Deutsche Aircraft and H2FLY join forces to explore hydrogen powered flight

First flight of Dornier 328 demonstrator with fuel cell planned for 2025 to display potential for climate-neutral regional flights.

WatchUT Austin installs Addcomposites AFP-XS with laser for in-situ consolidation of thermoplastic composites

Modular, compact and versatile AFP system to help University of Texas explore thermoplastic composites technologies.

Read MoreLockheed Martin Australia and Omni Tanker develop new composite tanks for cryogenic fuels

Partnership aims to commercialize Type IV and V tanks using patented OmniBIND technology for Lockheed Martin and NASA applications.

Read MoreVolocopter secures EASA production approval, acquires DG Flugzeugbau’s manufacturing operations

UAM pioneer will integrate renowned composite glider manufacturer and 10-year partner while sailplane ops will continue as DG Aviation

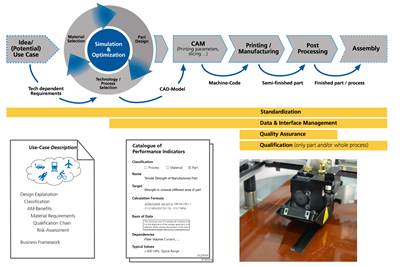

Read MoreEmpowerAX strengthens accessibility to continuous fiber 3D printing

Platform joins technology users and providers to work on standards, tests and frameworks for faster, lower-cost evaluation and implementation of additive extrusion technologies for industrial parts.

Read MoreThe democratization of composites is reconfiguring supply chains

New robotic and digital technologies are enabling advanced in-house capabilities for small companies and innovative suppliers willing to embrace the move toward more affordable, sustainable composites.

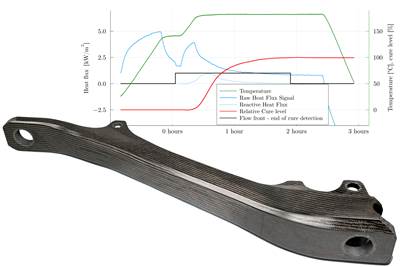

Read MoreSpeeding RTM with heat-flux sensors

Clean Sky 2 INNOTOOL 4.0 project advances cure monitoring for larger and less costly lightweight landing gear made using composites.

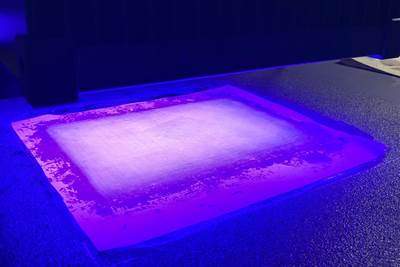

Read MoreEasy-to-use kits enable infield repair of composite structures

Portable kit enables patch repairs using UV-cure glass fiber/vinyl ester or room-temp stored carbon fiber/epoxy prepregs and battery-powered curing equipment.

Read MoreVictrex launches LMPAEK polymer grade for 3D printing

Victrex AM 200 improve melt extrusion by filament fusion (FF), direct granule extrusion, and laser sintering processes and enhances z-strength and interlaminar strength.

Read MoreCEAD launches new E50 Robot Extruder for larger 3D-printed composites

New option offers higher material output (e.g., 84 kg/hr) and thermoplastic melt temperatures up to 400°C.

Read MoreRobotic injection molding for functionalized composites

Anybrid enables compact, flexible hybrid injection molding/overmolding for smaller series and larger components.

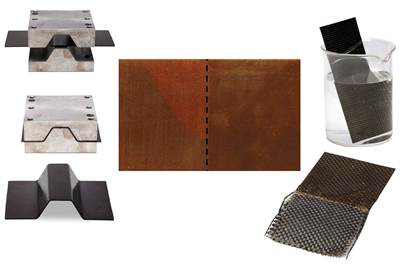

WatchReprocessable, repairable and recyclable epoxy resins for composites

CIDETEC matures 3R resins for aerospace applications via AIRPOXY program.

Watch