Fabrum supplies lightweight composite LH2 tanks for aviation, launches consortium with Airbus, other partners

New Zealand company works with FSE, GKN Aerospace to test LH2 storage and delivery system, advances zero emissions flight via Hydrogen Consortium and $23 million Series A funding.

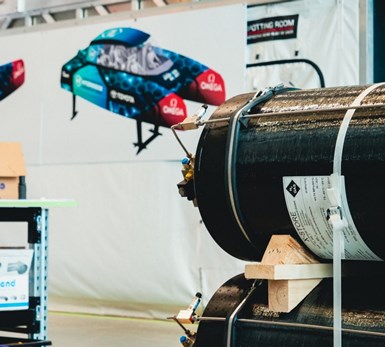

Hugh Reynolds, cofounder and technical director at Fabrum, with one of the company’s lightweight, composite liquid hydrogen tanks. “Don’t be fooled by the exterior test shell, as internally, there is a beautifully shaped, lightweight pressure vessel!” Photo Credit: Fabrum

Fabrum (Christchurch, New Zealand) was founded in 2004 by Chairman Christopher Boyle and Technical Director Hugh Reynolds. In December 2022, the company announced delivery of its first lightweight composite liquid hydrogen (LH2) tank for aviation. The tank was slated for testing in early 2023 by Filton Systems Engineering (FSE, Bristol, U.K.) to demonstrate Fabrum’s capability to deliver a complete aerospace fuel storage and delivery system. This system is designed to maximize storage efficiency (aka mass fraction = ratio of total fuel weight to total fuel system weight) and reduce boil-off gases during warm (versus cryo-chilled) refueling.

Work with GKN Aerospace

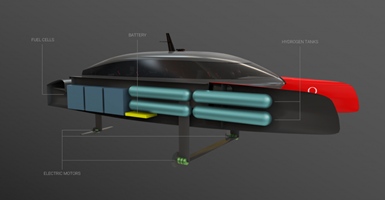

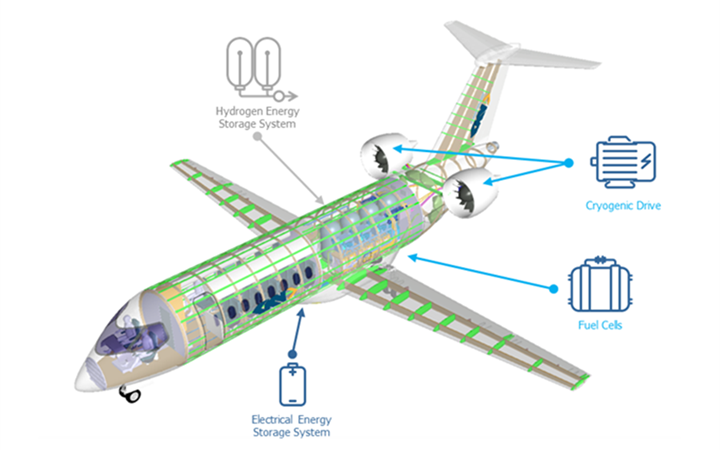

Concepts for a 19-passenger (top) and 48-passenger (bottom) H2 electric propulsion aircraft. Photo Credit: GKN Aerospace, 2021

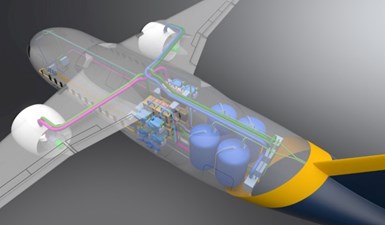

In August 2022, Fabrum announced it was working with FSE and GKN Aerospace (Solihull, U.K.) to develop technology for an end-to-end H2 fuel system. “We’re the only company in the world with capability in electrolysis, liquefaction, distribution and fuel ground storage through to aircraft fueling of onboard fuel tanks — with the ability to vaporize liquid back to gas at the right pressure and temperature for the fuel cell,” says Boyle.

GKN Aerospace announced in January 2021 its lead in the £54 million H2GEAR program, aimed to develop an LH2 propulsion system for sub-regional aircraft to be in service as early as 2026.

“We’re excited to now tie our aerospace and hydrogen systems together for actual flight and full certification with FSE. We’ve always believed hydrogen is the ideal alternative fuel for aviation, and over 17 years, we’ve developed enormous capability and understand the drivers for aviation systems.”

Boyle notes the challenges for H2-powered aviation are quite similar to those for Formula One: “It demands the best tech to achieve the outcomes the industry is after and requires high-performance, high reliability and consciousness around weight. Our technologies are a game-changer for aviation innovators and researchers — as we’re enabling liquid hydrogen production on-demand as close as possible to the point of use, storage and containment. This is a paradigm shift from liquid hydrogen produced at large-scale plants and transported to the site of use.”

Fabrum reports that it is currently manufacturing onboard fuel tanks to carry LH2 for zero-emission flights, as well as green hydrogen systems for ground-based infrastructure at airports. Both are being supported financially.

Fabrum announced its $23 million Series A financing led by London-headquartered AP Ventures with participation from Australia-based Fortescue Future Industries, Japan-based Obayashi Corp. and New Zealand-based K1W1. Fabrum plans to use the funding to expand its global presence and scale up its manufacturing capacity with a new purpose-built manufacturing facility at its Christchurch headquarters.

Photo Credit: Fabrum

The new Hydrogen Consortium in New Zealand has been launched to pioneer the commercial deployment of green hydrogen-powered, zero-emission aircraft by partners Airbus, Fortescue Future Industries (FFI), Air New Zealand, Hiringa Energy, New Zealand’s Christchurch Airport and Fabrum.

