Processes

New packaging machine uses lightweight carbon fiber airshafts

When Premier Paper Converting Machinery (New Berlin, Wis.) introduced its new custom machine for producing Kraft paper honeycomb used to make packaging materials, the device was equipped to hold four massive 98-inch/2.4m wide rolls of paper, each one weighing 5,300 lb/2,409 kg. To support these paper rolls during u

Read MoreComposites take the hit in U.S. Navy patrol boat

New carbon/Kevlar composite hull and deck provide impact-absorbing solution to crew injury problems caused by severe vertical acceleration of previous high-speed, all-metal patrol boat.

Read MoreATL and AFP: Signs of evolution in machine process control

Improved machine-control software, placement accuracy and design simulation have made automated fiber placement and tape laying machines truly production-worthy. The evolution, however, still continues.

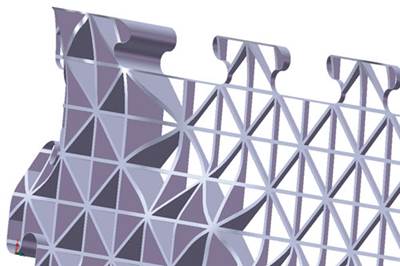

Read MoreRapid Manufacturing, Part II: Pioneer Applications

Harbingers of what could be a significant trend, these composites manufacturers demonstrate the potential of additive fabrication and several innovative materials in tool-free manufacture of complex components.

Read MoreRapid Manufacturing, Part I: The Technologies

An outgrowth of rapid prototyping, tool-free additive fabrication is shortening product development cycles for manufacturers of smaller, limited-run composite parts.

Read MoreTaking Subjectivity out of Class A Surface Evaluation

Toward the goal of more consistent, repeatable and quantifiable Class A surface analysis, automakers and systems suppliers are developing and employing automated surface inspection tools.

Read MoreThere are no bad ideas

Whenever we, as an editorial staff, sit down to begin planning editorial features and other articles for the coming year, we get our ideas from a variety of sources.

Read MoreATL and AFP: Defining the megatrends in composite aerostructures

Automated tape laying and automated fiber placement technologies take a key enabling role in production of today’s — and tomorrow’s — composite-airframed commercial jets.

WatchAutomating and optimizing autoclave cure

Software-based autoclave control system increases company’s cure throughput by 35 percent and frees engineers for more productive work.

Read MoreComposites Protect Pipe in Downhole Environment

Glass-reinforced epoxy provides a durable and affordable liner for alternative pipe used in enhanced oil recovery.

Read More