Demonstrator project targets circularity solutions in carbon fiber composite sports equipment

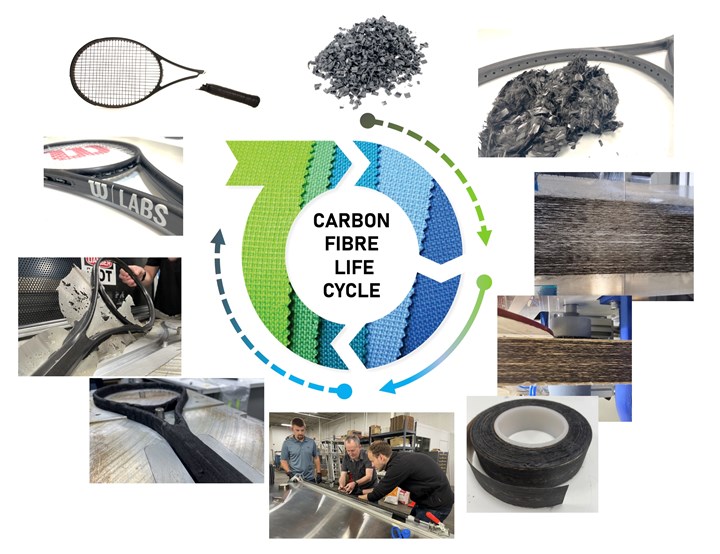

The Carbon Fibre Circular Alliance (CFCA) brought together OEMs and technical partners to reclaim short carbon fibers from end-of-life sports equipment, realign into continuous prepreg tapes and remanufacture into new equipment.

Share

Circularity in carbon fiber sports equipment. Aiming to create circularity solutions for hard-to-recycle carbon fiber sporting goods equipment, the World Sailing Trust created a collaborative initiative called the Carbon Fibre Circular Alliance (CFCA), which combines sports federations, sporting goods OEMs and recycling specialists to demonstrate ways to remanufacture end-of-life (EOL) equipment into new parts. Photo Credit: Lineat Composites

Design for recyclability and use of recycled materials to manufacture sports equipment are gaining momentum, driven by legislation in some regions, changing federation rules in some sports and globally propelled by customer demand.

Andrew Goodman, CSR/sustainability manager at sporting goods manufacturer Scott Sports (Givisiez, Switzerland), says retailers and customers are increasingly demanding the use of sustainable materials. “We’re seeing it become more and more of a normal process for us to integrate eco-responsible materials into our products.”

“Taking care of the planet is one of our main focus areas,” says Victoria Low, head of the World Sailing Trust (London, U.K.), the charity arm of international sailing federation World Sailing (London). This focus has led to seeking solutions both for the materials used to manufacture sporting goods and how to responsibly recycle or repurpose equipment at its end of life (EOL). “For example, World Sailing will require that manufacturers’ non-reusable or non-recyclable boatbuilding waste does not exceed 20% of the boat hull’s finished weight across World Sailing Classes by 2030.”

In this case, for elite sporting goods such as those used in the Olympics, recyclability of carbon fiber composites becomes a major focus. “Eighty-five percent of winter Olympic sports, and 50% of summer sports, use carbon fiber,” Low says. “In addition [for sailing], new class bids for the 2032 Olympics (and subsequent Olympics) need to provide a lifecycle assessment [LCA] that demonstrates that 90% of the boat (by weight) is recyclable.”

In early 2022, the World Sailing Trust began a new collaborative initiative called the Carbon Fibre Circular Alliance (CFCA), with the goals of expanding awareness and creating solutions for carbon fiber composite recycling and circularity within sectors of the sporting goods industry. Headed by the World Sailing Trust, the CFCA is made up of four additional sports federations — the International Tennis Federation (London, U.K.), the International Biathlon Union (Salzburg, Austria), the Union Cycliste Internationale (UCI, Aigle, Switzerland) and World Sailing — and sporting goods equipment manufacturers Wilson Sporting Goods (Chicago, Ill., U.S.), Scott Sports, Starboard (Bangkok, Thailand) and One Way Sport (Vantaa, Finland).

