Aerospace

Terma Aerostructures: Grenaa, Denmark

This Danish manufacturer of precision composite aircraft parts and components has emerged as a significant player in fabrication of Lockheed Martin’s F-35 Lightning II.

Read MoreClassic Reflections Coachworks: Tacoma, WA, US

They didn’t invent the wheel, but they take pride in reinventing — via high-quality CFRP and precision manufacturing — newer-model Corvettes with exteriors inspired by iconic Corvette stylings from this classic’s early days.

Read MoreAerocomposites: The move to multifunctionality

Designers envision aircraft components that do more than bear structural loads, but must first confront great complexities to actualize greater functional efficiency.

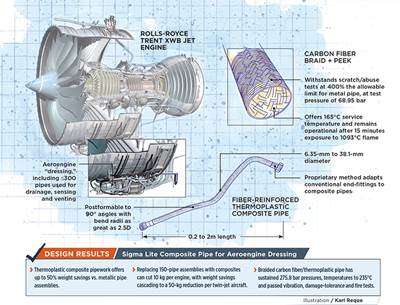

Read MoreRe-dressing aeroengines with composite pipes

Sigma Lite braided carbon fiber/thermoplastic pipe cuts jet engine weight yet meets challenging design and manufacturing requirements.

Read MoreComposite aeroengine dressing to wing driveshafts, SHM and more

For Sigma Precision Components (Hinckley, UK), composite pipe for jet engine dressing could be only the beginning.

Read MoreGE Aviation to build ceramic matrix composite factories

One plant will be the first U.S.-based factory to produce SiC ceramic fiber on a large industrial scale.

Read MoreCW Business Index at 44.6 — Contraction again in September

Steve Kline, Jr., the director of market intelligence for Gardner Business Media Inc. (Cincinnati, OH, US), the publisher of CompositesWorld magazine, reviews the CompositesWorld Business Index through September 2015.

Read MoreIs it time for carbon fiber manufacturers to cooperate?

In anticipation of CompositesWorld's 2015 iteration of its annual Carbon Fiber conference, set for December, CW editor-in-chief Jeff Sloan looks ahead to the future as he recalls some tough questions about carbon fiber standardization posed by last year's keynote speaker.

Read MoreNCDMM, Ingersoll, Orbital ATK complete automated composites inspection system

The Automated Composite Structure Inspection System achieved a defect detection rate of up to 99.7% on aircraft components produced via automated fiber placement.

Read MoreNew 250°F/120°C No Oven No Autoclave epoxy

Designed for room-temp infusion and filament winding with 2-hr no-heat-added cure or 15-30 min heated cure without post-cure for flexible processing of marine, industrial and energy structures.

Read More