Composites 4.0

Cevotec's MAI ACoSaLUS project aims for full automation of composite sandwich structure production

Cevotec works with GKN, TU Munich, SGL Carbon and Augsburg University with an aim to fully automate layup of sandwich parts using FPP, achieve 7-10 times improvement in layup speed.

Read MoreBroetje-Automation delivers EcoPositioners for automated built-in stress-compliant joining in aircraft fuselages

Modularized and highly precise positioning system increases assembly accuracy and speed, enables digitization of CFRP aircraft components assembly for factory of the future.

Read MoreDLR develops concept for final assembly line with artificial intelligence

High-rate production enabled by pre-selection of assembly-ready components, without manual compensation measures, based on neural network training.

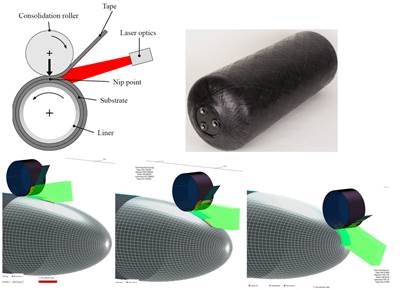

Read MoreOTOMcomposite develops software for Composites 4.0 production using laser-assisted tape placement and winding

Optical thermal optimization model (OTOM) software enables inline monitoring and control for improved part quality and reduced production time and cost of in-situ consolidated thermoplastic composites and Type IV pressure vessels.

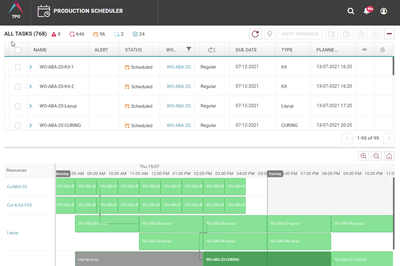

WatchPlataine's new Practicum-Optimum AI algorithm optimizes production scheduling

Self-learning algorithm achieves reportedly unprecedented levels of optimized KPIs and schedule practicalization.

Read MoreBronwyn Fox joins CSIRO agency as new chief scientist

Professor Fox brings 30 years of scientific experience in composites and Industry 4.0 to Australia’s national science agency.

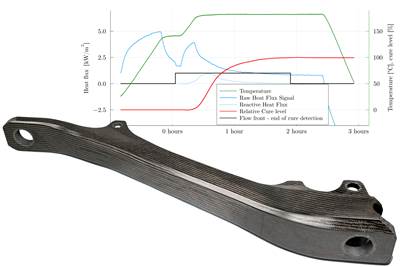

Read MoreSpeeding RTM with heat-flux sensors

Clean Sky 2 INNOTOOL 4.0 project advances cure monitoring for larger and less costly lightweight landing gear made using composites.

Read MoreVDMA Robotics + Automation, GO2automation partnership drives global access to automation

Under the GO2automation platform, small- and medium-sized firms will receive data-driven access to automation and a range of experts, including those in composites production/automation.

Read MoreFill ACCUBOT spurs GKN Aerospace composite aircraft parts inspection

Flexible and precise multimodal robot system conducts quicker inspection processes, reducing GKN’s geometrical inspections from 11 hours to half an hour.

Read MorePlataine, Eastman Machine partnership enhances Industry 4.0 capabilities

Advanced material cutting machine manufacturer to offer customers increased process automation, streamlined production, process traceability and overall efficiency on the production floor.

Read More