Thermoplastic composite B-pillar?

The University of Delaware-Center for Composite Materials worked with several partners, including BMW, to develop a carbon fiber/thermoplastic composite automotive B-pillar that meets structural and crash safety requirements. Next stop, production?

Share

Read Next

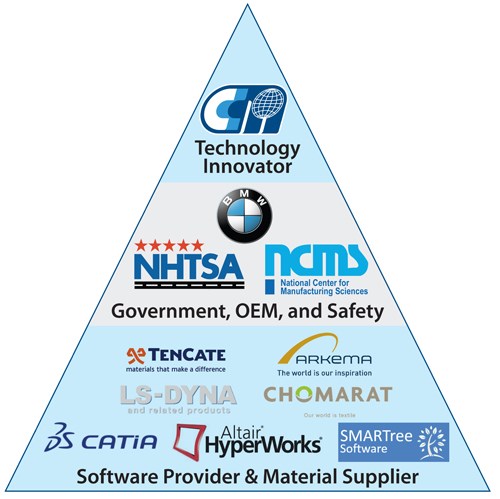

The University of Delaware-Center for Composite Materials (UD-CCM) worked with the National Center for Manufacturing Sciences, the National Highway Transportation Safety Administration and BMW to provide the viability of a thermoplastic composite automotive B-pillar.

The University of Delaware-Center for Composite Materials (UD-CCM, Newark, DE, US), in partnership with the National Center for Manufacturing Sciences (NCMS), the US National Highway Transportation Safety Administration (NHTSA) and automaker BMW, investigated thermoplastic carbon fiber reinforced materials for vehicle sideframe structures.

The proposed B-pillar was designed to meet structural and crash safety requirements (e.g., FMVSS 214 barrier) using thermoplastic composites, which offer significant advantages (e.g., recycling, joining, >60% elongation leading to improved ductility and energy absorption) compared to thermoset composites, with the potential for improved crash performance. Novel side-impact crash concepts maximizing crash performance have been developed and commercially available thermoplastic materials were characterized to define appropriate material models and to evaluate energy absorption mechanisms.

The B-pillar, fabricated using carbon fiber in an infusion and thermoforming of tailored blanks, was optimized for energy absorption, stiffness and strength.

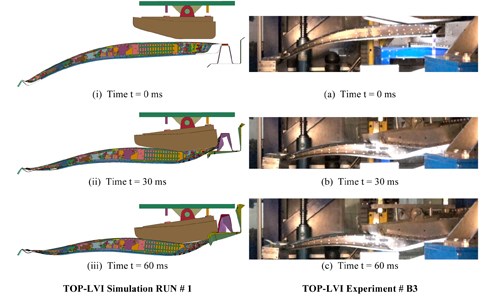

UD-CCM says predictive engineering at all levels, from coupon to sub-element to full-scale, guided the material down-selection. The same CAE tools simulate full vehicle to component and test setup behavior and were used to optimize manufacturability and structural/crash performance. Sub-components and B-pillars have been fabricated using the stamp forming and infusion processes, allowing scalability with the potential to meet automotive production rates. UD-CCM’s large drop tower was used to validate the predictive engineering tools and crash performance of the proposed B-pillars under realistic side-impact crash conditions.

The B-pillar design was spatially optimized for energy absorption (ductility), stiffness and strength, while maintaining part producibility and vehicle integration. BMW established B-pillar performance metrics derived from full-vehicle crash simulations and other design and integration requirements. UD-CCM provided a full range of capabilities in materials selection and evaluation, composite design, analysis and crash simulations, process development and manufacturing (tooling, part production, trimming), full-scale pillar assembly and high-energy impact testing. This project has demonstrated design, materials, manufacturing and joining methods with continuous carbon fiber thermoplastics, at technology readiness level (TRL) 4-7 to meet automotive industry and government safety specifications.

UD-CCM says key achievements from the project include:

- Successful fabrication and manufacture of an all-thermoplastic composite B-pillar that is 60% lighter than the existing metallic design while meeting project requirements for NHTSA FMVSS 214 side-impact crash

- State-of-the-art CAE tools were evaluated (with internally developed data translation) simulating full vehicle to component impact (Dassault Systemes CATIA, Altair HyperWorks & LSTC LS-DYNA)

- Innovative production methods were developed and demonstrated for this multi-material part that included infusion and thermoforming tailored blanks, with the potential to meet 2-minute cycle times

- Adhesive bonding methods were developed and automated for dissimilar thermoplastics and steel interfaces

- Automated trimming of the thermoplastic components was developed and demonstrated without damage to the composite structure

- A test fixture was designed and integrated into UD-CCM’s high-energy impact tower, simulating the crash behavior during side-impact crash without using a full vehicle structure

- Multiple full-scale B-pillar assemblies (incorporating steel roof and frame rail) were successfully impact tested under 100% equivalent energy of FMVSS 214

- The composite B-pillar's response in the vehicle sub-component configuration satisfies all of the intrusion safety requirements

- All-composite B-pillars exhibited rebound and post-impact structural integrity, fully supporting the impactor dead weight of 568.80 kg

- The impact test was simulated and compared to the experimental data (deflection, load and others), validating the predictive engineering approach

- Continuous carbon fiber thermoplastic composites are shown to exhibit improved ductility and energy absorption

Partners in the thermoplastic B-pillar project.

UD-CCM says this effort has demonstrated design, materials, manufacturing and joining methods with continuous carbon fiber thermoplastics at TRL 4-7 to meet automotive industry and government safety specifications. Results of this program will be disseminated widely to the automotive industry and the technologies are being evaluated by BMW for future platforms.

Related Content

The state of recycled carbon fiber

As the need for carbon fiber rises, can recycling fill the gap?

Read MorePlant tour: Middle River Aerostructure Systems, Baltimore, Md., U.S.

The historic Martin Aircraft factory is advancing digitized automation for more sustainable production of composite aerostructures.

Read MoreBio-based acrylonitrile for carbon fiber manufacture

The quest for a sustainable source of acrylonitrile for carbon fiber manufacture has made the leap from the lab to the market.

Read MoreNovel composite technology replaces welded joints in tubular structures

The Tree Composites TC-joint replaces traditional welding in jacket foundations for offshore wind turbine generator applications, advancing the world’s quest for fast, sustainable energy deployment.

Read MoreRead Next

The next-generation single-aisle: Implications for the composites industry

While the world continues to wait for new single-aisle program announcements from Airbus and Boeing, it’s clear composites will play a role in their fabrication. But in what ways, and what capacity?

Read MorePlant tour: Teijin Carbon America Inc., Greenwood, S.C., U.S.

In 2018, Teijin broke ground on a facility that is reportedly the largest capacity carbon fiber line currently in existence. The line has been fully functional for nearly two years and has plenty of room for expansion.

Read MoreCombining multifunctional thermoplastic composites, additive manufacturing for next-gen airframe structures

The DOMMINIO project combines AFP with 3D printed gyroid cores, embedded SHM sensors and smart materials for induction-driven disassembly of parts at end of life.

Read More

.jpg;maxWidth=300;quality=90)