JEC World 2019 briefs

JEC briefs on Bindatex, FILL, Solvay, Henkel, Web Industries, Cobra, PolyOne, GKN Fokker, Thomas Technik + Innovation and Hyosung Advanced Materials.

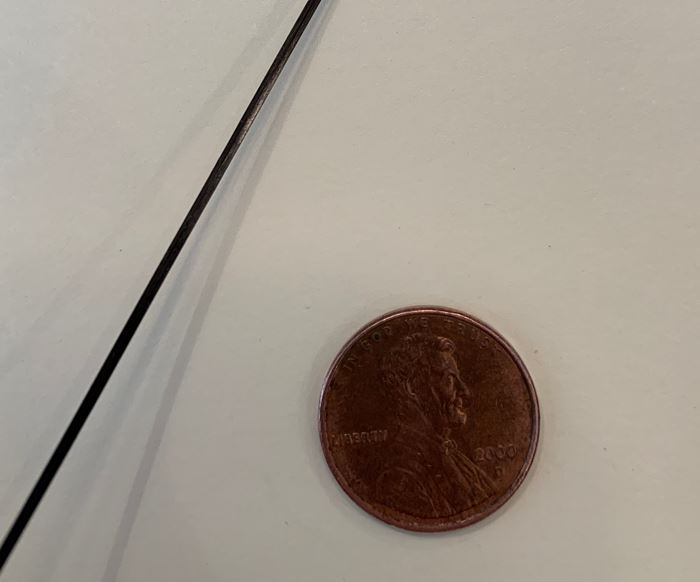

Bindatex

Tape-slitting specialist Bindatex (Bolton, U.K.) showed at its stand a 1-millimeter-wide carbon fiber/PEEK tow it had slit for a 3D printing application. The company has recently moved into a new 8,000-square-foot plant north of Manchester, U.K., and is working on slitting technologies for thermoset and thermoplastic tapes, including some dry fiber slitting.

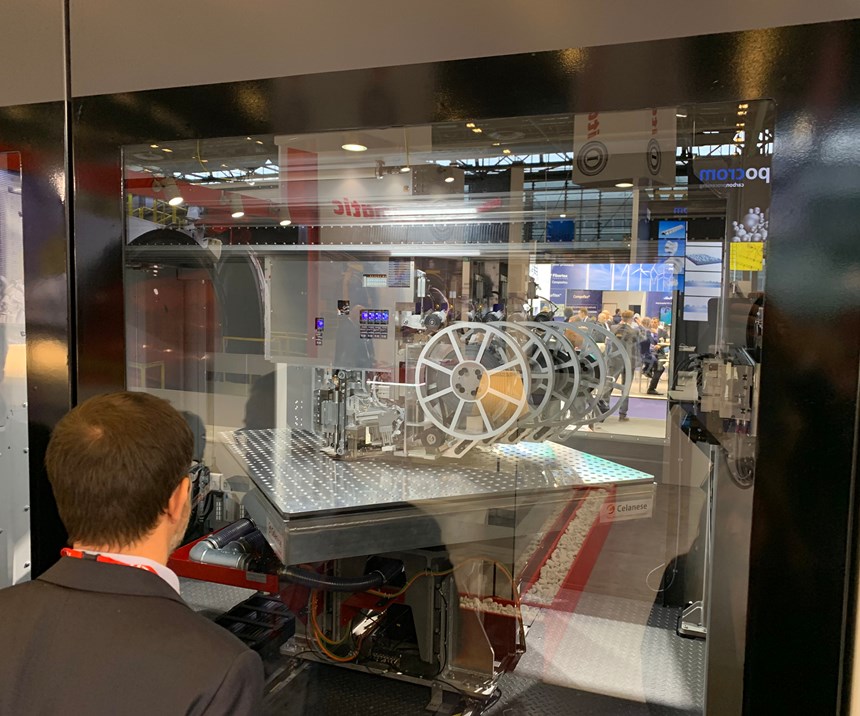

Fill

Fill Gesellschaft GmbH (Gurten, Austria) attracted much attention with its new Multilayer 16-8/50, a multi-creel tape laying machine for high-volume automotive and aerospace applications. The machine features up to 16 side-by-side, rail-mounted creels, each one laying down 50-millimeter-wide tapes on a table that offers x, y and z motion capability.

