Thermoplastic composite wings on the horizon?

OUTCOME, a project under the Clean Sky 2 program, aims to industrialize out-of-autoclave thermoplastic primary aerostructure.

Thermoplastic composites in aircraft structure have long been scrutinized, because this class of materials has the potential for fast forming, weldability, inherently superior fatigue performance and fire/smoke/toxicity (FST) properties. Considerable research has been funded by OEMs Airbus (Toulouse, France) and The Boeing Co. (Chicago, IL, US) in everything from tail to wing to fuselage structures. As a result, smaller thermoplastic composite parts, such as clips and cleats and interior structures, have been adopted, and aerostructures are currently in series production, including aircraft floor panels and flight-critical structures, such as the Airbus wing leading edges on several models. Further, the vertical tail plane on the Gulfstream Aerospace (Savannah, GA, US) G650 is a thermoplastic composite construction. (See the Side Story below and click on "Gulfstream 650 tail rudder features carbon fiber/PPS" under "Editor's Picks" at top right.)

A big hurdle, however, has remained: How to cost-effectively manufacture larger thermoplastic aerostructures — wingskins and fuselage sections — with acceptable part porosity, out of the autoclave.

Such technology is being investigated by aerospace entities concentrated in Spain, in a series of research projects funded by Airbus Defense and Space (ADS, Getafe). The Fundacion para la Investigacion, Desarrollo y Aplicaciones de Materiales Compuestos (FIDAMC), located near Getafe, has demonstrated that carbon fiber/thermoplastic wing structure can be directly manufactured via automation without autoclave consolidation, reducing processing steps and ultimately, part cost. Its latest research vehicle, called OUTCOME (OUT of autoclave COMpositE wing), aims to eventually ground test and then fly a thermoplastic composite wing structure, says Fernando Rodríguez Lence, FIDAMC’s senior composites expert.

OUTCOME will be funded by Clean Sky 2, a massive, European public/private partnership that brings together companies, universities, public laboratories and the European Commission through 2024 with a budget of €4 billion (US$4.56 billion). Clean Sky 2’s ultimate goal is to develop and demonstrate civil aircraft technologies that maximize fuel efficiency and cut aircraft emissions and noise.

Thermoplastic AFP

FIDAMC has investigated its large-part, out-of-autoclave (OOA) thermoplastic composite technology over several years, in four previous projects aimed at developing automated lamination with laser-beam heating, in-situ consolidation and co-consolidation of complex parts, using CNC fiber placement equipment from MTorres (Torres de Elorz, Navarra, Spain). Work began with the TARGETCENIT Program in 2010, which produced flat panels. ICARO, funded by the Spanish Industry and Innovation Ministry and also part of CENIT, produced more panels as well as more complex structures, and investigated methods for co-consolidation. The Green Regional Aircraft (GRA) project, concluded in 2015, and the most recently completed Clean Sky ISINTHER (Industrialization Set up for In Situ Consolidation Process in Thermoplastics) project, have enabled FIDAMC to develop an in-situ manufacturing process, says Rodriguez. Now, under the Clean Sky 2 OUTCOME project, the previous work will be moved toward maturity. OUTCOME partners include Aernnova (Miñano, Spain) and Spanish aeronautical centers Tecnalia (Derio), CATEC (Seville) and CTA (Aeronautical Technologies Centre, Miñano). ADS is the OUTCOME work activities leader.

Although automated methods for laying thermoplastic prepreg are certainly proven technology, they are not yet ready for large primary structure, so a lot is at stake. “Current thermoplastic methods require forming equipment, presses — often an autoclave,” Rodriguez explains, referring to the practice by others of briefly autoclaving thermoplastic parts to boost consolidation and reduce porosity to <2%, which “requires high capital and energy costs, with a typical focus on smaller parts. We are developing a completely out-of-autoclave process, while maintaining good properties, for large parts.” The opportunity for one-step production, he says, involves gas torch, infrared or laser heating of the material, and integration of structure by co-consolidation — that is, melt-fusing the skin and stringers in one step.

In the ISINTHER project, a co-consolidated thermoplastic demonstrator panel was produced in three distinct stages:

- Stiffener laminate blank layup, with plies consolidated by the MTorres automated fiber placement (AFP) laser- heated head;

- Thermoforming of the stiffeners using a press; and

- Flat and curved skin panel layup over the formed stringer feet, with panel manufacturing and stringer integration in one step (in-situ consolidation).

