Processes

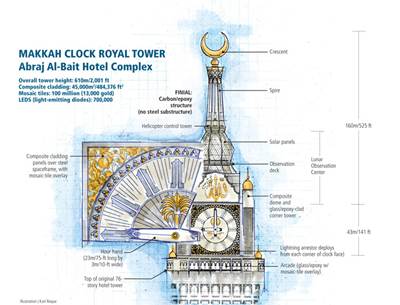

Besting Big Ben: A Marvel in Makkah

Composite design makes possible the world’s largest clock and tallest clock tower.

Read MoreCorrosion resistance: Desert-bound chemical and potable-water tanks

RL Industries (Fairfield, Ohio) recently overcame logistical obstacles to successfully fabricate five large composite storage tanks for a chemical plant in Saudi Arabia.

Read MoreSQRTM enables net-shape parts

New out-of-autoclave process combines resin transfer molding with prepregs for complex helicopter part prototype.

Read MoreStructural armor or armored structures?

Either way, antiballistics engineers seek structural integrity and ballistic deterrence from a single design.

Read MoreBuilding on CCM lessons learned

Knowledge gained during NASA's composite crew module (CCM) program, a sidelight to the Orion space capsule program, now benefits private space efforts.

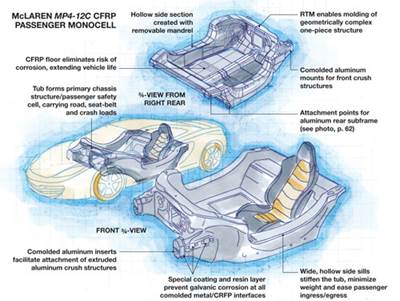

Read MoreF1-inspired MonoCell: Racing safety for the road

Resin transfer molding makes CFRP passenger cell mass-producible for new model supercar.

Read MoreDeepsea submersible incorporates composite pressure capsule

Spencer Composites Corp. (Sacramento, Calif.) fabricates the inner carbon/epoxy composite pressure capsule for a submersible deepsea vessel the late Steve Fossett was to take to the depths of the Pacific Ocean's Mariana Trench.

Read MoreLightweighting a heavyweight

Process combination produces significantly lighter overhead storage bins for big-rig sleeper cabs.

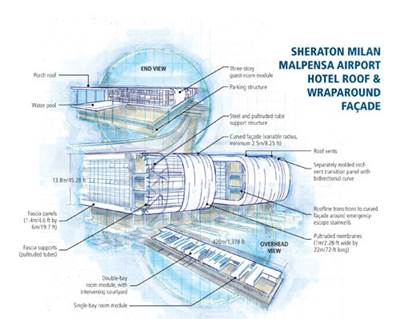

Read MoreHotel wrap: Curvilinear pultrusions

Airport hotel’s striking wraparound roofline made possible, durable and affordable with pultruded flat panels and profiled support structures.

Read MoreThermoformable thermoplastic composites

Thermoplastic composites that can be shaped into finished parts via thermoforming are proliferating as the thermoforming process gains traction, particularly in aerospace manufacturing. The following short article and chart provide some guidance in terms of sourcing.

Read More