CFRP upgrades economy seating

First aircraft seat to use visible CFRP revolutionizes aesthetics and comfort.

Design Results

- Proprietary combination of epoxy and phenolic resins ensures FST performance.

- Durable CFRP construction provides extended six- to eight-year service life.

- Sculpted CFRP seat back with exposed woven carbon fabric gives seat a visually stunning aesthetic.

In an effort to reinvent the international flying experience for its passengers, Qantas Airways and renowned industrial designer Marc Newson set out to create a stylish and comfortable interior for its new flagship fleet of Airbus A380 superjumbo passenger jets, which handles air routes to and from Los Angeles and London, based in Sydney and Melbourne. Newson’s scope included the overall design of the cabin as well as the seating, lighting, lavatories, galleys, furniture and even cutlery and soft furnishings. Australian-born Newson, now based in London, creates innovative designs for a wide range of industries. His past projects include a Dassault Falcon 900B executive jet and the interior of a suborbital space plane for EADS Astrium (Leiden, The Netherlands).

Economy seats occupy 332 of 450 passenger places on a Qantas A380, justifying the emphasis on design and the choice of Recaro Aircraft Seating (Schwäbisch Hall, Germany) as a key partner. Recaro is experienced with carbon fiber-reinforced plastic (CFRP): Its all-carbon Comfort Line (CL) 6510 full-flat business-class seat offered Lufthansa as much as 25 percent weight savings during a fleetwide cabin upgrade.

When tasked by Qantas and Newson to create a new aircraft seat — streamlined and contemporary but focused on functionality and comfort — Recaro responded with a unique combination: a dramatically thinner profile, innovative comfort features, and a sculpted CFRP seat back with exposed woven carbon fabric to give it a visually stunning aesthetic. The resulting Recaro CL3610 economy seat has been recognized worldwide as an exemplary design and objet d’art. The seat won the 2009 Australian International Design Award and was an Excellence in Innovation finalist in the Crystal Cabin Award presentation at the annual Aircraft Interiors Expo. Additionally, the seat was shown at the select Design Real exhibition at the Serpentine Gallery (London, U.K.).

Comfort first

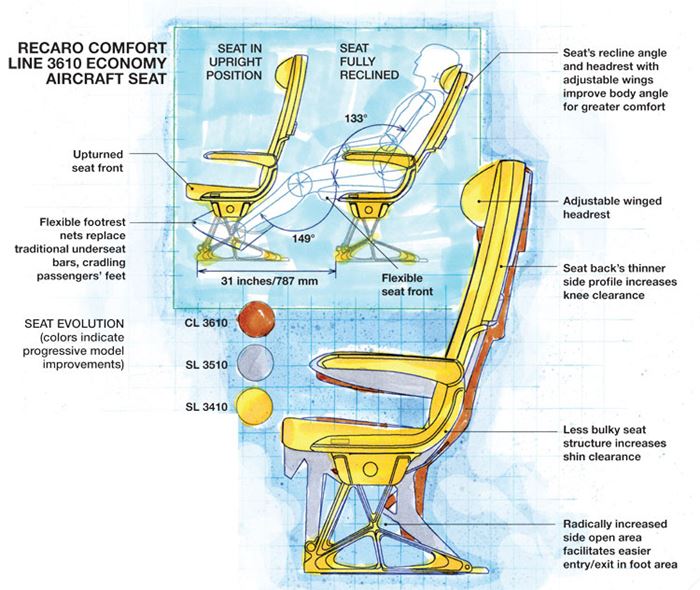

The Recaro design team used customer research and extensive ergonomic testing to develop and refine the seat’s comfort features, many of which, until now, have not been available in an economy-class seat. Its articulated seat bottom moves as the seat back reclines, enabling body angles that reduce physical tension and increase passenger comfort (similar to the mechanism used in some movie theater seats). A cushioned, flexible seat front was designed to eliminate pressure points on the legs during long-distance flights.