Necessary to the project was the MTorres AFP head, installed six years ago at the FIDAMC facility on a gantry machine, equipped to melt, deposit and freeze the unidirectional thermoplastic slit tape on a flat or mandrel tool. Its heat source is a 500W Nd-YAG (neodymium-doped yttrium aluminum garnet), variable optic diode laser, capable of continuous and consistent heating of the prepreg to 400°C, the temperature necessary to melt high-performance thermoplastics. A scanner optimally distributes the laser energy between the incoming tape and the substrate. A conformable consolidation roller applies sufficient force to the heated prepreg to achieve co-melting and consolidation. The MTorres AFP head employs the company’s patented rotary cut-and-add on the fly, for rapid laydown without stopping for cuts.

When the machine was installed, it had a single roller to apply pressure in the melting zone, but a second roller was added for additional consolidation during the cooling or freezing phase, when the material crystallizes. Rodriguez recalls that several roller materials were tried. The best solution was two rubber rollers.

He adds, “The critical issue during consolidation is to maintain the temperature long enough to get proper heat transfer through the entire laminate.” That led to several machine modifications over the course of the previous projects. The final change was the addition of a second laser, between the two rollers, which enabled modification of the cooling rate and, consequently, the degree of crystallization, to achieve the best material properties.

The head also is equipped for process monitoring: it features an infrared camera and a pyrometer to record application temperatures and track thermal history during processing. It also records laydown speeds.

For the ISINTHER project, stringers were made first by laying up, on a flat metal tool, 6.2-mm wide AS4/APC2 carbon fiber/polyetheretherketone (PEEK) thermoplastic unidirectional slit tapes supplied by Cytec Solvay (Brussels, Belgium). The layup sequence (0°/90°/+45°/-45°), created a blank with a nominal thickness of 2.1 mm. Blanks were placed between two plates in a press shuttle equipped with infrared lamps, heated to 400°C (with thermocouple control) then quickly shuttled into the press for a 5-minute forming cycle. Omega-shaped (or hat-shaped) stringers were chosen to simulate typical fuselage structure; T-shaped stiffeners also were formed, but in an autoclave process.

Troubleshooting the methodology

“The manufacturing of the stringers using the thermoforming press involved solving several issues, including working temperature, time, heating rate, transfer time when the laminate is melted and the cooling rate,” Rodriguez explains. The legacy AS4/APC2 thermoplastic prepreg material, required by Airbus for the project, presented some challenges, including variations in fiber wetout and tape thickness. To achieve very low void content with the in-situ methods used in the project, he explains, the tape must have a uniform fiber/resin distribution. (Going forward, more tapes, impregnated with PEKK and PAEK polymers, from a proprietary list of suppliers, will be tested as part of the current OUTCOME project.)

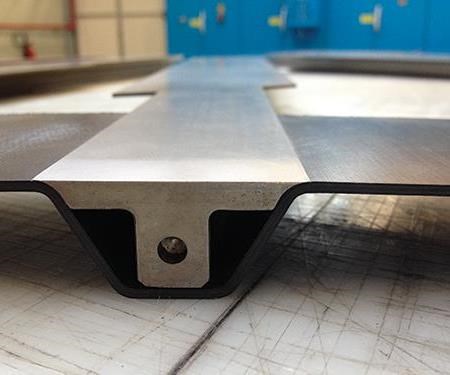

FIDAMC developed a custom, internally heated steel layup tool, 800 mm by 600 mm, consisting of a flat table-like surface with a 10-mm deep, 100-mm wide and 800-mm long central longitudinal countersunk “valley” or recess, and underlying support structure. Into the recess, a formed carbon fiber/PEEK stringer could be placed upside-down, with its flat flanges positioned flush with the flat tool surface. Says Rodriguez, “The tooling allows us to place a consolidated thermoplastic within the hollow, and lay up the skin above it with the automated machine.” The thermoplastic skin would be deposited by the laser-heated head in a quasi-isotropic layup sequence at the same nominal thickness as the stringers.

