.jpg;maxWidth=250;quality=70)

Peggy Malnati MMT, Contributing Writer

IACMI SMC Workshop: From What to Why

Introductory course teaches students about composition, characteristics, benefits of sheet-molding compound.

Read MoreHigh-speed, high-rate thermoplastic composites manufacturing

A novel process from SABIC and Airborne promises high-speed, high-rate production of thermoplastic composite laminates for mainstream manufacturing and a variety of applications.

Read MoreEvolving into continuous fiber reinforcements

SABIC expanded its materials offerings in short-fiber injection and long-fiber thermoplastic (LFT) materials to include continuous-fiber thermoplastic tapes.

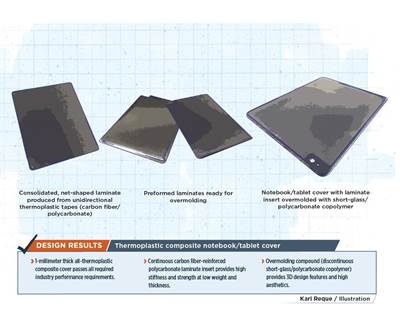

Read MoreConsumer electronics: hybrid composite covers

Study demonstrates feasibility of thermoplastic composites, high-speed production process.

Read MoreComposites-focused engineering, simulation services company launches in Germany

Simutence GmbH, a company started by Karlsruhe Institute of Technology graduates, offers custom simulation methods to composites manufacturers across end markets.

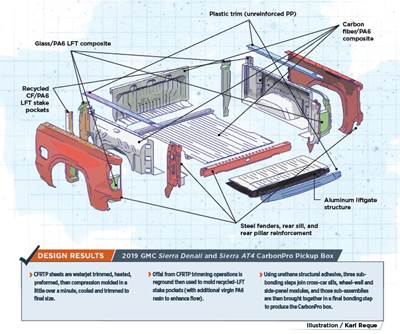

Read MoreDiscriminating features of the 2019 Sierra Denali

Alongside the carbon fiber composite CarbonPro pickup box, GMC’s Sierra Denali pickups offer an array of other game-changing and customizable features.

Read MoreAuto industry explores engineering thermoplastic performance improvements

Polyamides, carbon fiber prominent at 2019 SPE AutoEPCON.

Read MoreSereebo CFRTP sheets: "Saving the Earth"

Teijin’s carbon fiber/thermoplastic material, used in the CarbonPro pickup box, was developed with CO2 reduction in mind.

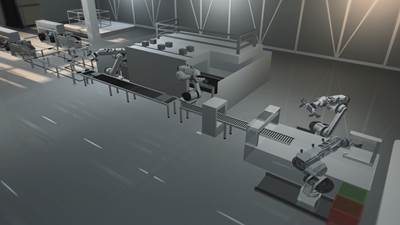

Read MoreCarbonPro box: new forming process

From materials to assembly, the carbon fiber composite CarbonPro box manufacturing process features innovative, automated preforming technologies.

Read MoreSplit tow carbon fiber boosts SMC performance

Pre-spread, pre-scored tow band provides better fiber dispersion, wetout, molding properties.

Read MoreChopped carbon fiber, polyamide and innovation redefine the modern pickup truck bed

CarbonPro, the first thermoplastic composite box, boosts damage resistance, reduces mass 28 kg, scales to high production volumes.

WatchHybrid resin system: Epoxy benefits, without the epoxy

Rapid cure, zero tack material ideal for automated, higher-volume production.

Read More