Reinforcements

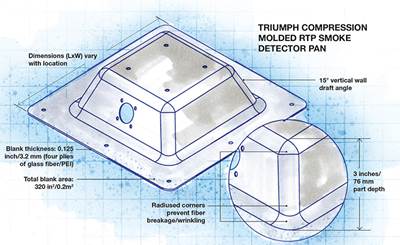

Compression molding mass out of aircraft interiors

Continuous carbon fiber-reinforced thermoplastic lightweights smoke detector pan and slashes production cycle time.

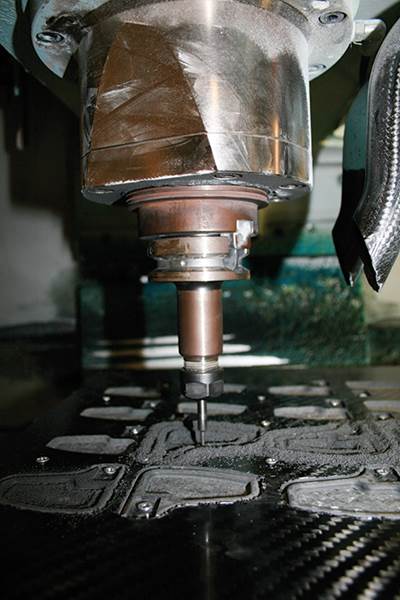

Read MoreSoftware supplier aids parts producer with greater accuracy

Paul Crosby (Crosby Composites, Brackley, Northamptonshire, U.K.) says PowerMILL software, which converts CAD models to NC toolpaths for multiaxis milling, has helped produce F1 composite parts to levels of accuracy rarely seen in the industry.

Read MoreToray + Zoltek = potential game changer?

Consultant Dale Brosius, also president of Dayton, Ohio-based Quickstep Composites LLC, the U.S. subsidiary of Australia-based Quickstep Technologies (Bankstown Airport, New South Wales), sees the Toray buyout of Zoltek as a potential auto-industry game changer.

Read MoreToray makes waves with Zoltek purchase

Toray was already the largest carbon fiber maker in the world, and with Zoltek it not only gets bigger, but expands into new markets.

Read MoreStructural preform technologies emerge from the shadows

Not yet in full production, with one exception, all are aimed at accelerating composite part manufacture at fast automotive rates.

Read MoreWind blades: Progress and challenges

Despite double-digit wind energy industry growth, turbine blade manufacturers and materials suppliers acknowledge a pressing need to reduce costs and innovate.

Read MoreManhole covers: Composites replace cast iron on university campus

Traditional cast-iron manhole covers are replaced on a college campus with composite versions manufactured by Fibrelite Composites (Skipton, North Yorkshire, U.K., and Pawcatuck, Conn.).

Read MoreHPC goes to SPE ACCE

CT Editor-in-chief Jeff Sloan fields initial reports from two CT staffers about the recent — and growing — Society of Plastics Engineers' Automotive Composites Conference and Exhibition.

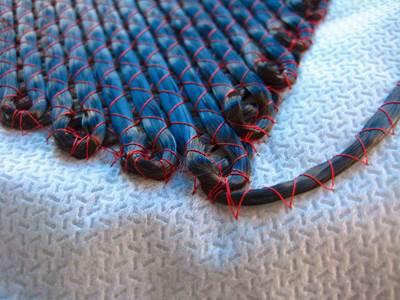

Read MoreTailored Fiber Placement: Besting metal in volume production

Affordable automated production of highly optimized preforms and parts.

Read MoreCarbon fiber composites: Into the automotive mainstream?

Altair Engineering Inc.'s (Troy, Mich.) VP of aerospace solutions Robert Yancey asks if automakers will follow aeromanufacturers in embracing carbon fiber.

Read More