Reinforcements

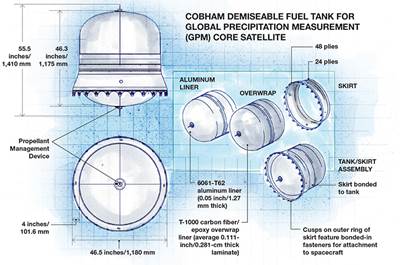

Space mission maximized via minimized survivability

CFRP design and manufacturing flexibility prove key in first spacecraft fuel tank designed to disintegrate upon reentry for improved mission efficiency and debris mitigation.

Read MoreMarket Outlook: Surplus in carbon fiber's future?

Participants at CW’s Carbon Fiber 2012 Conference see one coming as early as 2016.

Read MoreFaster cycle, better surface: Out of the autoclave

GM is first automaker to use Class A CFRP parts from new pressure-press technology.

Read MoreMarket Outlook: Fiber-reinforced phenolics

When it comes to corrosion resistance and low smoke toxicity, it's hard to beat fiber-reinforced phenolics. Manufacturers look for new applications for this often overlooked material.

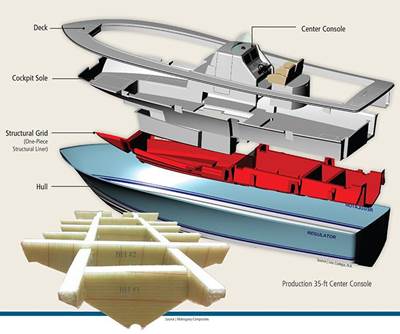

Read MoreThe structural grid: Prefabrication

Digitally designed and cut, preformed and preinfused stringers and bulkheads reduce boat weight, labor and cycle time and improve boatbuilder process control.

Read MoreDeep draw: Unique laminate architecture enables bus part

For a major mass-transit manufacturer, Amtech LLC (Wapato, Wash.) successfully thermoforms a luggage cover with a remarkably deep draw of 40 inches (1,016 mm), using a laminate architecture that includes a top layer of 0.180-inch/4.5-mm gauge Grade 4800 thermoplastic sheet, supplied by Boltaron (Newcomerstown, Ohio).

Read MoreIn new Corvette Stingray, another step forward for composites

Plasan Carbon Composites puts its "pressure press" process, developed with Globe Machine, to work in the manufacture of the hood and roof for the new 2014 Corvette Stingray, introduced last week at the Detroit Auto Show.

Read MoreTenCate's acquisition of Amber Composites a sensible surprise

TenCate, known for years as a thermoplastics specialist, is signaling more and more that it wants to move into new markets with new materials.

Read MoreAn impec-able bike frame: Handmade by machine

Long on technology firsts, this optimized, automated manufacturing process produces nothing short of the “perfect” bike frame.

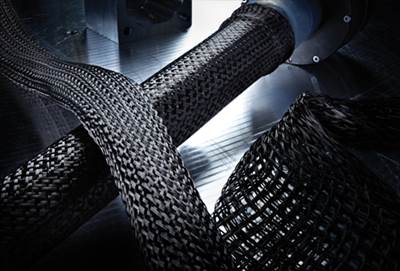

Read MoreNext-generation braiding for next-gen bike

When Grenchen, Switzerland-based Bicycle Manufacturing Co. (BMC) decided to braid the tubes for its impec racing bike frame, the use of carbon fiber and the complex tube designs and shapes prompted the use of radial braiding technology from August Herzog Maschinenfabrik GmbH & Co. KG (Oldenburg, Germany)

Read More