Beginning in April 2022, the CFCA organized and funded its first research demonstration project. The goal of this first initiative was to create a fully circular solution: each sporting goods OEM would provide carbon fiber composite equipment, from which carbon fibers would be reclaimed, reprocessed into usable materials and then remanufactured into new equipment.

To make this happen, the CFCA partnered with Lineat Composites (Bristol, U.K.), a company that has developed technology for realigning discontinuous carbon fibers — specifically, those reclaimed from manufacturing scrap or EOL parts — into new, continuous-length, unidirectional (UD) tapes with highly aligned short fibers.

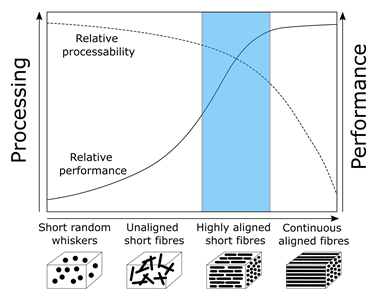

Lineat Composites’ realigned fiber tape technology

Lineat Composites began as a research program called HiPerDiF (High Performance Discontinuous Fibre), which ran from 2017-2020 led by researchers at the University of Bristol. The goal was to develop a process for consistently aligning discontinuous carbon fibers and making them into unidirectional (UD) prepreg tapes. Aligning discontinuous fibers in this way is not a new concept, and several companies have developed related processes and launched realigned fiber products over the years. The potential advantages to this type of product include lower material costs compared to continuous carbon fiber tapes while maintaining the same high performance, and solving wrinkling issues during complex layups, as discontinuous fibers have more freedom of movement than continuous fibers do and can conform more easily over complex geometries.

The HiPerDiF researchers specifically aimed to develop an inline, highly automated process for realigned fiber tapes consistently at higher volumes. Eventually, the project also evolved to focus not only on realigning discontinuous fibers, but also recycled fibers.

The method that was developed involves what Lourens Blok, CTO and co-founder of Lineat Composites, explains as a “hydrodynamic aligning method.” Essentially, it is a three-step process:

- Discontinuous fibers are suspended in water.

- These fibers are then sprayed through an alignment head between two parallel plates. A change in momentum as the fibers strike the back plate causes them to rotate and align between the plates, after which they drop down to a mesh conveyor belt and onto backing films to create aligned tape preforms.

- The preforms are dried using infrared heating, then are combined with a polymer film tape under heat and pressure.

Lineat claims its process can retain up to 85% of the mechanical properties of an equivalent continuous fiber.

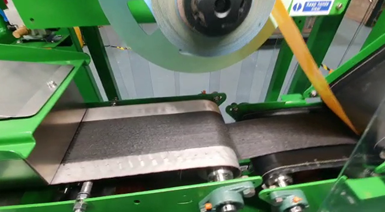

The Lineat process. Lineat designed its alignment technology as a solution for processing carbon fiber scraps or EOL parts into new unidirectional tapes. Photo Credit: Lineat Composites

Following the success of the initial HiPerDiF research and multiple published papers, Lineat Composites spun off from the University of Bristol as its own company in 2021 to scale up and commercialize this technology. Gary Owen, CEO of Lineat Composites, says, “In the end, there were still a lot of manual steps in the HiPerDif process, which we’ve now automated. It’s taken us a couple of years but we’ve been able to successfully optimize the process for scale.”

This has included the development of a commercial-scale fiber alignment system capable of producing 100-millimeter-wide tapes (with wider tapes in development), at a production speed of up to 1.8 meters/minute — to produce about 2 metric tonnes of prepreg per year. To support commercial production on this system, the company plans to move into a new facility in 2024.