Solvay

Solvay Composite Materials (Alharetta, Ga., U.S.) emphasized at the show new technology it is developing to automate prepreg cutting, kitting, sorting and placement for compression molding applications. The system uses Double Diaphragm Forming (DDF) technology previously developed by Solvay and expected to be ready for commercial application by mid-2019. Richard Hollis, applications research team lead at Solvay, says the automation is compatible with any Solvay resin system. He also says that Solvay, through its Application Center in Heanor, U.K., will work with customers to develop and customize the automation for a specific application, and then turn it over to the customer for production.

Henkel

Resin and adhesives specialist Henkel (Düsseldorf, Germany) noted at JEC that it is seeing, in the automotive industry, most interest in applying its materials to leaf springs and battery enclosures. Echoing comments heard at Hexion, Henkel officials noted that the cost of composite materials, and manufacturing infrastructure concerns, are limiting composites penetration with automotive OEMs. That said, Konrad Brimo, senior business development manager at Henkel, said the growth of EV does open the door for composites use in new or non-traditional applications. “EV manufacturers are interested in losing weight,” he said, noting that reduced vehicle mass for EVs translates directly into longer battery range.

New from Henkel are additions to the Loctite MAX resin lineup. Loctite MAX5 NexGen is a two-component epoxy-based resin with a Tg of 200°C and a toughness of K1C >1.1. It is compatible with all liquid molding processes. Loctite MAX6 offers a step up in performance, with a Tg of >270°C and a toughness of K1C >1.0. Both resins are targeted toward the OEM and Tier 1 composite wheels market

In aerospace, Henkel introduced a new liquid shim product that is designed to provide easy filling and fast cure in large-gap (3 millimeters) applications. In addition, Henkel is opening a new aerospace paste and film manufacturing facility in Spain in June 2019.

Web Industries

Tape-slitting and cutting/kitting specialist Web Industries (Marlborough, Mass., U.S.) is in the process of integrating Omega Systemes, its most recent acquisition. France-based Omega provides tape slitting, cutting and kitting services out of two facilities for aerospace and other applications and represents, for Web, a significant step into the EU. Kevin Young, VP corporate development, and Mark Pihl, president and CEO of Web, said Omega was attractive because it offers a small but highly skilled work force and provides Tier 1 access to Airbus in Nantes, France. Also, Web Industries, which is a member of the the National Composites Centre (Bristol, U.K.), will make available the R&D competency of Omega to support new developments. “We intend to use Omega to expand our presence in the EU,” said Young. “It will be our main European facility for us to strategically expand existing business and develop new customers.” Young also suggested that Web is evaluating potential expansion of its North American business into cutting and kitting of consumables for auxiliary products.

Cobra International

Composites fabricator Cobra International (Chonburi, Thailand) is celebrating its 40th year in business in 2019 and at JEC announced expanded capabilities for automotive and aerospace manufacturing. As part of that expansion, Cobra has installed a new 5-by-2.5-meter autoclave in its 100,000-square-meter plant in Thailand. On its stand at JEC, Cobra featured several products to demonstrate the company’s fabrication capabilities, including a carbon fiber/Innegra/EPS sandwich laminate for the Flite Board, a motorized foiling surfboard that retails for $10,000.

PolyOne

Thermoplastic resins specialist PolyOne Advanced Composites (Avon Lake, Ohio, U.S.) featured the Pathfinder 2, a glass fiber/carbon fiber/epoxy prosthetic foot manufactured via pultrusion using technology originally developed by Gordon Composites, a subsidiary of Polystrand, which PolyOne acquired a few years ago. The material conveys to the foot fatigue properties that are particularly advantageous. PolyOne also featured an injection molded carbon fiber/TPU integrated riser and rail structure for a crossbow. It offers 40 percent weight reduction compared to its predecessor.

GKN Fokker

Thermoplastic aerocomposites specialist GKN Fokker (Hoogeveen, The Netherlands) received much attention in its stand for the Gulfstream fuselage panel it exhibited, demonstrating double-curvature formability in a highly loaded aerostructure (see photo). The carbon fiber/PEKK panel, made with Solvay’s APC (PEKK-FC), featuring AS4 carbon fiber, will be inserted into a metallic fuselage for a forthcoming Gulfstream business jet capable of near-supersonic speeds. The panel’s performance in that structure will be evaluated by Gulfstream, with an eye toward greater thermoplastics use in subsequent programs. As such, said Arnt Offringa, director of R&D at GKN Fokker, the panel represents the first step of many in the potential development of a fully thermoplastic aircraft fuselage.

