Processes

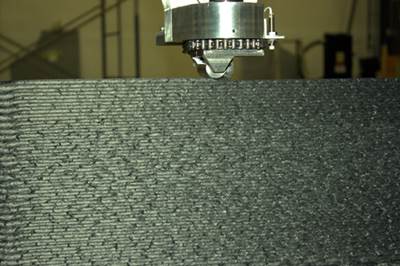

Thermwood developing large-scale additive manufacturing system

The large-format additive manufacturing machine will produce near net shape parts up to 10 by 10 by 5 ft and provide post-process machining and trimming functions as well.

Read MoreNew 250°F/120°C No Oven No Autoclave epoxy

Designed for room-temp infusion and filament winding with 2-hr no-heat-added cure or 15-30 min heated cure without post-cure for flexible processing of marine, industrial and energy structures.

Read MoreInfusion enthusiasm

Although CW didn't attend the EAA AirVenture in Oshkosh in 2015, we did learn about an infusion demo that was the largest ever accomplished at the fly-in event.

Read MoreNew low-cost, high-temp resins

MG Resins offer a suite of properties and processing that could potentially revolutionize sectors of the composites industry.

Read MoreBoat builder Lyman-Morse creates aerospace composite prototype

Prototypes for such clients as the Department of Defense and other government and private sector businesses has become an increasingly important segment of the the company’s business plan.

Read MoreOptimizing composite aerostructures production

Israel Aerospace Industries ramps production while reducing costs and improving quality thanks to integrated optimization software.

Read MoreComposites tackle concussions

The launch of the first commercial composite football helmet and new research thrusts show FRPs could play a critical role in mitigating head injuries.

Read MoreReport from IBEX 2015

As always, IBEX supplied new products, processes and education, not only to boatbuilders, but to the composites industry overall.

Read MoreCFK-Valley Stade Convention 2015 report

The composites industry in Germany is preparing for the 4th Industrial Revolution.

Read MoreSlideshow of SPE ACCE 2015

A look at the 15th edition of SPE’s Automotive Composites Conference & Exhibition (ACCE).

Read More

.jpg;maxWidth=300;quality=90)