Realigned tapes. Lineat Composites’ commercial realigned process (part of the machine is shown in the top photo) will first be used to release a line of epoxy prepreg tapes (bottom image), followed by dry fiber fabrics and thermoplastic tapes that are currently in development. Photo Credit: Lineat Composites

System improvements include an automatic feeder system and an automatic fiber dispersion system, as well as other improvements to the dispersion process “to improve alignment, quality and to reduce defects in the material,” Blok says.

What materials can be processed? In general, Blok says the process is material-agnostic — realigned tapes have been created using a variety of synthetic and natural fibers, including reclaimed fibers recovered using a variety of recycling methods. Lineat has worked with a variety of synthetic and bio-based thermoset resins while also working toward production of dry fiber fabrics and thermoplastic tapes. Owen notes, “There’s quite a bit of work that goes into analyzing the different feedstocks before we actually put them into the process.” As a first step, the initial commercial line is set up to realign standard modulus carbon fibers reclaimed from manufacturing scrap and then prepreg these with epoxy film.

Balancing processability and performance. While serving as a solution for repurposing reclaimed fibers, aligning short fibers can also help ease drapability and wrinkling issues that can occur when trying to lay up continuous fiber prepreg over complex curves. The spaces between the discontinuous fibers enable more freedom of movement around curves. Photo Credit: Lineat Composites

How do the tapes perform? “The performance of the tape depends on three main factors: Fiber type, alignment and FVF [fiber volume fraction],” explains Blok. “Similar to normal fiber composites, the fiber is the driving factor for strength and stiffness, which can vary depending on how the fiber is reclaimed. And the level of fiber alignment and FVF are closely related, which depend on how well the feedstock fiber processes such that a FVF of 40% or higher can be reached.” Lineat is currently selecting a preferred fiber type for which it will make the performance data available when the first products are launched.

Lineat Composites plans to launch its first commercial product in Q1 2024, starting with 100-meter rolls of 100-millimeter-wide epoxy prepreg tape. The standard product uses SHD epoxy (following a collaboration with resin supplier SHD Composite Materials Ltd. (Sleafod, U.K.) signed in 2023) and a standard modulus carbon fiber with resin content percentage of 50% by weight.

After this initial rollout, the second product will be a dry fiber fabric, with additional materials in early stages of development.

“We’re optimizing the process and scaling up over the next couple of years to industrial scale, while also being realistic with the supply that we have,” Owen says. “We’re working across all sectors, including aerospace, automotive and sporting goods.”

Blok adds, “There is a lot of interest in custom circular recycling projects from companies, but there is also a huge opportunity to use existing chopped fiber waste currently destined for landfill, that is easier to process at scale. This is an alternative to virgin carbon fiber, has better traceability and has essentially a zero carbon footprint as it is saved from landfill.”

Alongside these commercialization efforts, Lineat is also still engaging in R&D initiatives, such as the CFCA demonstrator project. “We connected with the CFCA because my background is originally in the marine industry, so I was familiar with the World Sailing Trust, and we also had connections in the sporting goods market with Wilson and others, through research that Lourens had done,” Owen explains.

The demonstration project would be one of Lineat’s first opportunities to test out its technology with real-world applications. While sporting goods is only one end market that Lineat is targeting, “when you’re talking about the sports sector, there’s a desire to be more sustainable, and if they can use recycled materials to make new products, that’s a great opportunity there,” Owens says.

Blok adds, “We were excited to get involved and to speak with new manufacturers through this project, because it’s through initiatives like these that we can learn how to truly establish a composites recycling supply chain.”

The CFCA demonstration project

In spring 2022, each of the four participating OEMs contributed pieces of equipment — tennis rackets from Wilson, bicycle frames from Scott Sports, cross-country ski poles by One Way and paddle board blades from Starboard.

Scott Sports’ Goodman says, “We were invited by UCI to represent our bike brand specifically. One of the interesting things for us as a company is that we have quite a wide variety of products, like bicycle components, skis, ski poles and more, so this gives us a bit of flexibility in order to see what application is best to put a new material into, depending on its maturity.”

