Processes

Machining carbon composites: Risky business

As composites take a larger part (and form larger parts) in the aerospace structures sector, it’s not just a make-it-or-break-it proposition.

Read MoreStructural polyurethanes: Bearing bigger loads

The versatile polymer shows new strength (and other advantages) in pultrusion and core materials applications.

Read MoreAdditive manufacturing a new frontier for composites

Leading additive manufacturing authority Terry Wohlers (Wohlers Associates Inc., Ft. Collins., Colo.) comments on two decades of AM progress and AM's prospects as a composites manufacturing solution.

Read MoreA400M cargo door: Out of the autoclave

This structural military airframe part is the largest made to date via the vacuum-assisted resin infusion process.

Read MoreVery Light Jets Creating A Demand For Composites

"Baby" jets are causing an aviation buzz but will the market exist?

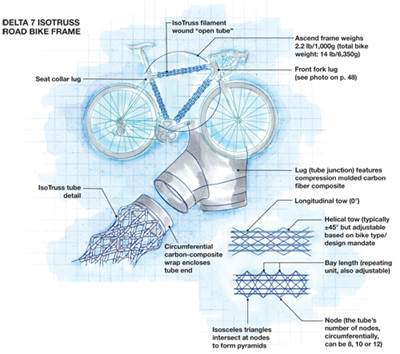

Read MoreNew twist in cycling: A truss bikers can trust

An "open tube" alternative to the solid-tube bike frame.

Read MoreDDG-1000 Zumwalt: Stealth warship

U.S. Navy navigates radar transparency, cost and weight challenges with composite superstructure design.

Read MoreNew infusion regime for superthick laminates

Innovative initiator chemistry yields long flow time, cure on demand and exotherm control for large, thick parts.

Read MoreUBSs: Coming to North America

Common in Europe and Asia, the composite underbody shield might finally catch on in the U.S. and Canada.

Read MoreRTM showcase: One-Piece Rudder

A transatlantic design team uses concurrent engineering to integrate rudder spars, ribs and skins in a single RTM cycle.

Read More