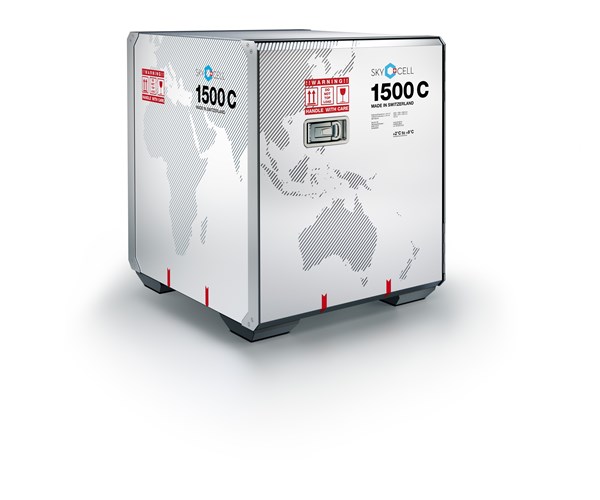

Multi-material shipping container for pharmaceuticals

This past week, CW was made aware of a new, high-tech and multi-material unit load device (ULD) shipping container solution from an innovative container company called Smart Containers Group (Zurich, Switzerland).

Smart Containers Group’s SkyCell multi-material shipping container

Containerization, or massing smaller pieces of cargo together in a single, larger container, was first practiced for shipping of coal in 17th Century England. The idea has evolved since into the now-ubiquitous stackable intermodal containers seen on container ships, trains and trucks. Likewise, the commercial aircraft industry developed lighter-weight container versions called Unit Load Devices, or ULDs, to containerize cargo shipments on planes. Several efforts have been reported in CW of composites-intensive ULDs (for instance, here: https://www.compositesworld.com/news/tencate-advanced-armor-usa-will-fabricate-composite-cargo-containers-for-air-cargo-containers-providing-material-and-assembly-). This past week, CW was made aware of a new, high-tech and multi-material ULD solution from an innovative container company called Smart Containers Group (Zurich, Switzerland).

Smart Containers Group is working with the pharmaceutical industry, where safe, temperature-controlled shipping of sensitive goods is vital. Smart Containers Group CTO and co-founder Nico Ros spoke to me about what goes into this high-tech shipping box.

In shipping pharma products, he explains, it is vitally important that the temperature of the product be constant, and that fragile contents withstand the shocks of handling. The key attributes of the SkyCell container had to be, therefore, the ability to absorb double-digit G forces, and have a highly-efficient insulation layer, all while keeping overall weight less than competing metallic ULD boxes. “We combine composite materials with aluminum in such a way so that the container can withstand substantial force via damping, to protect fragile contents. We liken it to a coconut, which has a relatively soft fiber skin but a hard core inside,” says Ros. The group wanted a skin material with some give that would not dent, like existing all-aluminum ULDs. They chose commingled ABS plastic fiber/woven textile (similar to the CURV self-reinforced composite material from Propex, Chattanooga, TN, US), held in place with aluminum extrusions at the edges and corners. Ros says, “It’s like a stretched canvas for an oil painting — the frame is rigid, and the ‘canvas’ has some flexibility. It’s a stable, lightweight solution.”

The reinforced fabric is backed by a highly-engineered core, which originated during a European research project to find ways to recycle and reuse non-food grade PET (polyethylene terephthalate) discards. His group developed a patented process to co-extrude nano-treated recycled PET granulate between two aluminum coatings, stamped with a raised honeycomb pattern. The proprietary aluminum surfaces, which form the upper and lower skins of the core, have a thickness of ~20nm, and the total core thickness is approximately 0.1 mm thick. Explains Ros, “This ultra-thin core design gives us metal-like properties to reflect heat but also gives us plastic-like properties for lower temperature conductivity.” The core surrounds an inner aluminum box within which the pallet is placed. Ethylene propylene diene monomer (EPDM) synthetic rubber feet support the box; the EPDM was selected for its acid resistance. Total external ULD dimensions for the 1500C ULD are 153 cm long by 132 cm wide by 160 cm high, to meet aircraft cargo container size; the inside dimensions are consistent with US standard pallet size. Maximum load rating is 1000 kg. On-board cloud-connected IoT sensors, based on blockchain technology, allow continuous monitoring. The company says the combined elements of the container, composite and metallic, are protected by 96 patents.

According to Smart Containers Group, it is the fourth largest supplier of containers to the pharmaceutical industry, and 12 major pharma firms have already validated the container for their products. This is due to the container’s performance at maintaining desired low temperatures, termed the “cold chain,” with a very low failure rate of 0.1%, compared to the overall industry average failure rate of 6 to 8%, says Ros: “For our customers, the actual production cost is not the point, it’s the logistics cost that is low because of the high performance and low failure rate of the container. Plus, the industry pools containers and they are reused many times. It is a niche market, but it’s a demanding market, and it will allow us to springboard into other applications, including perishable food shipping.”

To learn more about Smart Containers Group and their philosophy, visit the web site (https://smartcontainers.ch/) and watch this video of CEO and co-founder Richard Ettl introducing the SkyCell container at the Crypto Finance Conference earlier this year:

Related Content

Thermoplastic composites welding: Process control, certification, crack arresters and surface prep

More widespread use of welded composite structures within a decade? Yes, but further developments are needed.

Read MoreDemonstrating composite LH2 tanks for commercial aircraft

Toray Advanced Composites and NLR discuss the Netherlands consortium and its 4-year project to build demonstrator liquid hydrogen tanks, focusing on thermoset and thermoplastic composites.

Read MoreProtecting EV motors more efficiently

Motors for electric vehicles are expected to benefit from Trelleborg’s thermoplastic composite rotor sleeve design, which advances materials and processes to produce a lightweight, energy-efficient component.

Read MoreThe potential for thermoplastic composite nacelles

Collins Aerospace draws on global team, decades of experience to demonstrate large, curved AFP and welded structures for the next generation of aircraft.

Read MoreRead Next

The next-generation single-aisle: Implications for the composites industry

While the world continues to wait for new single-aisle program announcements from Airbus and Boeing, it’s clear composites will play a role in their fabrication. But in what ways, and what capacity?

Read MorePlant tour: Teijin Carbon America Inc., Greenwood, S.C., U.S.

In 2018, Teijin broke ground on a facility that is reportedly the largest capacity carbon fiber line currently in existence. The line has been fully functional for nearly two years and has plenty of room for expansion.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read More