AVK presents its 2018 Innovation Awards

The 2018 AVK Innovation Awards were presented at the International Composites Congress (ICC) on Nov 5, chosen from more than 50 submissions.

AVK is the German professional association for fiber reinforced plastics/composites, which represents the interests of producers and processors on a national and a European level. Its services include organization of task forces, seminars and conferences, as well as providing market relevant information, including its annual composites market report.

AVK is one of the four national pillars of the umbrella organization of the German plastics converting industry (GKV) and a member of the European Composites Industry Association (EuCIA). AVK is a foundation member of Composites Germany, along with Carbon Composites e. V. (CCeV), CFK-Valley Stade e. V. (CFK-Valley) and the Working Group Hybrid Lightweight Technology at VDMA.

For years now, AVK has awarded special innovations in fiber reinforced plastics (FRP)/composites with the aim of promoting new products, processes and applications. Another prize goes to universities, colleges and institutes for outstanding scientific work in research and science. In all categories, special emphasis is placed on the topic of "sustainability".

The 2018 AVK Innovation Awards were presented at the 4th International Composites Congress (ICC) on Nov 5, chosen from more than 50 submissions. A full list of submissions and awardees can be found at: https://www.avk-tv.de/files/20181108_avkinnovationspreis2018.pdf

2018 AVK Innovation Awards Winners

BÜFA Conductive Tooling Gelcoat

An electrically conductive tool coating which contributes significantly to increasing the safety standard in composite production. If the tool is properly grounded, the leakage resistance from the tool surface to the grounding point is 106 Ω. To ensure that electrostatic charges can be safely discharged, the leakage resistance must be in the range of 106-109 Ω. The materials previously available on the market for plastic toolmaking are by definition electrical insulators (1012 Ω) and thus not able to dissipate electrostatic charges that occur when the components are demolded. The conductive characteristics of the BÜFA-Conductive-Tooling-Gelcoat surfaces are achieved by using very small amounts of carbon nanotubes (CNT). This results in decisive benefits compared to conventional antistatic additives such as carbon black or graphite.

Lightweight CFRP gripper system. SOURCE: CTC Stade.

Lightweight CFRP gripper system for robot and assembly applications

Audi AG, CTC GmbH (An Airbus Company), Airbus Operations GmbH, the Laboratory for Manufacturing Technology of the Helmut-Schmidt-University Hamburg and Volkswagen AG developed a modular, high-performance lightweight gripper system made from carbon fiber composites during a 5-year development program. This kit of modular components can be used in industrialized aerospace and automotive production and assembly systems. The new lightweight gripper system complements and partly replaces elements of the Euro Greifer Tooling (EGT) system currently used in the German automotive industry — comprising various aluminum or steel profiles and connector elements. In contrast, the new lightweight gripper system contains connector elements made out of carbon fiber SMC, complex pultruded CFRP profiles and smaller filament wound CFRP tubes.

Dieffenbacher Fibercon - Efficient IR radiation induced vacuum consolidation of tape layups in series production

The consolidation of tailored blanks is a necessary step in the process chain to achieve high mechanical properties in composite parts. The Fibercon consolidation system minimizes polymer degradation while showing capability to impregnate dry fibers as it efficiently eliminates porosity in tailored blanks. High temperature thermoplastics can also be processed without any adaptation of the system. Other benefits include the ability to consolidate tailored blanks with thickness variations and reduced energy consumption vs. conventional heating /cooling processes. In an automated production run, the tailored blanks can be demolded at an elevated temperature near the melting point such that the residual heat can be used to minimize the reheating power for the final thermoforming process — i.e., serves as blank preheat.

SOURCE: RWTH Aachen University (starting at 1:48 in video)

