Aerospace

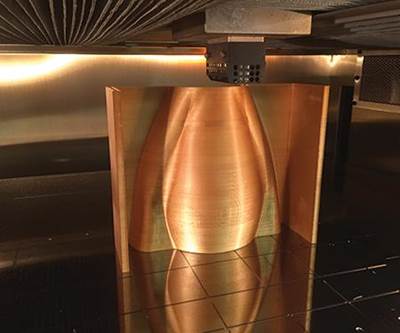

A growing trend: 3D printing of aerospace tooling

Toolmakers and OEMs are embracing additive manufacturing for customized, rapid tools, masters and jigs.

Read MoreWorkforce development: Let's start in high school

CW Editor-in-Chief Jeff Sloan says one concern at the otherwise positive initial membership meeting of the new Institute for Advanced Composites Manufacturing Innovation (IACMI) was that the composites industry is quickly losing knowledge, as old-timers retire, that is not so easily replaced. Here's his prescription.

Read MoreThermosets vs. thermoplastics: Is the battle over?

Dale Brosius, the chief commercialization officer for the Institute for Advanced Composites Manufacturing Innovation (IACMI) and a regular CW columnist, sees a shift in the industry from infighting between proponents of thermoset and thermoplastic composites to a healthier competitive atmosphere that serves to make composites overall more competitive with legacy materials.

Read MoreIndiana Manufacturing Institute breaks ground

The Indiana Manufacturing Institute (IMI) is part of a $50 million project where Purdue University will advance research of composites manufacturing.

Read MoreICON A5 LSA completes FAA compliance audit

The A5 Light Sport amphibian aircraft has received its S-LSA airworthiness certificate from the US Federal Aviation Administration; the first plane will be delivered in July at the EAA AirVenture Oshkosh air show.

Read MoreSummer...time for an air show

Highlights from the 2015 edition of the Paris Air Show, and what to look for at the upcoming EAA AirVenture air show in Oshkosh next month.

Read More3D Printing Moves Into Tooling Components

Some pundits predict that 3D printing, or additive manufacturing (AM), will change our world forever. While that may yet be, one thing is clear: The growth of 3D printing over the past two decades has wrought significant change in composites tooling. Although AM’s most obvious advantage is direct part production without tooling, the growing trend in the aerospace and automotive sectors at present is its use for fast, on-demand builds of mold tools to keep pace with accelerating composite part design cycles and demand for faster overall part processing speeds.

Read MoreDLR researchers develop new repair concept for FRPs

The process uses a laser, induction and a vacuum on damaged areas.

Read MoreTires that never go flat

SciTech Industries and Rapid Composites develop high-volume production tires that use glass fiber/PET composite springs instead of innertubes and compressed air.

Read MoreThermoplastic composites technology: A view from Europe

For this Dutch consortium, bringing the manufacturability of thermoplastic materials to maturity is the goal in concert with OEMs, materials and equipment supplier members.

Read More