Footrest nets replace traditional bars under the seats in front of passengers so people can extend their feet in a comfortably supported cradle. The footrest net works in concert with the seat cushion, flexible seat front and enhanced recline from the articulated bottom to eliminate the sliding sensation often felt in economy seats. Other CL3610 features include a headrest with movable wings and — thanks to CFRP — an overall thinner design to increase the living space for each passenger (see drawing at right).

Made to be seen

The CL3610 uses CFRP in three components that are entirely visible to passengers, including the armrest covers, meal tray shell/cover and seat back or backrest. “Qantas is the first airline to choose ‘visual’ carbon fiber parts as a key feature for its economy-class seats,” says Dr. Holger Friehmelt, Recaro’s economy-class product manager. He notes that Qantas and Newson were “very keen about making sure passengers could recognize that real carbon fiber was used.”

For these three parts, Recaro chose KGPD 4006 SR prepreg supplied by Krempel GmbH (Vaihingen/Enz, Germany). The visual CFRP parts use woven reinforcements to achieve the visual effect that Qantas and Newson desired. As Friehmelt describes, “The 3-D appearance, or what we call ‘flip-flop effect’ when the laminate is seen from different angles, is not possible with parts graphically imprinted to look like carbon fiber.”

Recaro produced the CFRP parts with a nonautomated, nonaugmented, hand-layed, vacuum-bag process. The visible weave concept required a very precise, labor-intensive layup.

“The key challenge is to have no distortions in the prepreg in order to achieve the optical properties desired,” Friehmelt explains, noting, for example, that the way the prepreg is layed and molded into the corners is critical. “We also made sure the resin travels to all of the edges during cure,” he adds, an important factor for edge finishing.

Due to stringent flame, smoke and toxicity (FST) requirements for aircraft interiors, Recaro could not use a clear epoxy resin like those typically used in exposed-weave CFRP automotive seats, and because the inherently fire-resistant phenolic resins often specified for aircraft are reddish brown in color, rather than clear, a phenolic prepreg also was impractical. Instead, the oven-cured prepreg featured a proprietary epoxy/phenolic combination in which the latter contributes to the weave’s color. The combination, however, posed another challenge: “If you have too much [phenolic] resin, the surface turns a different color,” Friehmelt explains. “So to achieve the desired appearance, we had to ensure there was a uniform resin distribution.”

Invisible yet innovative

Not visible is the single CFRP beam that forms the seat’s primary load-carrying structure. The single-beam design eliminates the traditional rear beam. This not only increases the between-seat living space — particularly, knee/shin room — but it also reduces seat complexity and part count. It also helps to offset the weight of added comfort features. The beam spans the seat width, providing attachment points for all major seat components. It is manufactured by AAT Composites (Pty.) Ltd. (Cape Town, South Africa). AAT specializes in the design and manufacture of composite aircraft interior structures, with a focus on seating, and has strong ties to Recaro.

“The laminate in the beam is tailored for the lightest possible weight,” explains Friehmelt, but he notes that with an eye to passing certification tests, the layup “uses up to a dozen plies depending on location, as there is a different stress distribution in every area of the beam.” Certification requires passing 16G forward dynamic and 14G downward dynamic crash load tests. The tests are performed in Recaro’s own test facility using an apparatus similar to automotive crash-test equipment, essentially propelling a seat into a wall at a force 14 to 16 times the acceleration of gravity.

Concept-to-completion trials

Friehmelt describes several challenges in developing the CFRP seat components. “Using phenolic to meet fire/smoke/toxicity regulations was challenging in that phenolic processes differently than epoxy,” he notes. “Phenolics cure by a condensation reaction that gives off water and solvents, which can cause surface-quality issues.” Additionally, phenolic flow characteristics are not as easy to handle as those of epoxies.

