Out of Autoclave

Resins for the Fast Zone

An automotive supplier must have the ability to produce a composite part in a minute, or at least in minutes — not hours or days, the norm for composites in most other industries. Meeting that part-per-minutes goal is a huge hurdle that a few composite fabricators have cleared, and many more are involved in development efforts, with OEM or Tier partners. CompositesWorld reviews how resin suppliers have evolved their products for this critical market.

Read MoreAutomation and rapid processing dominate at JEC Americas

Highlights include Fiber Patch Preforming, automated potting and insert equipment and processes delivering composite parts in minutes.

WatchA growing trend: 3D printing of aerospace tooling

Toolmakers and OEMs are embracing additive manufacturing for customized, rapid tools, masters and jigs.

Read MoreThermosets vs. thermoplastics: Is the battle over?

Dale Brosius, the chief commercialization officer for the Institute for Advanced Composites Manufacturing Innovation (IACMI) and a regular CW columnist, sees a shift in the industry from infighting between proponents of thermoset and thermoplastic composites to a healthier competitive atmosphere that serves to make composites overall more competitive with legacy materials.

Read MoreEngel: Full speed ahead on composites R&D

CW attended the Engel Symposium 2015 and visited its Technology Center for Lightweight Composites in St. Valentin, Austria.

Read MoreSummer...time for an air show

Highlights from the 2015 edition of the Paris Air Show, and what to look for at the upcoming EAA AirVenture air show in Oshkosh next month.

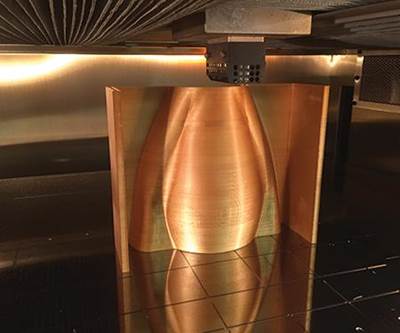

Read More3D Printing Moves Into Tooling Components

Some pundits predict that 3D printing, or additive manufacturing (AM), will change our world forever. While that may yet be, one thing is clear: The growth of 3D printing over the past two decades has wrought significant change in composites tooling. Although AM’s most obvious advantage is direct part production without tooling, the growing trend in the aerospace and automotive sectors at present is its use for fast, on-demand builds of mold tools to keep pace with accelerating composite part design cycles and demand for faster overall part processing speeds.

Read MoreOpportunities for composites at AIA 2015

Key trends and new products on the floor at this year's American Institute of Architects show.

Read MoreThermoplastic composites technology: A view from Europe

For this Dutch consortium, bringing the manufacturability of thermoplastic materials to maturity is the goal in concert with OEMs, materials and equipment supplier members.

Read More