Initially, however, this, too, posed challenges: Because the PEEK material has no tack, it would not adhere to the tool. “We had to add a vacuum system to the layup tool, to help hold the first ply down,” explains Rodriguez. “Then the stringer flanges were difficult to melt and adhere to the skin’s first ply. We tested several surface treatments for the stringer flanges, including several types of peel ply.” The peel ply wasn’t effective, so ultimately, manual sanding with a fine-grit abrasive was used to prepare the flanges to co-melt with the skin layup.

The ISINTHER project ultimately produced a 600-mm by 800-mm, full-scale demonstrator panel with two, co-consolidated straight omega stringers, as well as a cockpit frame stiffener with shorter stringers. The final parts were molded in a second, modular tool designed to accommodate stringers of different sizes and shapes by swapping out interchangeable modules made to a variety of recess sizes and configurations. Says Rodriguez, “With the modular tool, we can manufacture stiffened panels with two types of omegas and even another type of geometry, say a stiffener with a joggle. All that needs to be changed would be the stiffener modules.”

FIDAMC has documented its process parameters and conducted extensive testing of the final carbon fiber/PEEK laminates, as correlated with real-time process monitoring. Standard In-plane Shear Strength (IPSS) tests, performed in accordance with ASTM D 3846 methods, were used to assess part degree of consolidation (DOC), and compared to autoclaved samples, because “shear strength is the dominating factor in the matrix- interface performance,” says Rodriguez. The data show that parts have 35-45% crystallinity in the matrix and require no further post-cure nor vacuum bag/autoclave processing. Coupon tests show complete co-melting and material continuity between skin and stringers. A design allowables database also has been developed. “We’ve got a mature and robust co-consolidation manufacturing process, validated through a real aircraft stiffened frame, with acceptable porosity,” he says. “The knowledge achieved with those activities will be used in the recently launched Clean Sky 2 OUTCOME project.”

Industrializing the process

Clean Sky 2 OUTCOME is, in fact, underway. FIDAMC and its partners want to improve and scale up the process, produce a larger stiffened wingskin panel, incorporate it into the wing of a CS2 regional aircraft, and flight test it in 2020. Several additional items are on the group’s agenda, among them continued improvement in layup productivity (wider tapes or more tapes layed, simultaneously). Also, an eight-tow head will be incorporated into the existing MTorres machine, along with new advances in laser optics. The technology improvements will be used to produce parts with more complex geometries. Different stringer styles also will be produced, using rollforming and even autoclave consolidation methods. Improved surface treatment for bonding of the stringer feet to the skin, including plasma, will be investigated.

Lastly, the group will expand on repair strategies that it has already researched. The manufacturing trials have demonstrated the feasibility of in-situ repairs that might be extra polated for in-service use through the development of a reliable blanket heating system with a portable repair technology. “It would be interesting to study other bonding technologies for in-service repairs, with local heating systems and fusion bonding techniques, bulk heating or adhesive bonding,” says Rodriguez.

OUTCOME’s goal is to achieve technology readiness level [TRL] 6 for the in-situ thermoplastic layup process. Concludes Rodriguez, “Thermoplastics offer damage tolerance, chemical resistance, infinite shop life, weldability, ability to recycle and shorter manufacturing cycles compared to thermosets. Not only are material properties high, but there is potential for faster processing, lower lifecycle costs and environmental sustainability.”

Related Content

Recycling end-of-life composite parts: New methods, markets

From infrastructure solutions to consumer products, Polish recycler Anmet and Netherlands-based researchers are developing new methods for repurposing wind turbine blades and other composite parts.

Read MoreCirculinQ: Glass fiber, recycled plastic turn paving into climate solutions

Durable, modular paving system from recycled composite filters, collects, infiltrates stormwater to reduce flooding and recharge local aquifers.

Read MoreMicrowave heating for more sustainable carbon fiber

Skeptics say it won’t work — Osaka-based Microwave Chemical Co. says it already has — and continues to advance its simulation-based technology to slash energy use and emissions in manufacturing.

Read MoreRecycling hydrogen tanks to produce automotive structural components

Voith Composites and partners develop recycling solutions for hydrogen storage tanks and manufacturing methods to produce automotive parts from the recycled materials.

Read MoreRead Next

Thermoplastic composites: Primary structure?

Yes, advanced forms are in development, but has the technology progressed enough to make the business case?

Read MoreThermoplastic composites technology: A view from Europe

For this Dutch consortium, bringing the manufacturability of thermoplastic materials to maturity is the goal in concert with OEMs, materials and equipment supplier members.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read More