Composite Kape skateboard delivers durability, pop

Collaborative effort between KraussMaffei and entrepreneur Peter Karacsonyi led to the Vanguard, an in-situ polymerized board comprising fiberglass sandwich composites with a recyclable polyamide.

Share

It needs “pop” to take off. The new skateboard from Kape retains this feature much longer than conventional wooden decks. Source | Hannes Mautner

After more than 10 years of development, and with the help of KraussMaffei’s (Parsdorf, Germany) production equipment, Peter Karacsonyi, founder and CEO of Kape Skateboards, has developed a board option made of glass fibers reinforced with recycled polyamide, a considerably more sustainable option than previous wooden models. The first small series, the “Vanguard” deck, was launched at the end of August and sold out within 5 hours.

According to Karacsonyi, professional skateboarders who ride laminated wooden skateboards have to change them frequently, as the boards — called “decks” — splinter easily and lose their tension due to microcracks. This then requires more energy to “lift off” during tricks. For Karacsonyi, an enthusiastic skater and skateboard builder since childhood, it was clear that something had to change. More “pop,” better performance, more sustainability and simpler production processes were his goals.

Karacsonyi has been tinkering since 2014. He initially began with a pressed multilayer system made from wood veneers and carbon fiber. He was able to convince two investors with the idea on the TV show “Höhle der Löwen” and sold several thousand boards.

However, this was not enough for Karacsonyi. When the technology could no longer be improved, he came up with the idea of casting skateboards instead of pressing them, using organosheets made of fiberglass and adding a ribbed structure via injection molding. It was already clear at this point that the material used should be a thermoplastic, because the recycling possibilities are improved. The concept was developed and patented, but ultimately not implemented because the cycle times would have been too long due to the high wall thickness and the complexity of the process.

Karacsonyi next turned his attention to in-situ polymerization. In this process, the plastic is not processed in granulate form, but its basic materials only react with each other in the mold itself. For the polyamide, this is caprolactam plus activator and catalyst. Caprolactam is as liquid as water. The process, therefore, promised particularly good penetration of the glass fibers. In contrast to injection molding, it would also make it possible to produce a sandwich composite in a one-shot process. A foam body developed in-house (also made of polyamide) was to serve as a lightweight core material. After a manual test had shown that his concept worked, Karacsonyi set out in search of industrial partners to manufacture the deck — which ended in frustration. Suppliers in Austria and Hungary did not deliver the desired quality and the collaboration proved to be less than cooperative.

Peter Karacsonyi with his innovative Vanguard composite skateboard, which is produced using KraussMaffei manufacturing equipment. Source | Leo Rosas

Karacsonyi, therefore, went “all in” and decided to take the production of the Vanguard into his own hands. This meant looking for a suitable production system consisting of a mold carrier, mold, dosing machine and automation. In order to be able to realize his vision financially, he acquired research funding and brought investors on board. Since 2019, the focus has been exclusively on the composite deck; production of the previous boards has been discontinued.

The chemistry with the KraussMaffei team in Georgsmarienhütte/Harderberg was right from the outset, enabling them to overcome challenges together. In addition to mechanical flexibility — for process-specific reasons, the mold carrier had to be as flexible as possible — KraussMaffei’s technology enabled them to surpass all of the unusually high mold temperature that caused headaches.

Normally, 40-60°C prevail here, but 140-160°C were needed for the skateboard. As a result, many standard components such as cylinders and valves could not be used and had to be replaced with alternatives. In order to keep energy consumption as low as possible and not heat up the entire metal construction, the mold and mold carrier were thermally separated from each other using insulating plates. By using an air cushion, the upper and lower parts can be forcefully sealed together. “The whole thing grew almost organically,” recalls design engineer Florian Jovanovic. The result is a reliable series production process with an optimally coordinated system.

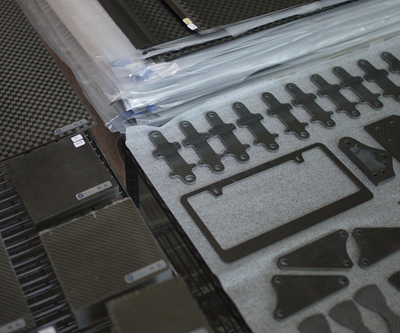

For each board, Karacsonyi’s Kape employees now takes a sandwich made of unidirectional continuous glass fibers and an intermediate foam core and inserts it into the mold. The mold carrier closes, the vacuum is applied and the polyamide components are added. Incidentally, Karacsonyi did not take the easy way out with the caprolactam either. In order to make his board even more sustainable — in addition to extending its service life — he found a supplier for the monomer in Italy that extracts it from fishing nets and industrial waste using chemical recycling.

“Working with Peter on this project was great,” says Giulio Bonazzi chairman and CEO of Aquafil SpA (Arco/Trento, Italy). “Producing the skateboard with Econyl caprolactam was a real challenge, yet unique experience. And what made it even better was the fact, that we shared the same sustainable values with the team — that made the difference.”

After around 6 minutes, the tool opens and the 80 × 21-centimeter Vanguard skateboard can be removed. The only rework required is the removal of a wafer-thin polyamide edge and the 0.7-millimeter-thick sprue, which is done with a knife. The visible structure of the deck characterizes the look, only clear varnish and a screen print are applied.

Those purchasing the Vanguard only have to screw on their trucks and wheels and they’re ready to go, without the worry of splintering or breaking, but with “pop” that lasts and the feel and sound of wood. This has been confirmed by previous test riders, including several Olympic athletes and Kape team rider Levi Löffelberger.

According to the partners, the production of skateboards had remained more or less the same since the 1970s. The composite technology from Karacsonyi/ Kape with equipment from KraussMaffei is now changing that.

Related Content

Plant tour: Albany Engineered Composites, Rochester, N.H., U.S.

Efficient, high-quality, well-controlled composites manufacturing at volume is the mantra for this 3D weaving specialist.

Read MoreNatural fiber composites: Growing to fit sustainability needs

Led by global and industry-wide sustainability goals, commercial interest in flax and hemp fiber-reinforced composites grows into higher-performance, higher-volume applications.

Read MoreCryo-compressed hydrogen, the best solution for storage and refueling stations?

Cryomotive’s CRYOGAS solution claims the highest storage density, lowest refueling cost and widest operating range without H2 losses while using one-fifth the carbon fiber required in compressed gas tanks.

Read MoreThe lessons behind OceanGate

Carbon fiber composites faced much criticism in the wake of the OceanGate submersible accident. CW’s publisher Jeff Sloan explains that it’s not that simple.

Read MoreRead Next

From carbon fiber skateboard maker to contract manufacturer

Elevated Materials makes its mission to deliver reclaimed high-quality aerospace carbon fiber to a variety of industries.

Read MoreThermoplastic composites add light weight, durability to personal transport

The laptop-sized WALKCAR automatic people mover is constructed from Teijin thermoplastic carbon fiber composite materials.

Read MoreKraussMaffei, AIM collaboration achieves HP-RTM carbon fiber wheel rims

KraussMaffei supported, coordinated and delivered compact production equipment tailored to design and process needs for high-quality automotive rims.

Read More