JEC World 2019 preview: Engel

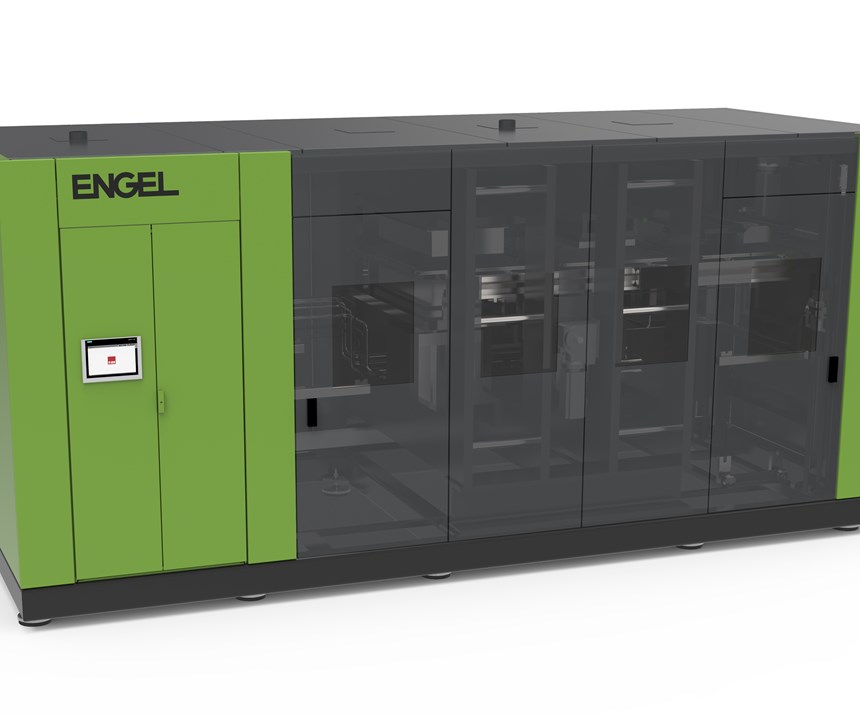

At JEC World 2019, Engel Austria is presenting its technologies for organomelt processing, in-situ polymerization, HP-RTM and flow molding with SMC.

At JEC World 2019, Engel Austria (Schwertberg, Austria) is presenting its technologies for processing of organic sheets and unidirectional tapes, in-situ polymerization, high-pressure resin transfer molding (HP-RTM) and flow molding with SMC.

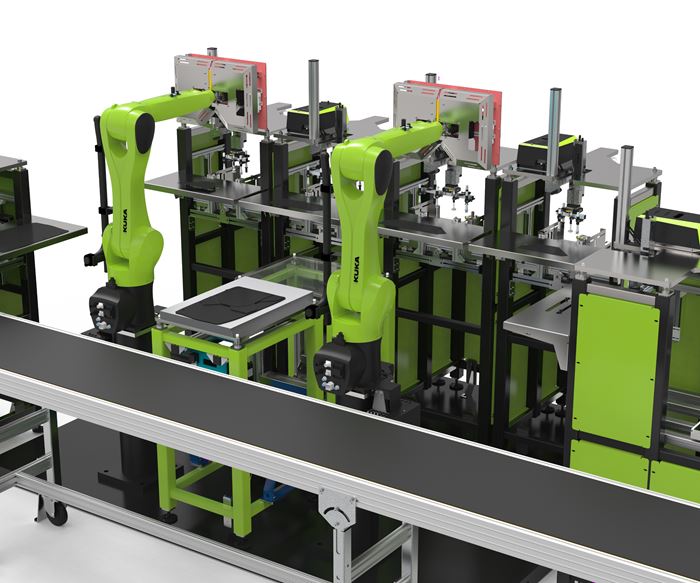

Engel is demonstrating its organomelt process at the show, with sample parts on display. The process involves the forming and functionalizing of thermoplastic fiber composite prepregs, such as organic sheets and unidirectional tapes. For example, reinforcing ribs or assembly elements can be overmolded immediately after thermoforming using a thermoplastic, said to enable an efficient and fully automated manufacturing process. In the United States, Engel says it is using this technology to mass-produce demanding structural components characterized by low weight and good crash properties. Engel supplied a duo injection molding machine, several easix articulated robots for preparing large quantities of metal inserts and handling the organic sheet, a viper linear robot and an Engel infrared (IR) oven as an integrated systems solution for automated high-volume production.

Engel organomelt technology is said to be suitable for organic sheets and unidirectional glass and/or carbon fiber-reinforced tapes with a thermoplastic matrix. To increase efficiency, the fiber stacks can be laid and consolidated inline and in the injection molding process cycle. In addition to molding machines, robots and IR ovens, pick-and-place tape stacking units with optical image processing from the in-house development and design department are used. Together with its partner Fill (Gurten, Austria), Engel has recently expanded its range to include a consolidation unit for fiber stacks with different wall thicknesses.