OrganoGlas by Institut für Textiltechnik (ITA) at RWTH Aachen University

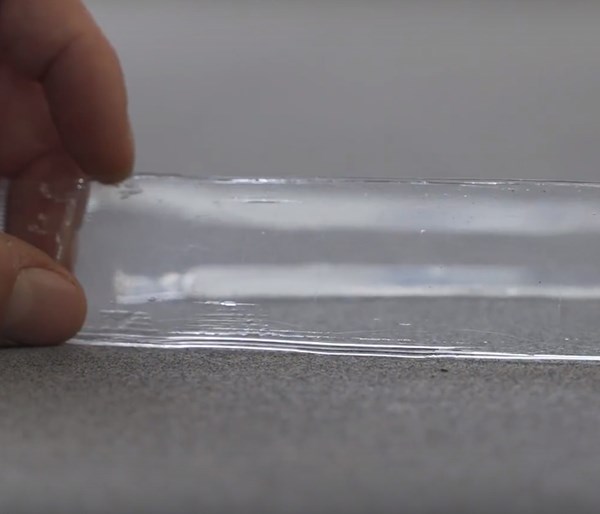

OrganoGlas — a novel and disruptive development in the field of transparent materials — is a thermoplastic fiber-reinforced composite of flat glass fibers and a transparent matrix. The production of a low-cost, formable, high-strength and transparent material not only replaces existing materials, but also opens up new applications. Compared to existing transparent solutions, OrganoGlas has significantly higher strengths at the same weight, which enables a corresponding weight reduction in automotive, aerospace and construction industry applications. The innovative material can also be reshaped and welded due to the thermoplastic matrix, making mass production of transparent FRP panels possible, which then can be molded to the desired shape. This will lead to a significant cost advantage over current solutions and close the lightweight gap in transparent materials.

Novel Hybrid Yarn: Coating of all Glass Filaments in the Spinning Process to produce a Glass Thermoplastic Fiber

ITA at RTWH Aaachen University and Institute for Lightweight Design with Hybrid Systems (ILH) at Paderborn University have developed a novel process for producing glass fiber/thermoplastic composites. Continuous fiber-reinforced thermoplastic composites (TPCs) are often made by impregnating glass fiber textiles with thermoplastic films — a process where not all of the glass filaments are bonded to the matrix plastic. As a result, the lightweight potential for TPCs is not fully realized. The new approach chosen by ITA and ILH coats the glass fibers directly with the thermoplastic (TP) matrix material during the fiber manufacturing process. In this way, all of the fiber’s filaments are individually coated, which preserves its flexible yarn character. Another advantage is the matrix plastic is only a few µm from its final location vs. current state of the art, where the TP matrix has to flow several millimeters.

FlexReha rehabilitation process by Lausitzer Klärtechnik GmbH

This novel fiber composite-based process enables structural rehabilitation of heavily-stressed sewage and water pipes made from concrete, regardless of season/time of year. There is a high demand for efficient methods to rehabilitate wastewater pumping shafts in the field, where full restoration of load-bearing capacity can be achieved throughout the year. With the FlexReha technology, a supporting glass fiber-based sandwich construction is integrated inside the degraded concrete shaft using the vacuum infusion process. A digital geometric 3D-scan enables an individual, tailor-made and resource-optimized lining and a much more efficient process vs. traditional remediation procedures using mortar — FlexReha reduces costs and implementation time by roughly 50%. The integrated heating and leakage detection system prevents release of environmentally harmful substances. FlexReha can also be applied on other above-ground or underground structures such as silos, industrial tanks, sewer pipes or biogas plants.

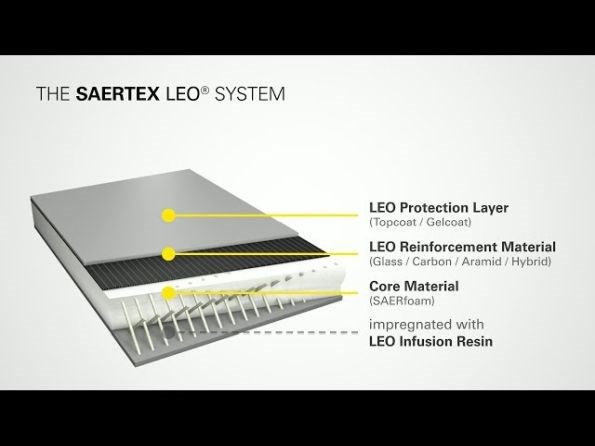

SAERTEX LEO for the flooring of 66 Deutsche Bahn ICE trains

SAERTEX LEO is an optimized noncrimp fabric (NCF) system offering high-performance fire protection for rail vehicle applications. Together with their partners SMT Montagetechnik and Alan Harper Composites, SAERTEX developed a product and successfully changed the flooring panels of 66 rail cars for Deutsche Bahn’s ICE 3 trains — updating from plywood panels to LEO composite panels. SAERTEX LEO offers a high potential for lightweight construction, a high carrying capacity and non-toxic, halogen-free materials. The SAERTEX LEO system satisfies the new European fire safety standard EN 45545-2. Moreover, the implementation and use of the SAERTEX LEO system reduces the trains’ environmental impact caused by construction and usage.