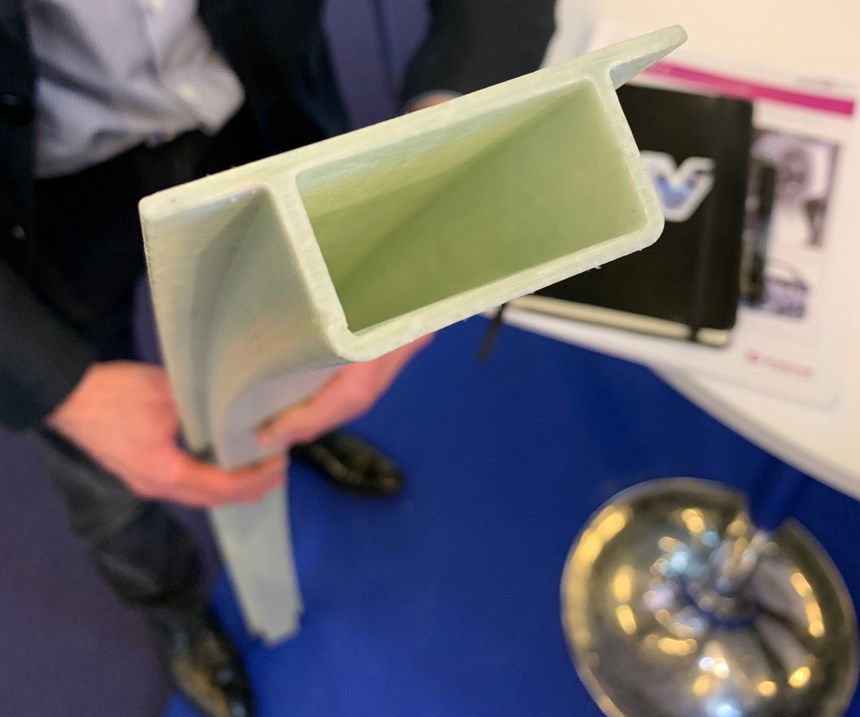

Thomas Technik + Innovation

Pultrusion equipment specialist Thomas Technik + Innovation (TTI, Bremervoerde, Germany) exhibited a curved, pultruded glass fiber/acrylic automotive bumper fabricated for a production vehicle on one of its machines by composites fabricator Shape (Grand Haven, Mich., U.S.). Sebastian Mehrtens, senior sales engineer at TTI, says the composite bumper is made possible by the company’s specialty pultrusion equipment, which allows for quick fabrication of curved structures. Further, he notes that the composite bumper bests its steel and aluminum competitors in weight and crash performance, the latter of which can be tuned by altering fiber orientation. The machine TTI sold to Shape offers a 1-hour die/material change, auto start and minimal operator intervention.

Hyosung Advanced Materials

Carbon fiber manufacturer Hyosung Advanced Materials (Seoul, South Korea) introduced at JEC its new H3065 fiber, an ultrahigh-strength, intermediate modulus material designed for Formula 1, pressure vessels and rocket motor case applications. This 12K tow carbon fiber has a tensile strength of 6,400 MPa, tensile modulus of 290 GPa, elongation of 2.2 percent and density of 1.77 grams per cubic centimeter. Hyosung also reiterated the news, announced in February, that it is spending $41.5 million to expand carbon fiber production capacity at its JeonJu, South Korea, facility. The expansion, says the company, is expected to support growth in industrial markets such as compressed natural gas and hydrogen fuel cell vessels, as well as primary and secondary aerospace structures.

Related Content

Plant tour: Middle River Aerostructure Systems, Baltimore, Md., U.S.

The historic Martin Aircraft factory is advancing digitized automation for more sustainable production of composite aerostructures.

Read MoreNext-generation airship design enabled by modern composites

LTA Research’s proof-of-concept Pathfinder 1 modernizes a fully rigid airship design with a largely carbon fiber composite frame. R&D has already begun on higher volume, more automated manufacturing for the future.

Read MoreCryo-compressed hydrogen, the best solution for storage and refueling stations?

Cryomotive’s CRYOGAS solution claims the highest storage density, lowest refueling cost and widest operating range without H2 losses while using one-fifth the carbon fiber required in compressed gas tanks.

Read MoreWelding is not bonding

Discussion of the issues in our understanding of thermoplastic composite welded structures and certification of the latest materials and welding technologies for future airframes.

Read MoreRead Next

Developing bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read More