly of a thermoplastic composite fuselage demonstrator.

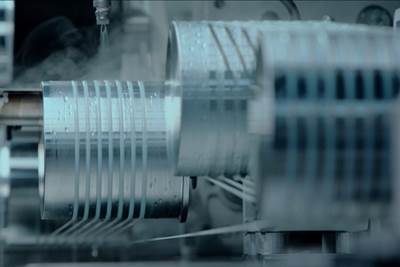

WatchMikrosam celebrates commissioning of world's largest production line for CNG and hydrogen tanks

Turnkey project integrates four filament winding machines, two large ovens and multiple robotic lines and buffering stations to produce 60,000 tanks per year.

WatchHydrogen is poised to fuel composites growth, Part 2

Potential for Type IV composite tanks in H2 refueling stations and distribution, plus targeted cost reductions and emerging technologies for tank recertification and monitoring.

Read MoreThe Native Lab offers hands-on and online courses in composites

Training arm of engineering consultancy Managing Composites seeks to “make people native in composites.”

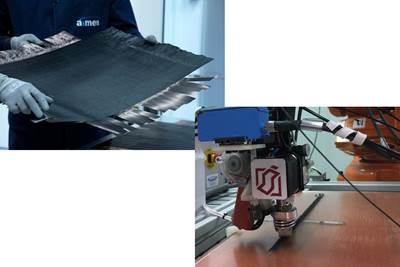

Read MoreLeonardo invests for the future, establishes pilot carbon fiber plant in Italy in collaboration with MAE

Part of government-supported project to innovate composites, pilot line will be operational in 2022 and enable testing of new precursors and process variations.

Read MoreRVmagnetics joins European Technology Chamber (EUTEC)

Slovak-based R&D and sensor technology company pursues opportunity to promote industrial innovation in a more institutionalized manner.

Read MoreAirbus X-Wing will test flapping wing tips, multifunctional trailing edges for future aircraft

Demonstrator will test 30%-scale version of 52-meter composite wing with electrically-powered actuating hinged wing tip for improved efficiency and decarbonization in flight.

Watch