Trimming also was an issue, in that the CFRP parts must have holes for mounting them to supports, but these holes must not have any burrs. “We also have open edges,” explains Friehmelt, “meaning the passengers can touch the CFRP parts on the cross-plane edges.” Thus, it was vital to develop a method for trimming the component outer edges that would eliminate any sharpness or exposed fiber ends. “We tested various trimming methods, including laser and waterjet systems,” Friehmelt recounts, “but ended up with a milling process [that used] very sharp milling heads and a proprietary deburring process.”

Another difficulty was how to attach the various metallic parts, such as seat legs, to the CFRP beam. “You cannot just rivet onto the CFRP because it will break the fibers and potentially delaminate this primary load-carrying structure,” says Friehmelt. Instead, Recaro used spacer and counter sheets so that metal plates tapped with screw threads are on both sides of the composite, enabling fasteners to screw into the CFRP without having to tap threads into the laminate.

Airline seats typically have a service life of six to eight years, so the team had to devise a way to protect the CFRP surfaces. “Aircraft typically fly 21 hours per day, 345 days per year,” Friehmelt says. “You would have to drive your car 86 years to equal the same wear and tear, assuming a few hours of driving per day.”

Not only does the seat design have to be tamper-proof, but Recaro also had to apply a clear lacquer to protect the CFRP from scratches and UV exposure because light coming in from the windows could discolor unprotected phenolic resin.

Qantas has taken delivery of six A380 aircraft. Each plane has 332 CL3610 seats in economy class and four additional seats for the crew. The airline has also recently announced an extensive upgrade of nine Boeing 747-400 aircraft with new in-flight entertainment and seats, including Economy and Premium Economy seats from Recaro that will feature the same design. Further, Airbus has announced that Recaro will supply the seats for the A350 XWB.

CFRP seats of tomorrow

Because the CL3610 was designed for comfort on long-range flights, the balance between weight and functionality was at issue. However, Recaro has recently unveiled a new Stingray concept seat that is maximized for weight reduction using CFRP and other technologies. The design is based on the company’s existing SL3510 model, a lightweight (9 kg/19.8 lb), durable and comfortable seat developed for aircraft that make flights of up to four hours in duration. Engineers shaved the Stingray weight to 5.4 kg/13.2 lb while maintaining comfort and reliability by using titanium, a new aluminum alloy and additional CFRP in the primary beam structure, which was redesigned using cutting-edge analysis. “Although the Stingray is a prototype, it is very realistic,” comments Recaro’s CEO, Axel Kahsnitz. “We conducted simulation tests to verify the weight reduction. This seat could feasibly be built and certified.”

Asked if CFRP will continue to be a material of choice at Recaro, Friehmelt responds, “It depends on whether the increased cost of CFRP vs. aluminum or vacuum-formed plastic can be offset by the reduced weight it can achieve, which has a higher value when fuel prices are up.” Airlines will pay more for lighter materials when fuel prices are high, but there is a breakeven point above which airlines cannot justify the cost. Recaro has already pushed the seat design envelope using CFRP, and it continues to look for new technology that will help meet airlines’ demands for shorter lead times, increased flexibility (seating reconfiguration) and lower cost while maintaining lightweight structural and FST performance. No easy feat, but definitely an opportunity.

Related Content

Jeep all-composite roof receivers achieve steel performance at low mass

Ultrashort carbon fiber/PPA replaces steel on rooftop brackets to hold Jeep soft tops, hardtops.

Read MoreBio-based acrylonitrile for carbon fiber manufacture

The quest for a sustainable source of acrylonitrile for carbon fiber manufacture has made the leap from the lab to the market.

Read MoreThe potential for thermoplastic composite nacelles

Collins Aerospace draws on global team, decades of experience to demonstrate large, curved AFP and welded structures for the next generation of aircraft.

Read MorePEEK vs. PEKK vs. PAEK and continuous compression molding

Suppliers of thermoplastics and carbon fiber chime in regarding PEEK vs. PEKK, and now PAEK, as well as in-situ consolidation — the supply chain for thermoplastic tape composites continues to evolve.

Read MoreRead Next

All-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read MoreDeveloping bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read More