Automation and rapid processing dominate at JEC Americas

Highlights include Fiber Patch Preforming, automated potting and insert equipment and processes delivering composite parts in minutes.

I attended the JEC Americas 2015 show, June 2-4, in Houston, TX, US. Though it was a small show, I can always find new developments in composites and companies I have not seen before that remind me of why I love working in this industry.

|

|

|

Cevotec exhibited various parts made with Fiber Patch Placement at JEC and Hannover Messe, including a carbon fiber composite bike saddle. SOURCE: Cevotec.

In the Innovation Awards section, Cevotec (Garching bei München, Germany) was recognized for its further development of the patented Fiber Patch Placement (FPP) technology (see “Airbus A350 Update: BRaF & FPP”) it has licensed from Airbus Group (previously EADS Innovation Works, Ottobrunn, Germany). According to Cevotec, FPP enables automated production of advanced carbon fiber products. It increases mechanical performance by load path-optimized fiber orientation, saves material scrap and process time by net shape 3D preforming and guarantees highest part quality by online camera control. A spinoff from Technische Universität München (Munich, Germany), Cevotec was founded in Feb. 2015 by Yannick Blössl, Thorsten Groene, Neven Majic and Felix Michl. The company exhibited at JEC Europe 2015 (Mar 10-12, Paris, France) and at Hannover Messe (April 13-17, Hannover, Germany). Check back next week for a more detailed blog based on my upcoming interview with Cevotec’s founders.

RUAG Space (Zurich, Switzerland; renamed to Beyond Gravity) was recognized for its development of a new insert which allows automated placement into composite sandwich panels for satellites, significantly reducing production time and cost as well as panel weight. The inserts are used for attaching equipment such as instruments or sensors, with more than 25,000 used in a typical communications satellite. Until now, all of these have been installed manually.

RUAG Space has developed an Automate Potting Machine (APM) which drills holes, applies special adhesive and locates inserts into honeycomb-cored panels. SOURCE: RUAG Space.

RUAG’s innovation comprises the insert itself, the positioning process and the newly developed Automated Potting Machine (APM). RUAG’s APM cuts the panels, drills holes for the inserts, applies specially designed adhesive to the new insert and puts it in position. Automation of the insert process has been demonstrated to work reliably in industrial applications.

The Quilted Stratum Process automates layups to deliver net shape preforms as part of France's national high-volume production line for composite parts.

SOURCE: Cetim and Pinette Emidecau Industries.

Cetim (Technical center for the mechanical industry, Senlis, France) was lauded for its innovative Quilted Stratum Process which automates layup to deliver net shape preforms ready for subsequent molding and assembly. Resulting from a partnership between Cetim, Pinette Emidecau Industries (Chalon sur Saone, France), Loiretech (Mauves-sur-Loire, France) and Compose (Bellingnat, France), this and the subsequent Resin Transfer Molding (RTM) module are the first two pieces of the French national high-volume production line for composite parts whose goal is to develop “seamless” — i.e., from fiber to finished product — production of carbon-fiber thermoplastic composite parts and hybrid composite parts with a cycle time of approximately one minute. This “national” tool is supported by a broad set of stakeholders, including Arkema (Colombes, France), Faurecia (Nanterre, France), PSA-Peugeot Citroën (Paris, France), Renault (Boulogne-Billancourt, France) and Solvay (Brussels, Belgium), as well as various universities and technical research centers.

The Quilted Stratum Process reportedly achieves the goal of high performance, low cost and short cycle time simultaneously, including:

- Production of variable thickness parts with customized multi-layer orientations;

- Use of multiple fibers and polymers from hybrid pultruded tapes;

- Cycle time from 40 to 90 seconds including preform fabrication, heating, transfer and thermoforming/overmolding for high volumes;

- Competitive production economics within the additional cost limit of €5/kg saved.

The Quilted Stratum Process partners imagined the concept two years ago and now provide an automatic production line ready for developing and producing industrial prototypes for the Automotive and Aerospace markets.

This UAV fairing is reportedly the first to use ATL BMI prepreg with

ROHOCELL foam and OOA cure. SOURCE: CompositesWorld.

Evonik ROHACELL (Essen, Germany), Raptor Resins (Celina, TN, US), Hexcel (Stamford, CT, US) and Spirit AeroSystems (Wichita, KS, US) received an award for out of autoclave (OOA) Advanced Tape Placement of bismaleimide (BMI)/IM7 carbon fiber prepreg and ROHACELL HERO polymethacrylimide (PMI) structural foam core for an unmanned aerial vehicle (UAV) fairing.

The part was manufactured using Raptor’s OOA BMI-1/IM7 prepreg with fiber areal weight of 145 g/m2 and resin content of 32%. Spirit AeroSystems performed the automated tape laying (ATL) with 0.25-inch wide slit tape placed over 71ROHACELL HERO core, followed by curing in an oven. According to the partners, this is the first time a BMI part has been made with ATL and OOA cure, and also the first use of ATL with ROHACELL foam core.

|

|

|

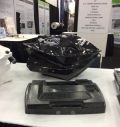

The Bullray is reportedly the first fully autonomous, amphibious, waterproof and portable VTOL tri-copter which uses quasi-isotropic molding compound to produce its CFRP fuselage in less than 5 minutes. SOURCE: Rapid Composites and CompositesWorld.

Rapid Composites, based in the Sarasota, FL area, was applauded for its Bullray amphibious, vertical takeoff and landing (VTOL) unmanned aerial system (UAS). Reportedly the first fully autonomous, amphibious, waterproof and portable VTOL tri-copter, the Bullray’s fuselage can be molded in less than 5 minutes using quasi-isotropic carbon fiber molding compound and Rapid Composites’ proprietary high-speed and automated molding equipment. The Bullray can be optionally configured as a quad- or penta-copter and at 8 kg without payload, is easy to transport via shoulder sling (push button folding booms). The Bullray also uses patented pitch carbon fiber pin-fin and airfoil heat sinks for rapid heat transfer and longer high-performance in-flight service.

Related Content

Large-format 3D printing enables toolless, rapid production for AUVs

Dive Technologies started by 3D printing prototypes of its composite autonomous underwater vehicles, but AM became the solution for customizable, toolless production.

Read MoreBroetje-Automation demonstrates rCF placement via AFP

Through the ScrapSeRO project, the system integrator and machine builder successfully processed recycled composites, in addition to more traditional materials, via its highly flexible Staxx One system.

Read MoreModular, robotic cells enable high-rate RTM using any material format

Airborne’s automated ply placement systems at Airbus, GKN Aerospace and Teijin Automotive Technologies aim to maximize flexibility and intelligent automation.

Read MoreBio-inspired EV underbody panel developed by TPI Composites, Helicoid Industries

Composite underbody panel for battery pack protection, made of stacked multiaxial noncrimp fabric, will serve high-volume commercial and automotive markets.

Read MoreRead Next

Thermoplastic composites technology: A view from Europe

For this Dutch consortium, bringing the manufacturability of thermoplastic materials to maturity is the goal in concert with OEMs, materials and equipment supplier members.

Read MoreVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read More