NDI

Composites 4.0: Digital transformation, adaptive production, new paradigms

An evolving landscape of automation, sensors and AI software is not an end, but a means to achieve the cost, quality, efficiency and agility required for future manufacturing.

Read MoreHigh-rate, automated aerospace RTM line delivers next-gen spoilers

At Spirit AeroSystem’s Prestwick facility in Scotland, a glimpse of the future of aerocomposites manufacturing in a resin transfer molding line for A320 spoilers.

Read MoreZAero project update

The 2019 final review demonstrated integration of an automated CFRP process chain: AFP inline inspection and rework, cure and resin flow sensors, part performance prediction and a decision support tool for line operators.

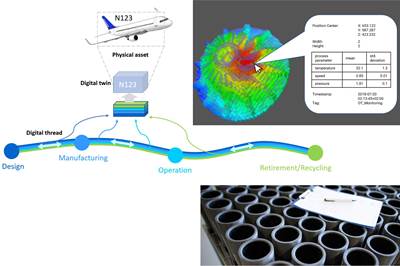

Read MoreDigital thread vs. digital twin

Visualizing the difference between digital representations and data flows and understanding the applications that are changing composites manufacturing and business models.

Read MoreNo business case for reteaching robots

DLR Center for Lightweight Production Technology has developed an AI-equipped work cell where collaborative robots can switch from producing composite rear pressure bulkheads to fuselage panels without requiring reprogramming or retraining.

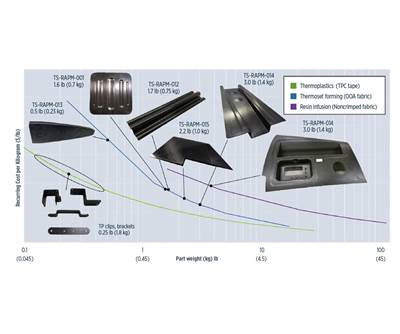

WatchRevolutionizing the composites cost paradigm, Part 2: Forming

Boeing-led parts trials explore infusion, compression molding and thermoplastics, offering lessons and supply chain options to better compete with aluminum.

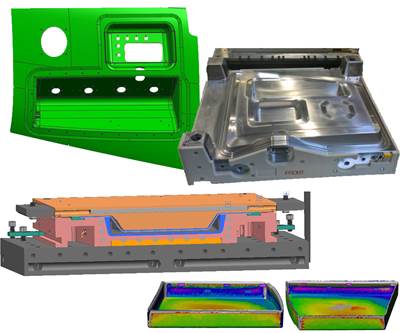

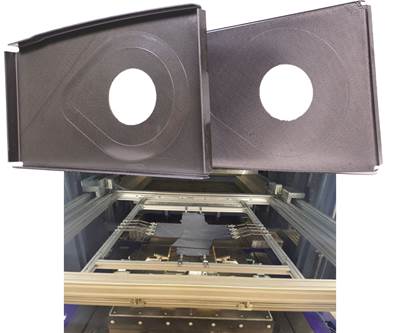

Read MoreManufacturing the complex geometry parts of RAPM

Boeing-led program explores simulation, tooling, preforming and molding approaches to lower composites part cost.

Read MoreNovel prepreg for compression molding in RAPM

Solvay and Boeing combine aerospace performance with process knowledge for high-rate, low-cost composites production.

WatchWelded thermoplastic composite keel beam demonstrator achieved

EURECAT and partner companies complete Clean Sky 2 KEELBEMAN project, demonstrating TRL3 primary structure technology for future aircraft.

Read More