Processes

CNC routers optimize cooling tower build

Although cooling towers traditionally have been made with wood and concrete, composite materials are gaining acceptance due to their corrosion and rot resistance, light weight and ease of installation.

Read MoreMining the potential of polyurethane composites

Pultruded rollers for mine conveyors outperform steel and portend a huge new market.

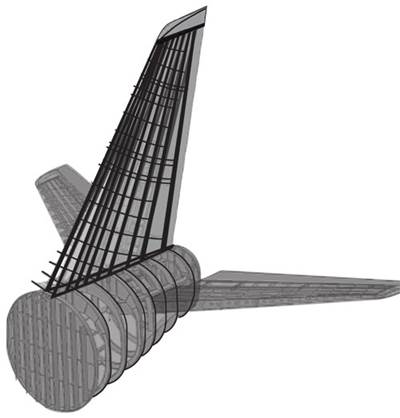

Read MoreCost- and time-saving preform process used for propeller spinner

Carbon fiber/epoxy spinner uses pulp slurry preforming process combined with vacuum infusion molding.

Read MoreInside R and D: A-VaRTM takes flight in Japan

Tests show out-of-autoclave process can reduce costs on new regional jet.

Read MorePultruding cost out of aerospace parts

Design-for-manufacturing effort proves to be cost-effective for carbon/epoxy airfoil on expendable UAV.

Read MoreDielectric heating speeds honeycomb core manufacture

Many composites, particularly those made with glass or aramid fibers in a polymer matrix, tend to be inherently nonconductive.

Read More"Metalworking" businesses find new niche with composites

Composite structures are replacing machined metal parts in certain applications — most notably, some aircraft components. As this happens, it would be easy to assume that businesses invested in machining metal will see activity decline. From the ground, however, there is plenty of evidence to support a different assumption.

Read MoreHigh-Volume Preforming for Automotive Application

More than a dozen parts for four Aston Martin models are mass produced in France using Ford Motor Co.'s optimized Programmable Preforming Process and resin transfer molding.

Read MoreComposites and Polymer Concrete Refine Mining Processes for Nonferrous Metal

Cost-effective alternatives to steel-reinforced concrete offer corrosion-resistant acid tanks to electrolytic refinery operations.

Read MoreNew Bridge Deck Bests Early FRP Systems

Mechanically fastened, two-piece composite deck system addresses challenges inherent in previous fiber-reinforced polymer deck designs, lowering cost, speeding installation and reducing maintenance.

Read More