Compression Molding

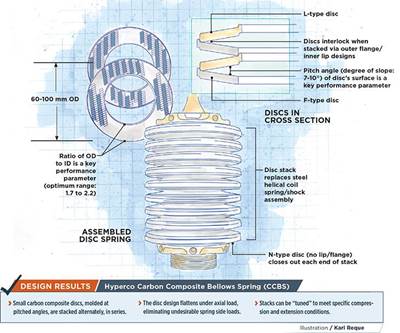

Carbon composite spring: Big performance, small package

Disc spring stack is lighter, reduces friction and can be performance-tuned.

Read MoreComposite engine piston cylinder housings

Phenolic BMC could replace aluminum in car/motorcycle engine housings.

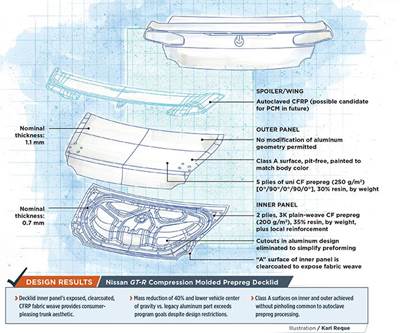

Read MorePrepreg compression molding makes its commercial debut

Ultra-thin, preformed laminate designs enable CFRP decklid manufacture at lower-than-expected mass and at cycle times approaching mass-production speed.

Read MoreThe ends will be justified by the means

CW Editor-in-chief Jeff Sloan recalls the one question he's consistently fielded throughout his quarter century in magazine editing and publishing: “Don’t you worry about running out of things to write about?” Here's his answer.

Read MoreDow: 60-second epoxy is in range with liquid compression molding

Dow Automotive Systems (Horgen, Switzerland) made big news at JEC Europe 2014 with the introduction of VORAFORCE, its ultralow-viscosity, fast-cure epoxy for automotive molding.

Read MoreCobham Composites: San Diego, CA, US

An aerocomposites force since the dawn of the 1980s, this fabricator’s Big Idea is to move from quality control to in-situ process control on the strength of metrics powered by Big Data.

Read MoreLooking for Lindberghs

Every paradigm-shifting invention throughout human history has been met with skepticism. CW editor-in-chief Jeff Sloan says the composites industry has need of those willing to attempt what most believe impossible.

Read MoreIncremental thinking just won’t cut it!

Composites industry consultant and regular CW columnist Dale Brosius says if this industry is to have a future that goes anywhere profitable, then we've got to get off the road we're on and map out a whole new way to think about the tasks at hand.

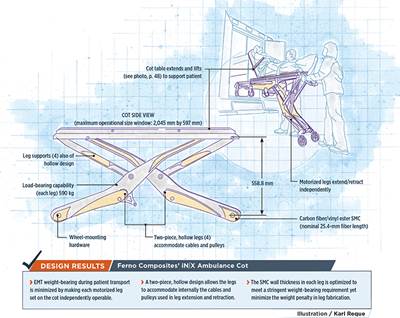

Read MoreManaging weight in emergency medical transport

Repetitive strain risk for first responders sends emergency equipment provider back to the drawing board to develop more ergonomic cot.

Read MoreFabrication methods (2015)

There are numerous methods for fabricating composite components. Selection of a method for a particular part, therefore, will depend on the materials, the part design and end-use or application. Here's a guide to selection.

Read More

.jpg;maxWidth=400;quality=70)