Defense

Carbon fiber market: Gathering momentum

All signs point to increasing demand from many market sectors. Will capacity keep pace?

Read MoreComposite solutions: Cutting cost of nuclear-powered subs

Composite-for-metal substitutions cut expense, boost production for Virginia-class submarine program.

Read MoreThe military ground vehicle armor market: Strategies for coping with decline

Marcia Price (Vector Strategy Inc., Southern Pines, N.C.) serves up predictions for the ground vehicle armor market and offers armor manufacturers a strategy for dealing with the current downturn.

Read MoreAntiballistic composites: Course corrections

Changes in the military theater are rewriting the script for composites in ballistic protection applications.

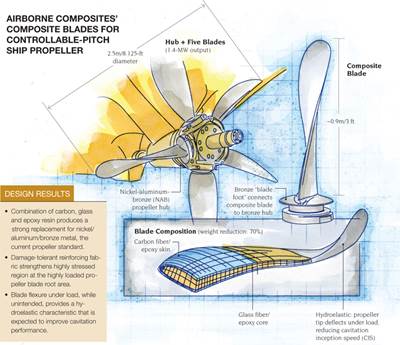

Read MoreComposite propeller for Royal Navy minehunter

Composite-for-metal replacement brings multiple benefits.

Read MoreRe-inventing the RHIB: Shock Mitigation

The U.S. Navy’s search for a lighter, load-absorbing rigid-hulled inflatable boat may end with this unconventional design.

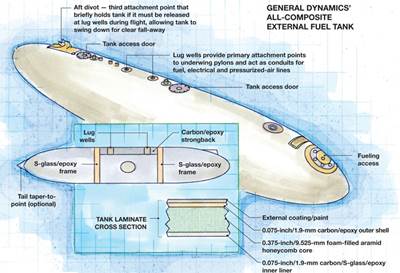

Read MoreCarrier-capable, all-composite external fuel tank

Legacy product positions builder for a shot at an F-35 contract.

Read MorePortable wind turbine powers the warrior

DARPA-financed program puts wind energy to use for battery and system recharging.

Read More