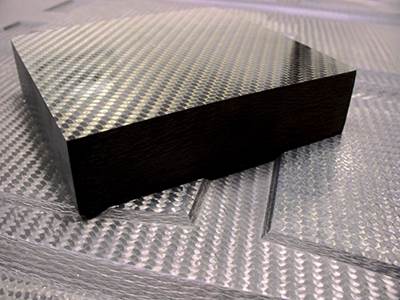

Prepregs

Materials & Processes: Resin matrices for composites

The matrix binds the fiber reinforcement, gives the composite component its shape and determines its surface quality. A composite matrix may be a polymer, ceramic, metal or carbon. Here’s a guide to selection.

Read MoreLufthansa Technik, Diab develop greener composites for interior cabin components

Aeroflax flax fiber-based prepreg and one-step thermoplastic manufacturing process for 100% recyclable panels production pioneer lighter weight, reduce CO2 emissions.

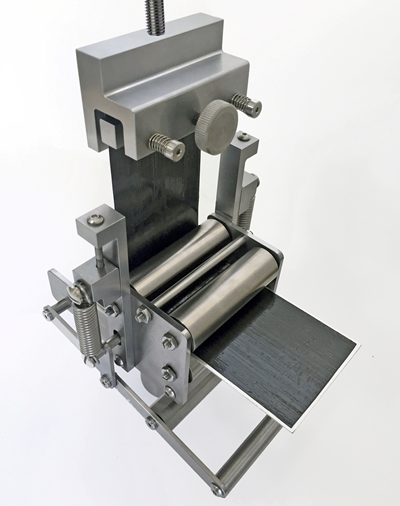

Read MoreComposite prepreg tack testing

A recently standardized prepreg tack test method has been developed for use in material selection, quality control and adjusting cure process parameters for automated layup processes.

Read MoreToray and Bell collaborate on new NCAMP design allowable dataset for 3960 prepreg system

Allowable design dataset establishes conformity requirements and process specifications for traditional hand layup and AFP of the 3960 prepreg system in aerospace applications.

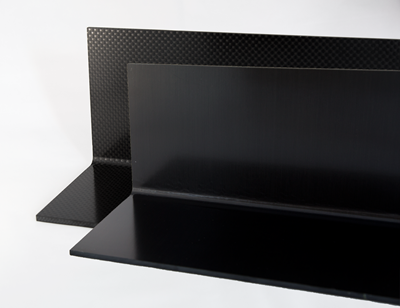

Read MoreHigh-performance sustainability and cost-efficiency advance with HiPerDiF

In the latest chapter of the HiPerDiF (High Performance Discontinuous Fibre) story, commercial production is on the near horizon for high-performance composite materials that are both sustainable and formable, leading to simpler, more cost-efficient composites manufacturing.

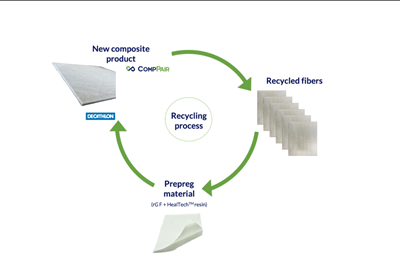

Read MoreCompPair and Decathlon successfully complete composite recycling project

Manufacture of a shoe sole demonstrated the reclamation of continuous fibers with more than 80% of their original flexural strength. Both companies are now seeking additional recycling partners.

Read MoreSuCoHS project: Advancing composite solutions for parts with high thermal and mechanical loads

New materials, structural concepts and manufacturing using sensors for composites that resist fire, temperature and loads while providing weight and cost savings versus metals.

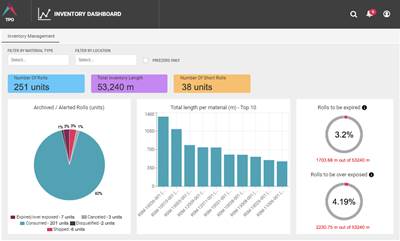

WatchComposites supply chain and production disruptions – how can AI and digitalization help?

Digitizing and creating the factory of the future is a journey, but it has the potential to help composites manufacturers address real-life disruptions and enable fast replanning of production operations for increased flexibility and enterprise-level performance.

Read MoreArcher Aviation plans to work with Hexcel to advance eVTOL production capabilities

Under the proposed relationship, Hexcel will supply its high-performance carbon fiber prepreg material for the production aircraft.

Read MoreHexcel carbon fiber selected for Artemis 9 mission booster production

Lightweight composite design for BOLE boosters enable increased performance for NASA’s future missions to the moon and Mars.

Read More