The Lineat Composites team manually broke down the received components into 6-millimeter pieces, and then were sent to recycling partner Longworth (Blackburn, U.K.). Lineat originally began working with Longworth in 2020, as part of a U.K. government-funded initiative called Sustainable Composites.

Longworth’s fiber reclamation process, branded as DEECOM and called a “pressolysis” process, uses controlled cycles of pressurized, superheated steam to separate fibers and resin to result in reclaimed fibers retaining high mechanical performance. A commercial version of the DEECOM system was launched at JEC World 2022 by partner Cygnet Texkimp (Northwich, U.K.).

For the CFCA project, Lineat Composites worked with Longworth to determine the optimum processing temperature and conditions for reclaiming fibers with the highest quality. “Our contacts at the University of Bristol performed a series of thermal gravimetric tests that allows us to find the sweet spots at the operating temperature for the DEECOM process, which we sent back to Longworth,” Blok says.

From bicycle frames to skis. Scott Sports used the realigned tapes manufactured from its original carbon fiber composite bicycle frames within a set of prototype skis. The company continues its research efforts with Lineat Composites to develop tapes for use with other products and processes. Photo Credit: Scott Sports

This analysis step is pivotal when working with EOL parts, Blok adds. Lineat’s initial commercial products will be produced from reclaimed fibers from manufacturing scrap, which provides a level of consistency and predictability both in terms of raw material supply and mechanical properties. EOL parts generally require more analysis and processing before recycling, to remove fasteners or chop into smaller pieces before the fiber reclamation step, or to remove sizing or adhesives from the materials themselves. “That’s why it’s important to have the industry talking together, so we can come up with solutions together. That’s part of what the CFCA is about, not only aligning fibers, but aligning people,” Blok says.

Next, the reclaimed fibers were realigned with Lineat’s technology and combined with an aerospace-grade epoxy resin (SHD MTC400-1) in film form to produce 1-inch-wide tapes. According to Blok, the collaboration with SHD allows for the combination of any of their formulations within Lineat’s tapes. Future product iterations will look to combine SHD enhanced systems such as MTB350 or VTB301, which offer extended outlifts and up to 30% bio-based content while providing equivalent performance.

These final prepreg tapes were then sent back to the original manufacturers to explore development of new sporting goods components with these materials. Blok adds, “All components were processed individually. All fibers from tennis rackets were aligned into a tape sent back to Wilson, and the fibers from Scott’s bike frame were sent back to Scott.”

The tapes show promising mechanical properties and enable replacement of virgin fiber, but are not quite a drop-in replacement, Blok notes. The 1-inch tapes produced for this project were narrower and lighter than what many companies would normally use for production components, meaning each of the companies needed to explore new ways of using the material. “The material is similar to continuous fiber prepreg tape but you will need a bit more explanation and little tweaks on how to use the tapes we produce,” Blok explains.

Scott Sports’ Goodman says, “We didn’t so much reuse the tapes in [complete] components as test them to see how they would react, and to see how the material is usable in terms of our normal production. It gave us experience in terms of how to handle the tape, how it works and we were able to have conversations with Lineat about how we can improve the material and process to get closer to the mechanical properties we need.”

By the end of 2022, each of the sporting goods OEMs had the chance to remanufacture test components using the tapes from Lineat. One Way produced new ski poles, Starboard manufactured paddleboard fins, Scott Sports used the tapes to manufacture demonstrator skis and Wilson built a prototype tennis racket using 50% realigned carbon fibers.

Racket redesign. Project partner Wilson Sports’ carbon fiber composite tennis rackets were broken down, the reclaimed fibers realigned into epoxy prepreg tapes and a new tennis racket was made with 50% recycled carbon fiber (rCF). Shown at bottom, Lourens Blok of Lineat Composites (middle) and Mitch Zavesky and Bill Severa of Wilson with the remanufactured racket at Wilson’s Seattle R&D center. Photo Credit: World Sailing Trust

Blok notes, “Wilson Labs came up with a really clever way of laying up the 1-inch-wide material to manufacture a tennis racket. Scott Sports applied the tape made with cabon fibers from a bike frame back into a ski, and Starboard supplied us with broken masts and they used the tape to manufacture a fin.”