Lightweight composite/metal impeller capable or 543 m/s peripheral speed.

SOURCE: Institut für Leichtbau und Kunststofftechnik (ILK)

High performance composite radial impeller in modular design

Developed by TU Dresden’s Institut für Leichtbau und Kunststofftechnik (ILK), the combination of metallic components with fiber-reinforced composite structure to innovate hybrid designs offers considerable advantages for centrifugal fans in terms of power density, robustness, service life and degree of integration compared to conventional solutions. In the future, these will enable maximum peripheral speeds and economical production even for small quantities. In the research project “Lightweight Radial Impeller“ (LeRala) of the AiF Research Association for Air and Drying Technology (FLT), a simplified modular carbon fiber-reinforced composite/metal design for radial impellers was developed and information on its structural and failure behavior under maximum rotational load was generated in initial load tests. A peripheral speed of 543 m/s has already been achieved with the simplified functional model at a speed of 10,266 rpm. Such high peripheral speeds are difficult to achieve with metal impellers.

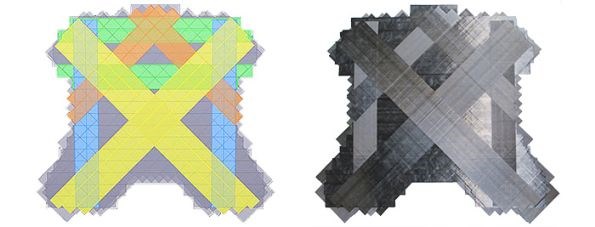

First-time-right: Efficient process development using draping simulation

Voith Composites produces the CFRP rear wall for the Audi A8 in series (up to 65,000 units per year). This highly load-bearing structural component is produced using the Voith dry direct fiber placement process (Voith Roving Applicator, VRA). During the development phase, a numerical method for forming simulation was developed, which is used in the finite element (FE) solver Abaqus/Explicit. This new simulation method makes it possible to precisely detect areas with features such as wrinkling, bridging and gaps in all 19 individual layers of the A8 CFRP rear wall and to test and quantify various process concepts and plant parameters on a virtual level. After calibration and validation based on material characterizations and tests, an industrially applicable maturity for the use in the process development of the A8 rear wall was achieved. Neither in the procurement process nor during the commissioning of the forming plant — which was designed and constructed using draping simulation — was it necessary for subsequent adjustments to the process sequence or the simulation tools. The usability of the simulation-driven process development method has not only been proven successfully for qualitative evaluation but above all as a first-time-right approach for the quantitative design of forming processes for development and series phases of high-performance, industrialized composite structures manufacturing.

Related Content

Recycling hydrogen tanks to produce automotive structural components

Voith Composites and partners develop recycling solutions for hydrogen storage tanks and manufacturing methods to produce automotive parts from the recycled materials.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read MoreRecycling end-of-life composite parts: New methods, markets

From infrastructure solutions to consumer products, Polish recycler Anmet and Netherlands-based researchers are developing new methods for repurposing wind turbine blades and other composite parts.

Read MoreWatch: A practical view of sustainability in composites product development

Markus Beer of Forward Engineering addresses definitions of sustainability, how to approach sustainability goals, the role of life cycle analysis (LCA) and social, environmental and governmental driving forces. Watch his “CW Tech Days: Sustainability” presentation.

Read MoreRead Next

VIDEO: High-rate composites production for aerospace

Westlake Epoxy’s process on display at CAMX 2024 reduces cycle time from hours to just 15 minutes.

Read MoreModeling and characterization of crushable composite structures

How the predictive tool “CZone” is applied to simulate the axial crushing response of composites, providing valuable insights into their use for motorsport applications.

Read MoreCFRP planing head: 50% less mass, 1.5 times faster rotation

Novel, modular design minimizes weight for high-precision cutting tools with faster production speeds.

Read More

.jpg;maxWidth=300;quality=90)