.jpg;maxWidth=250;quality=70)

Peggy Malnati MMT, Contributing Writer

SMC: Old dog, new tricks

A sheet molding compound renaissance highlights new reinforcements, new fillers, new matrices, new opportunities.

Read MoreThermoplastic composites: Occupant protection in transportation

European consortium develops, validates unique hybrid process for a glass/PA6 engine-compartment bulkhead to replace stamped steel on commercial trucks.

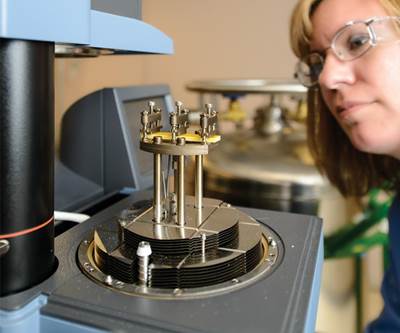

Read MoreMachine vision: Rapid error detection

Aerospace-aimed ply placement technology evolves into process management and near-real time inspection system for production laminated composite parts.

Read MoreBreathing-mold process yields sandwich composite from LFT

In-cavity foaming and controlled mold-opening technique creates core and faceskins from a single injection molded material, reducing part mass and boosting performance.

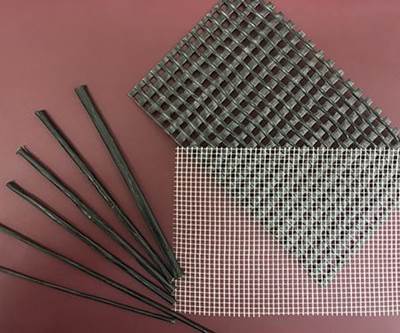

Read MoreSelective reinforcements boost “commodity” composite properties

Strategically placed advanced reinforcements reduce weight, cost while dramatically increasing mechanical performance and dimensional stability.

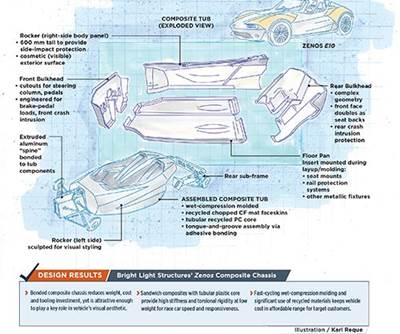

Read MoreForm + function = Classy chassis

Sandwich-composite chassis components double as structural and styling elements, reducing cost of ownership.

Read MoreLower cost, less waste: Inline prepreg production

New technologies move direct (fabricator-based) prepregging closer to reality.

Read MoreThermoplastic honeycomb cores: Tough insulated sandwiches

Foam-filled nylon/polyester fabric yields sandwich panel cores with excellent mechanicals, durability, thermal insulation.

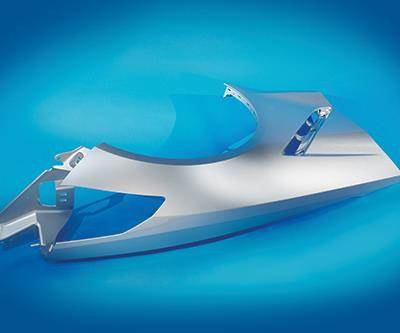

Read MoreLow-density SMC: Better living through chemistry

Proprietary sizing, special glass roving and microspheres strip 9 kilos of weight from Corvette body panels.

Read MoreComposite rebar strengthens riverbed “catfish houses”

Basalt-reinforced polyester rebar eliminates rust and spalling and extends the useful life of concrete catfish spawning and habitat units in Chicago River environmental restoration effort.

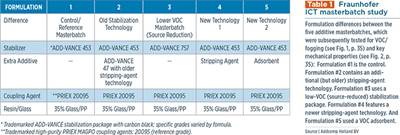

Read MoreVOC reduction strategies for LFRT composites

Additives supplier seeks novel methods to limit VOC emissions from long-fiber-reinforced thermoplastics.

Read MoreRapid tooling breakthrough: Fused particle technology

Super-fast, inexpensive tooling is ideal for low-pressure molding processes and low production volumes.

Read More