Novel woven UD fabrics are designed for versatility, reliability

CAMX 2024: Zoltek introduces PX35UD0300EPW and PX35UD0600EPW, carbon fiber fabrics providing easy handling that have the potential to meet the evolving needs of composite applications.

Share

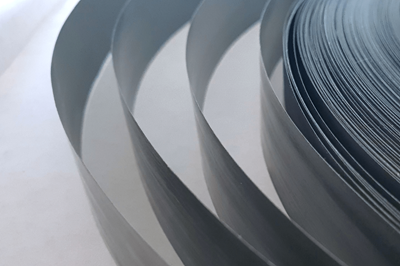

Zoltek (Bridgeton, Mo., U.S.) is presenting its latest unidirectional (UD) woven fabric innovations, the PX35UD0300EPW and PX35UD0600EPW, which stand out distinctly from the company’s existing PX35 series, offering a range of features and advantages designed to meet the evolving needs of the composites industry.

Unlike previous offerings, PX35UD0300EPW and PX35UD0600EPW are woven, heat-bonded UD fabrics using a distinctive stabilization technique for easy handling during wet layup. The weft bonding yarn enables custom cutting on-site to minimize scrap. This structure enhances ease of handling and increases the fabric’s strength and stability. The woven nature ensures clean and efficient cutting minus frayed edges.

The fabrics are comprised of Zoltek PX35-1 (multi-compatible with epoxy and vinyl ester) and PX35-7 (compatible with vinyl ester) 50K continuous tow carbon fiber, enhancing performance and durability.

According to Zoltek, the U.S.-made PX35UD0300EPW and PX35UD0600EPW fabrics offer a strategic advantage in the North American market, particularly in government-supported and defense projects. Previously, Zoltek says it only offered stitched UD types; this advancement, however, enables the company to target infrastructure applications more effectively and provide shorter lead times.

Other potential applications are listed, including reinforcing concrete structures; lining pipes, tanks and silos; and constructing water reservoirs, tunnels, bridges, chimneys and columns.

Zoltek is actively seeking to engage with companies qualified to use fiber-reinforced polymer (FRP) systems where its material can seamlessly replace currently used materials. Additionally, Zoltek aims to attract businesses looking to develop their own FRP systems with their own resins.

Related Content

-

Sulapac introduces Sulapac Flow 1.7 to replace PLA, ABS and PP in FDM, FGF

Available as filament and granules for extrusion, new wood composite matches properties yet is compostable, eliminates microplastics and reduces carbon footprint.

-

Plant tour: Albany Engineered Composites, Rochester, N.H., U.S.

Efficient, high-quality, well-controlled composites manufacturing at volume is the mantra for this 3D weaving specialist.

-

The potential for thermoplastic composite nacelles

Collins Aerospace draws on global team, decades of experience to demonstrate large, curved AFP and welded structures for the next generation of aircraft.

Related Content

Sulapac introduces Sulapac Flow 1.7 to replace PLA, ABS and PP in FDM, FGF

Available as filament and granules for extrusion, new wood composite matches properties yet is compostable, eliminates microplastics and reduces carbon footprint.

Read MorePlant tour: Albany Engineered Composites, Rochester, N.H., U.S.

Efficient, high-quality, well-controlled composites manufacturing at volume is the mantra for this 3D weaving specialist.

Read MoreThe potential for thermoplastic composite nacelles

Collins Aerospace draws on global team, decades of experience to demonstrate large, curved AFP and welded structures for the next generation of aircraft.

Read MoreManufacturing the MFFD thermoplastic composite fuselage

Demonstrator’s upper, lower shells and assembly prove materials and new processes for lighter, cheaper and more sustainable high-rate future aircraft.

Read MoreRead Next

Zoltek, A + Composites present novel CFRTP UD tape

50K carbon fiber tow impregnated with polypropylene features 50 µm thickness, offers potential for weight savings and increased mechanical performance.

Read MoreDeveloping bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read More