Compression Molding

SMC sandwich panels: Lean process opens doors

Patented process enables compression molding at lower pressures, saving capital equipment costs for panel fabrication.

Read MoreRedesigning for simplicity and economy

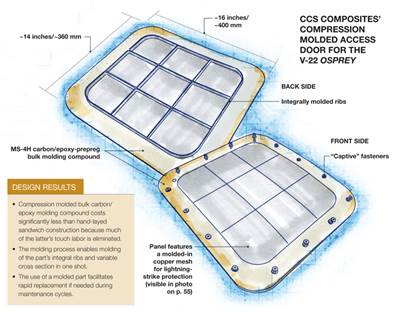

Military OEM makes the switch from sandwich construction to compression molding to optimize composite aerospace part.

Read MoreSPE ACCE 2011: Growing again

The Society of Plastics Engineers’ 11th conference on automotive composites fields a top slate of speakers and attracts its largest crowd.

Read MoreAutomotive composites: Structural underbody

For Detroit’s Big Three, a joint precompetitive composite design, development, fabrication and testing program nears successful completion.

Read MoreCarbon fiber food tray arm: Better and cheaper

CW Conferences director Scott Stephenson summarizes the substance of a presentation at the High Performance Resins 2011 conference (Seot. 27-28) by Mohammad Moniruzzaman (SABIC Innovative Plastics, Pittsfield, Mass.), who detailed the development of a carbon fiber composite food tray arm for passenger aircraft seat backs.

Read MorePress refurbishment a cost-effective strategy for improving production

When a U.S.-based molder of composite friction materials used in aircraft braking systems recently upgraded its factory capabilities, French Oil Mill Machinery Co. (Piqua, Ohio) agreed to rebuild 10 of the molder’s 400-ton presses

Read MoreAn out-of-autoclave progress report

CW Conferences director Scott Stephenson recalls Dale Brosius’ update on Quickstep’s out-of-autoclave work for the F-35 program.

Read MoreSmall wind gets big

Massive growth, complex blade designs reopen challenging market in wind energy niche.

Read MoreHigh-speed press cure for high-speed racers

Trapped tooling and compression molding bring cocuring efficiencies to previously autoclave-cured, aerodynamic fins and planes.

Read MoreSmall wind: Green energy gets greener

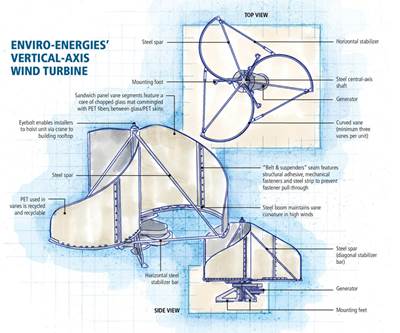

Kilowatt-rated vertical axis wind turbines supply green electric power where utility-scale turbines can’t.

Read More