Processes

Filament wound pipe proves durable in electric power plants

Korea-based Hankuk Fiber Glass Co. Ltd. develops a much more durable composite alternative to cast iron ash-transfer pipes for coal-burning electric power plant customers.

Read MoreSkinning the F-35 fighter

Fastening the all-composites skin on the Lightning II requires machining and drilling technology that is optimized for cost-efficiency.

Read MoreAutomated solution: New presses for SMC molding process

Using glass/polyester sheet molding compound (SMC) that it formulates and manufactures in-house, Stahlin Non-Metallic Enclosures (Belding, Mich.) produces composite boxes and enclosures for electrical systems and components.

Read MoreCorvette's carbon hood creates shock and awe

North America’s first mass-produced, all-CFRP hood raises the bar for production sports cars.

Read MoreIn-mold alternatives to postmold decoration

CT reviews viable, versatile technologies that reduce the time and cost of finishing composite parts.

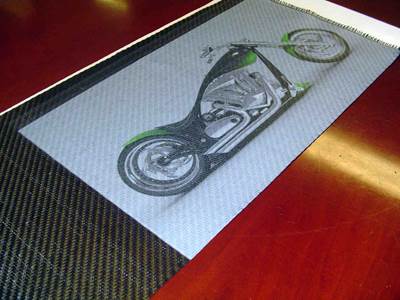

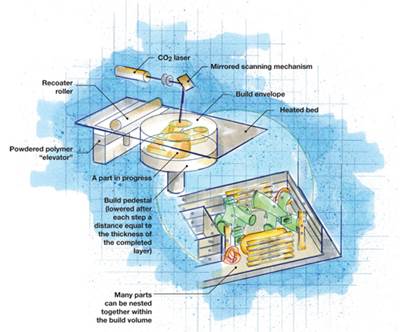

Read MoreThe rise of rapid manufacturing

An outgrowth of rapid prototyping, tool-free additive fabrication technologies have the potential to form small, limited-run composite parts directly from CAD data.

Read MoreComposite engine valves?

HPC technical editor Sara Black reports progress on CFRP intake and exhaust valves for race car engines.

Read MoreAutomating wind blade manufacture

Recent technology announcements portend a new era of more efficient blade production.

Read MoreTeam-built bus body bests all

OEM meets tight development schedule on superlight multipart molded shell to offset propulsion system weight in fuel cell-powered transit bus.

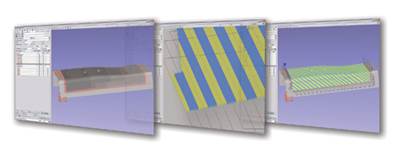

Read MoreAFP/ATL design-to-manufacture: Bridging the gap

Managing production of a structure made via fiber or tape placement often requires software-aided manipulation of the subtle differences between that which is designed and that which can be manufactured.

Read More