“This was the first project where we really put the technology into practice on actual parts,” Blok adds. “Once you get going, you do start to see what the real challenges are and get a better idea of how this process will actually work at scale, and we learned a few things along the way. In the end, it was a success as we proved we can take broken sports components made of carbon fiber, reclaim the fibers, realign them and reuse them to replace virgin material.”

Next steps: Olympics, commercialization

What’s next for the CFCA? Low says, “We’ve got a fantastic group of international federations involved and more who want to get involved, which is really good news. We’re also working with the sustainability team at the International Olympic Committee [IOC], and we’ve set ourselves some ambitious targets.”

Demonstrating at the Olympics. During the 2024 Olympic Games in Paris, CFCA project partner Starboard will exhibit an IQ Foil board (an example is pictured) featuring a carbon fiber foil made with reclaimed and realigned fibers during this project. Photo Credit: World Sailing Trust

For the Paris 2024 Games, CFCA member Starboard is planning to exhibit an IQ Foil board featuring a realigned recycled carbon fiber foil at the sailing venue in Marseille, France.

In future, the CFCA and IOC’s goal is that supplied carbon fiber equipment at the Olympic Games, such as that provided to the refugee team, would be made from realigned or recycled carbon fiber. The CFCA also plans to look at other materials besides carbon fiber in sporting goods equipment, like glass fiber and rubber.

Beyond the original CFCA project in 2022, Lineat Composites continues to work toward commercialization of its technology, and on additional R&D work with several of the sporting goods OEMs involved in this project. Goodman notes that several of the projects ongoing with Scott Sports have shown promising results so far. “It’s going to be pretty good for some of our products, because we’re able to use it in the normal production system, and it shows the material properties we would be looking for.”

“We’ve gotten valuable feedback from the CFCA manufacturers, on how they’re actually using the material, and on what is good about the tape and what needs to be improved,” Blok adds. “And that’s where the CFCA really comes in, to help enable that interaction between material providers and manufacturers and help make effective recycling of carbon fiber happen together.”

Related Content

Plant tour: Albany Engineered Composites, Rochester, N.H., U.S.

Efficient, high-quality, well-controlled composites manufacturing at volume is the mantra for this 3D weaving specialist.

Read MoreThe potential for thermoplastic composite nacelles

Collins Aerospace draws on global team, decades of experience to demonstrate large, curved AFP and welded structures for the next generation of aircraft.

Read MoreBio-based acrylonitrile for carbon fiber manufacture

The quest for a sustainable source of acrylonitrile for carbon fiber manufacture has made the leap from the lab to the market.

Read MoreJeep all-composite roof receivers achieve steel performance at low mass

Ultrashort carbon fiber/PPA replaces steel on rooftop brackets to hold Jeep soft tops, hardtops.

Read MoreRead Next

Going discontinuous, for continuous improvement

The HiPerDiF (High Performance Discontinuous Fibre) project is exploring an alternate way of producing high-performance carbon fiber composites: start with discontinuous, rather than continuous fibers.

Read MoreHigh-performance sustainability and cost-efficiency advance with HiPerDiF

In the latest chapter of the HiPerDiF (High Performance Discontinuous Fibre) story, commercial production is on the near horizon for high-performance composite materials that are both sustainable and formable, leading to simpler, more cost-efficient composites manufacturing.

Read MoreSustainable, inline recycling of carbon fiber

Shocker Composites and R&M International are developing a supply chain for recycled CF with zero knockdown vs. virgin fiber, lower cost and, eventually, lengths delivering structural properties close to continuous fiber.

Read More.jpg;width=70;height=70;mode=crop)

.jpg)