Urban furniture project demonstrates green potential for composite 3D printing and recycled materials

Large-format AM specialist Caracol and partners designed custom, 3D-printed outdoor furniture with glass fiber-reinforced recycled polypropylene, and conducted an LCA to evaluate and improve the process.

Share

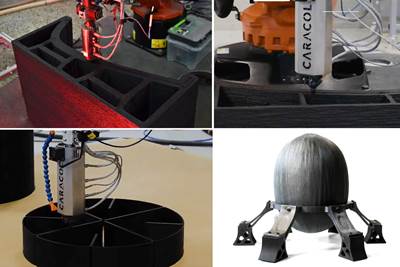

Caracol and its partners used glass fiber-reinforced recycled polypropylene to design and additively manufacture a series of urban furniture pieces, aiming to demonstrate potential for 3D printing and recycled materials as a circular economy solution. Photo Credit: Caracol

The MASAU project, led by large-format additive manufacturing (LFAM) equipment supplier Caracol (Barlassina, Italy), demonstrated and evaluated the sustainability potential for 3D printing composites and recycled materials to contribute to a circular supply chain solution.

In June 2022, the Lombardy region in northern Italy invited local companies to submit applications for funding related to building up the local circular economy supply chain. Caracol and Italian partners including the ComoNExT Innovation Hub (Lomazzo), the Polytechnic University of Milan and Lifecycle Engineering SpA (LCE, Turin) participated with their 1-year project MASAU, which stands for “Manifattura Addittiva Sostenibile per Arredi Urbani” in Italian, or “Sustainable Manufacturing for Urban Furniture.”

For this project, outdoor furniture was chosen as a focus application to demonstrate the technology. Caracol’s application engineering team designed a series of seating pieces and planters that were then manufactured at its facility using the company’s Heron AM system.

The ComoNExT Innovation Hub provided support and coordinated with the city of Lomazzo for placement of the final demonstrator parts in public spaces. LCE conducted a lifecycle assessment (LCA) to provide information on the environmental impact of the process.

The furniture design aimed to provide a positive impact for the environment and within society. The seating was designed into organic shapes for a semicircle setup to foster inclusivity and social interaction, and a series of planters were designed and fitted with solar-powered smart sensors that trigger an automatic irrigation system when needed.

According to Violetta Nespolo, chief marketing and strategy officer at Caracol, one of the first steps of the process was evaluation of materials that would meet the requirements of the Heron AM process and project goals for the lowest environmental impact. The Polytechnic University of Milan helped test materials, including characterization of a variety of recycled materials to ensure needed repeatability, durability and performance.

“We looked for the best local supplier who could provide a good quality material with a high percentage of recycled content,” Nespolo says. Ultimately, the project partners selected a recycled polypropylene made from post-consumer or post-industrial plastic materials, reinforced with 30% chopped glass fiber. The material combination “gives us much better printability as well as resistance for the finished parts, which will have to withstand outdoor environments,” Nespolo says. Partners also selected the material with the highest recycled content while still meeting performance requirements.

Caracol’s Heron AM high accuracy printhead during the printing of one of the MASAU demonstrator pieces. Photo Credit: Caracol

Caracol’s Heron AM was used to fabricate the demonstrator parts. The extrusion-based 3D printer is mounted on a six-axis KUKA (Augsburg, Germany) robotic arm, set up within a climate-controlled cell and operated by Caracol’s in-house, integrated design and manufacturing software. For this project, the company’s highest accuracy print head was used. “As the parts weren’t post-processed, we wanted to achieve good quality right off the machine and use the minimum quantity of material necessary,” Nespolo explains.

Compared to traditional composites manufacturing processes, she adds that Caracol’s process minimizes energy consumption, material use and generated waste, as well as cycle time per part.

To further demonstrate this and provide learnings for further improvement, project partner LCE conducted an LCA after the demonstrators were built, to quantify the current environmental impact of the manufacturing process, based on ISO standard 14040-44. Several key performance indicators (KPI) were evaluated, including carbon emissions, energy sources used, fresh water use, hazardous and nonhazardous waste produced and quantity of material recovered/recycled at the end of the process.

“The LCA served to really quantify the impact of our process on several KPIs. The aim was to have a clear understanding of what we are doing now, and therefore to immediately begin introducing action to improve how we work every day,” Nespolo says.

She adds that Caracol’s Heron AM system already helps mitigate environmental impact. In addition to those already mentioned, the technology produces net-shape geometry parts thereby reducing waste, operates without additional tooling or support materials, which often eliminates post-processing or assembly steps, and reduces supply chain waste by using recycled materials or via waste-free processing. The system is also said to be more energy-efficient compared to traditional fused deposition modeling (FDM) printers.

The study also provided insights into the ways the process can still be improved further, Nespolo adds. Thanks to these results, Caracol has taken on additional sustainability-minded measures like investing in solar panels to power its facilities and improving its waste management system with a goal of 100% recycled waste.

Overall, the MASAU project demonstrated the ability to flexibly manufacture custom parts using fiber-reinforced recycled materials and 3D printing for as little environmental impact as possible from a manufacturing, waste and materials standpoint, showing potential for a variety of future applications.

Related Content

CirculinQ: Glass fiber, recycled plastic turn paving into climate solutions

Durable, modular paving system from recycled composite filters, collects, infiltrates stormwater to reduce flooding and recharge local aquifers.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read MoreBio-based acrylonitrile for carbon fiber manufacture

The quest for a sustainable source of acrylonitrile for carbon fiber manufacture has made the leap from the lab to the market.

Read MoreWatch: A practical view of sustainability in composites product development

Markus Beer of Forward Engineering addresses definitions of sustainability, how to approach sustainability goals, the role of life cycle analysis (LCA) and social, environmental and governmental driving forces. Watch his “CW Tech Days: Sustainability” presentation.

Read MoreRead Next

Large-scale, robotic-mounted 3D printer aims to expand AM size limits

Italy-based Caracol has developed an extrusion-based, robot-mounted 3D printer to scale up printing capabilities for high-performance aerospace tooling and industrial parts.

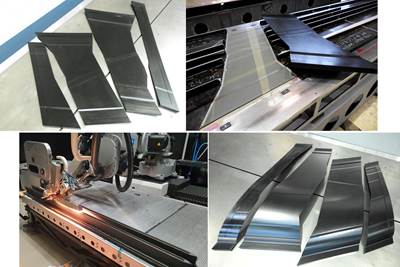

Read More3D-printed CFRP tools for serial production of composite landing flaps

GKN Aerospace Munich and CEAD develop printed tooling with short and continuous fiber that reduces cost and increases sustainability for composites production.

Read MoreCaracol AM launches new identity, celebrates composites applications

Italian supplier of Heron large format additive manufacturing (LFAM) technology showcases circular economy and aerospace applications.

Read More.jpg;width=70;height=70;mode=crop)