Compression Molding

Move over steel — Aluminum is now the target

Dale Brosius, a consultant and president of Quickstep Composites (Dayton, Ohio), observes that chasing aluminum as a competitor is a much easier task than chasing steel — if the composites industry can meet cost and volume requirements.

Read MoreBusiness and busy-ness

CT editor-in-chief Jeff Sloan returns for JEC Europe 2014 in Paris with observations about several intriguing composites industry trends.

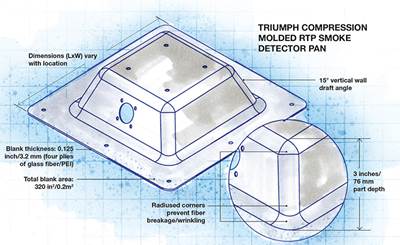

Read MoreCompression molding mass out of aircraft interiors

Continuous carbon fiber-reinforced thermoplastic lightweights smoke detector pan and slashes production cycle time.

Read MoreLFI process: Molding strong and attractive spa enclosures

Dynasty Spas (Athens, Tenn.) finds a composite alternative to wood hot tub surrounds in a polyurethane (PU)-based long fiber injection (LFI) solution implemented by Romeo RIM Inc. (Romeo, Mich.).

Read MoreFaster cycle, better surface: Out of the autoclave

GM is first automaker to use Class A CFRP parts from new pressure-press technology.

Read MorePress-molding method emulates autoclave

Rubber tool insert avoids consolidation pressure “dead zones” and slashes cost.

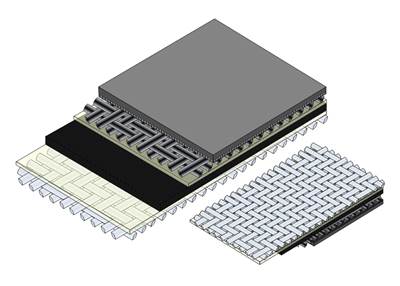

Read MoreClass A CFRP body panels: Six-minute cure

Gurit CBS-based laminate/process combo mints parts with twice the thermal performance in one-sixth the time.

Read MoreFormulation flexibility: Direct-SMC

Consortium applies inline-compounding technology to reinvent sheet molding compound.

Read MoreForging variations

Developed in parallel to the Duqueine Group’s (Massieux, France) MFP process, the high-pressure molding process used by Lentilly, France-based Carbone Forgé is described by Vincent Duqueine as “enabling forging of composites, similar to that done with metals.”

Read MoreForged composites replace complex metal parts

Powerhouse manufacturer’s high-pressure compression molding process forms prepregged CFRP components with forged-metal properties.

Read More