Fabrum history

Fabrum describes itself as a world leader in industrialized small- to medium-scale liquefaction systems and composite cryogenic vessels. For example, LH2 is typically stored in dewars with an inner and outer tank — typically metal — separated by multilayer insulation (MLI) in a high-quality vacuum (see blog on Cryomotive’s cryo-compressed dewar tanks). There are efforts to develop all-composite dewar tanks for onboard LH2 storage, including the NL LH2 consortium project — which is still in early stages of development — and GTL (“HyPoint partners with GTL … with ultralight LH2 tanks”) whose tanks are undergoing initial testing by two commercial customers.

Fabrum touts a history of innovation and precision engineering in composites, cryogenics and power systems, evidenced by solutions it has delivered for a variety of projects:

- Collaborated with NASA on a Liquid Air life support package for astronauts and a CO2 sublimation project for the Mars lander program.

- Worked with Rolls Royce to develop superconducting systems.

- Co-developed the world’s first electric aircraft engine for Magnix.

- Built superconducting electric motors/rotors for Safran/Airbus.

Fabrum also worked on an H2-powered foiling catamaran for the four-time champion Emirates Team New Zealand (ETNZ). The catamaran, Chase Zero, will be used as the team’s chase boat in the 37th America’s Cup in 2024. (See sidebar at bottom.)

Fabrum lists its core competencies as green hydrogen production, storage, dispensing and system integration. The company reportedly also has a strong presence in the traditional cryogenic markets of liquid nitrogen, liquid oxygen (LOX), liquid natural gas (LNG) and liquid air, with a global customer base including hi-tech research institutions, manufacturing and defense forces. In addition, it claims capabilities to design optimized composite satellite platforms with integrated propulsion, energy management, fuel tanks and structures delivering maximum payload capacity.

Forward momentum via new Hydrogen Consortium and funding

“Fabrum is a clever, innovative team doing fantastic work pioneering liquid hydrogen applications and the type of business that we want to see succeeding to help grow green hydrogen as the future fuel of choice,” says FFI CEO Mark Hutchinson. “The innovative applications being developed by Fabrum will contribute to the growth of supply and demand for green hydrogen globally and help to deliver on Fortescue’s decarbonization plan for its mining operations. Our investment provides us with a share in a company developing world-leading applications for hard-to-abate sectors like mining, heavy transport and aviation.”

Hiringa Energy

Another investor and consortium partner, Hiringa Energy, is constructing infrastructure to support New Zealand’s transition to green H2 in multiple transport sectors including aviation, marine and heavy road transport. Its first four H2 production and high-capacity refueling stations are coming online in 2023, with nationwide expansion planned in 2024. “There are green hydrogen-fueled buses, trucks, trains and boats already in service — some of them we have been refueling here in New Zealand, including the Emirates Team New Zealand chase boat,” says Andrew Clennett, CEO of Hiringa Energy. “Aircraft are a key next step, and this consortium has formed to ensure these planes have the infrastructure and hydrogen supply they will need to take off here.”

Airbus

This infrastructure is a key requirement, says Karine Guenan, vice president of the ZEROe Ecosystem for Airbus, another important consortium member with a global reach. Airbus has committed to put the world’s first H2-powered commercial passenger aircraft in service by 2035.

An ecosystem for H2 aviation is indeed the first goal of the New Zealand Hydrogen Consortium. In its first phase, to be completed by the end of 2023, the consortium will conduct research to develop a roadmap for building this ecosystem. Tasks include:

- Examining the hydrogen supply chain and its challenges;

- Assessing the local aviation market’s projected hydrogen needs to 2050;

- Developing a pathway of policies, regulations and incentives to promote the development of hydrogen aviation.

The second phase will pursue a plan to conduct H2 aircraft test flights. Consortium member Air New Zealand, for example, wants to fly its first commercial demonstrator flight by 2026 and begin replacing its Q300 Turboprop fleet with low-emissions aircraft starting in 2030.

“The consortium pulls together some of world’s best experts in green hydrogen,” says Fabrum co-founder Boyle. “Having all of these organizations around the same table will turbocharge what we all learn. Together we’ll make a big difference in taking zero emission aviation forward which is good news to anyone who wants to fly sustainably in the future.”

Funding

The most recent round of funding is also a critical milestone for Fabrum, says Boyle, “validating the technology development pathway that fellow founder Hugh Reynolds and I have built over the last 18 years. Fabrum was created to leverage Christchurch’s strong technology manufacturing history and Canterbury University’s very talented Engineering School. Bringing capability and talent together to develop world-leading technology that will genuinely enable a global shift to sustainable transportation and industry has been our core purpose.”

Related Content

A new era for ceramic matrix composites

CMC is expanding, with new fiber production in Europe, faster processes and higher temperature materials enabling applications for industry, hypersonics and New Space.

Read MoreThe potential for thermoplastic composite nacelles

Collins Aerospace draws on global team, decades of experience to demonstrate large, curved AFP and welded structures for the next generation of aircraft.

Read MoreInfinite Composites: Type V tanks for space, hydrogen, automotive and more

After a decade of proving its linerless, weight-saving composite tanks with NASA and more than 30 aerospace companies, this CryoSphere pioneer is scaling for growth in commercial space and sustainable transportation on Earth.

Read MoreCryo-compressed hydrogen, the best solution for storage and refueling stations?

Cryomotive’s CRYOGAS solution claims the highest storage density, lowest refueling cost and widest operating range without H2 losses while using one-fifth the carbon fiber required in compressed gas tanks.

Read MoreRead Next

VIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read MoreDeveloping bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read More