Epoxies

Green resins: Closer to maturity

As more players approach the market, R&D expands, but overall market growth in the composites arena is still slow but steady.

Read MoreNew 250°F/120°C No Oven No Autoclave epoxy

Designed for room-temp infusion and filament winding with 2-hr no-heat-added cure or 15-30 min heated cure without post-cure for flexible processing of marine, industrial and energy structures.

Read MoreComposites tackle concussions

The launch of the first commercial composite football helmet and new research thrusts show FRPs could play a critical role in mitigating head injuries.

Read MoreReport from IBEX 2015

As always, IBEX supplied new products, processes and education, not only to boatbuilders, but to the composites industry overall.

Read MoreCFK-Valley Stade Convention 2015 report

The composites industry in Germany is preparing for the 4th Industrial Revolution.

Read MoreAVANCO: Driving the industrialization of CFRP structures

The AVANCO Group is producing high-quality CFRP parts into a wide array of applications from six production facilities in Germany and the US.

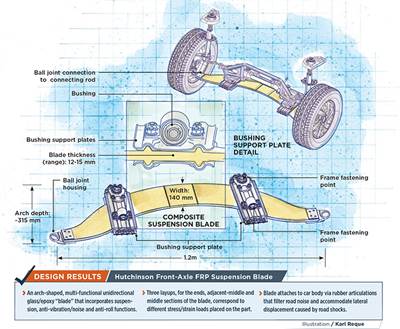

Read MoreAutomotive front axle: A glass act

The development of glass-fiber reinforced car axle is a sign of the new, expanded role composites will play in the design of future automobiles.

Read MoreAeroengine Composites, Part 2: CFRPs expand

Proven in fan blade/case applications, carbon fiber-reinforced polymers migrate to previously unanticipated destinations nearer the engine “hot zone.”

Read MoreAutomotive composites: Thermosets for the fast zone

Epoxies continue to be developed for faster cure to meet automotive production rates.

Read More