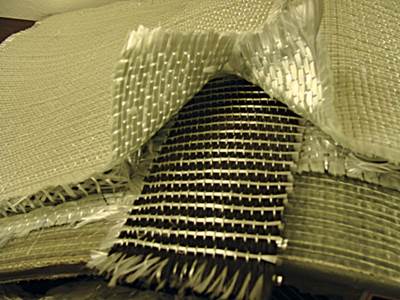

Reinforcements

Restoring a museum masterpiece with composites

Carbon fiber/vinyl ester reinforcement extends the structural life of architectural and art-world landmark.

Read MoreWind Blade Manufacturing: Cost-efficient materials-based strategies

The wind blade’s four key elements — the root, the spar, the aerodynamic shell or fairing, and the surfacing system — have present unique manufacturing challenges that must be met with carefully selected composite material systems and molding strategies.

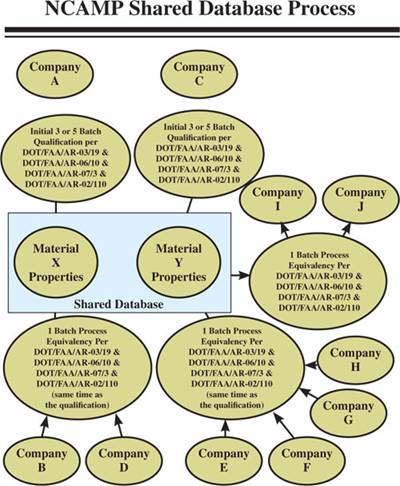

Read MoreShared composite material property databases

For more than a decade, NASA, FAA, industry and academia have been working toward the goal of creating a centralized composite material property database similar to that for metals. Their efforts, while productive, have not come with the war-like strength that the standardization of metals did. The composites industry is guided by Composite Materials Handbook 17 or CMH-17 (formerly known as MIL-HDBK-17).

Read MorePrepreg forecast: Strong growth through 2013

Prepreg applications are on the rise in the composites industry as manufacturers in a variety of industries increasingly adopt this versatile material. Today, prepregs find use in commercial aerospace, military/defense, general aviation, space/satellite, marine, sporting goods, automotive, civil engineering, wind

Read MorePolyurethane long fiber technology (LFT) replaces wood in spa surround

To many consumers, the thought of a relaxing soak in a hot tub is mighty appealing — but the thought of spa maintenance, particularly replacing rotted wood in the spa's cabinet-like enclosure, probably isn't. For spa manufacturer Clearwater Spas (Woodinville, Wash.), that reality and the fact that building decorativ

Read MoreNew metal coating to optimize composite tooling

Near the end of its development cycle, this nanostructured metal overlay promises to extend the working life and improve the cost-effectiveness of carbon/epoxy tooling.

Read MoreEngineering Insights: Glass/Thermoplastic Hood Steps Toward Commercialization

The hood design for Hyundai’s QarmaQ concept car is evaluated against European and Japanese pedestrian safety requirements.

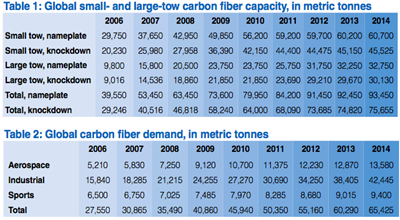

Read MoreCarbon Fiber 2007 looks forward with optimism

As high demand confronts a still limited supply, industry insiders and analysts meet to assess carbon fiber’s future and review emerging applications.

Read MoreMarket Trends: Carbon fiber demand, supply and the commodity threshold

CompositesWorld conferences director Scott Stephenson notes the increasing evidence at Carbon Fiber 2007 that the carbon fiber market is maturing.

Read More