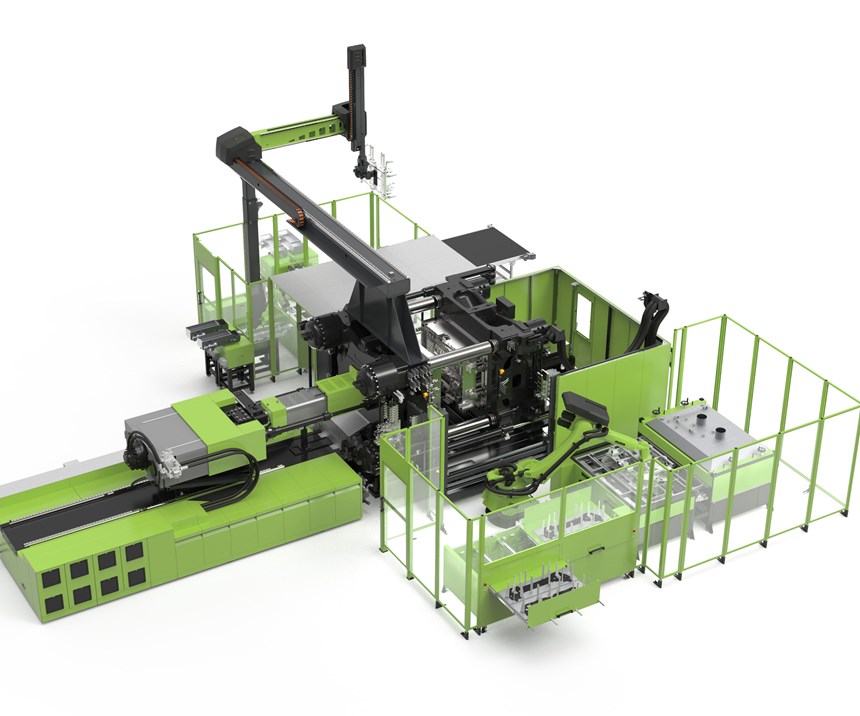

Another process on display, in-situ polymerization of ε-Caprolactam into fiber-reinforced plastic composites support structures and their functionalization in injection molding. In the Engel v-duo vertical machine, the reactive and injection molding processes take place in parallel. Thanks to the low viscosity of the melted ε-Caprolactam, preformed, dry reinforcing textiles can be wetted particularly well, according to the company, resulting in a resilient bond when polymerized to polyamide 6 (PA6). This is functionalized in a second cavity of the mold by overmolding reinforcing ribs and contours made of fiber-reinforced PA6. Engel is the first supplier on the market to rely on the ability to melt and process the solid monomer as required by in-situ polymerization, which is said to result in reduced thermal load, and therefore higher product quality. The low operating height simplifies manual work. At the same time, the v-duo enables efficient automation solutions, accelerating the industrialization of newly developed processing methods.

Also on display will be the CRP rear panels of the Audi A8, which are produced by Voith Composites (Garching, Germany) on an Engel v-duo 1700 machine using the fully automated HP-RTM process.

Engel will also be presenting gear carriers made of sheet molding compound (SMC). In a development project, Engel, together with the Institute for Polymer Product Engineering IPPE at Johannes Kepler University (Linz, Austria) as well as Hexcel (Stamford, Conn., U.S.) and Alpex (Mils, Austria), have developed a production process based on flow molding for gear carriers. The starting material is a flat carbon fiber prepreg with fiber lengths of 50 mm and a matrix of epoxy resin. Analysis of the first components is said to show weight savings and improved component properties compared to the original aluminum component.

According to Engel, flow molding with SMC is suited for a range of fiber composite components, from sophisticated visible and outer skin parts to structural components with integrated functionality. In short cycles, complex geometries and paintable surface quality are achievable. The Engel v-duo machine is suitable for SMC processing, the company says, because of its powerful measuring and control technology, flexible compression molding process and integrated parallelism control. The processing parameters are also easily adaptable to component requirements.

Related Content

ZEBRA project demonstrates closed-loop wind recycling system

Consortium partners have proven the complete recycling of thermoplastic wind turbines via two manufactured wind blades, featuring reduced operating cost, CO2 emissions.

Read MoreCirculinQ: Glass fiber, recycled plastic turn paving into climate solutions

Durable, modular paving system from recycled composite filters, collects, infiltrates stormwater to reduce flooding and recharge local aquifers.

Read MoreUnderstanding vacuum bagging layers in production, repair

Recognizing the functions of each layer in a vacuum bag schedule can help users discover what vacuum bag schedules work best for their application.

Read MoreComposites manufacturing for general aviation aircraft

General aviation, certified and experimental, has increasingly embraced composites over the decades, a path further driven by leveraged innovation in materials and processes and the evolving AAM market.

Read MoreRead Next

Plant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read MoreDeveloping bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read MoreVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read More

.jpg;width=70;height=70;mode=crop)