Out of Autoclave

COMPOSITES 2012 Preview

The ACMA’s annual composites industry exhibition focuses on future opportunities.

Read MoreNew catamaran benefits from structural adhesives, vacuum infusion

Vacuum infusion, SAN sandwich foam cores and structural adhesives help reduce the weight of Mattia's high-performance catamaran yacht by 2,000 kg.

Read MoreSAMPE Tech 2011 in Texas

The Society’s annual fall gathering fills an exhibition hall this year nearly as big as the host state.

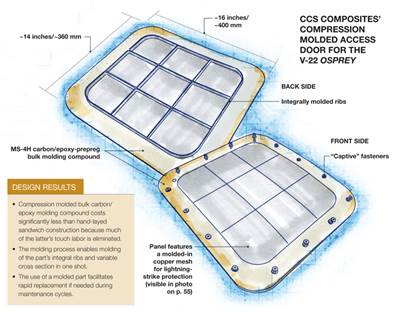

Read MoreRedesigning for simplicity and economy

Military OEM makes the switch from sandwich construction to compression molding to optimize composite aerospace part.

Read MoreAirbus A350 Update: BRaF & FPP

EADS Innovation Works pursues qualification of Braided Frames for the A350-1000 fuselage and develops Fiber Patch Preforming for complex local reinforcements.

Read MoreA hidden revolution: composite rebar gains strength

Fiber-reinforced plastic (FRP) replacing coated steel in more reinforced-concrete applications.

Read MoreSea and land transport: Hydro elevation

Composites lightweight and toughen the hull and superstructure of this transplanted amphibious naval hovercraft.

Read MoreIBEX 2011 Review

As the International BoatBuilders’ Exhibition & Conference again docks in Louisville, the industry continues a slow and tentative rebound.

Read MoreSPE ACCE 2011: Growing again

The Society of Plastics Engineers’ 11th conference on automotive composites fields a top slate of speakers and attracts its largest crowd.

Read MoreAutomotive composites: Structural underbody

For Detroit’s Big Three, a joint precompetitive composite design, development, fabrication and testing program nears successful completion.

Read More