Processes

Gas-Assisted Injection G.E.T.S BMC Costs Down

Gas Evacuation Technique (G.E.T.) produces hollow components with long, narrow profiles, saving material and shortening cycle times.

Read MoreBoeing sets pace for composite usage in large civil aircraft

Innovative use of international supplier base to revolutionize aircraft manufacture.

Read MoreAutoclavable foam core resists bucking and shortens production cycle on launch vehicle interstage

The February 26 launch of the Multi-functional Transport Satellite-1 Replacement (MTSAT-1R) communications satellite in Japan was successfully accomplished by the H-IIA No. 7 launch vehicle, developed by the Japan Aerospace Exploration Agency (JAXA). The H-IIA is Japan's heavy rocket, first launched in 2001. Many of

Read MoreComposite fan blade containment case

Innovative use of carbon-fiber braid yields a ductile structure that resists blade impact.

Read MoreCOMPOSITES AND CONCRETE

The benefits of composite materials are well established in concrete reinforcement and construction.

Read MoreDurable thermoplastic ski-on-wheels takes on tough trails

GateSkate Inc. (Richland, Wash.) has created a new sport with its TrailSkate, an all-terrain inline skate that is, in effect, a ski on wheels. Equipped with 80-psi air-filled tires fore and aft, the TrailSkate is designed to travel over a range of surfaces, including asphalt, dirt, gravel, grass and mountain trails.

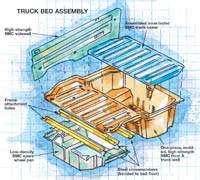

Read MoreInside-the-box thinking pays off for Honda

New Ridgeline pickup features innovative composite box with first-ever molded-in trunk.

Read MoreAt the top and still climbing

Trek Bicycles' OCLV manufacturing method shortens cycle times and optimizes compaction in molded carbon fiber-bike frame components.

Read MoreComposites take off ... in some civil helicopters

Slowed by certification requirements, composites nevertheless are finding their way into the fuselages and rotor blades of commercial helicopters.

Read MoreComposite design selected for salmon tracking antenna

Tough and affordable ultrathick laminate the solution for fish counting application.

Read More