Materials Testing

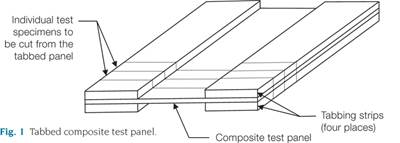

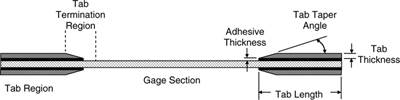

Tabbing composite test specimens: The how

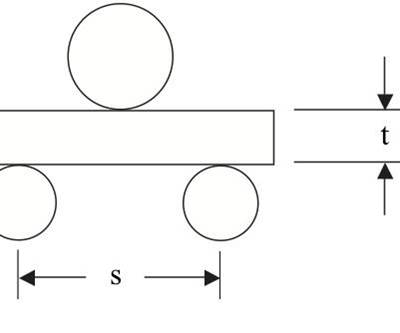

The when and why of tabbing composite test specimens were the subjects of my previous column (see “Tabbng composite test specimens: When and why," under "Editor's Picks," at right), which included a discussion of tabbing materials, tab thickness and taper angle, and adhesive selection.

Read MoreTabbing composite test specimens: When and why

Dr. Don Adams (Wyoming Test Fixtures Inc., Salt Lake City, Utah) discusses when and why test specimens must be protected by tabs.

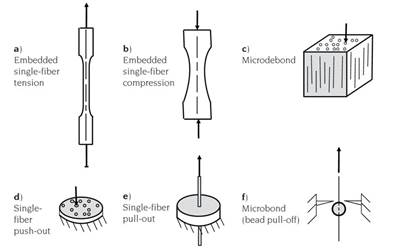

Read MoreFiber-matrix interfacial bond test methods

Dr. Don Adams describes six single-fiber methods for testing fiber-matrix interfacial bond strength.

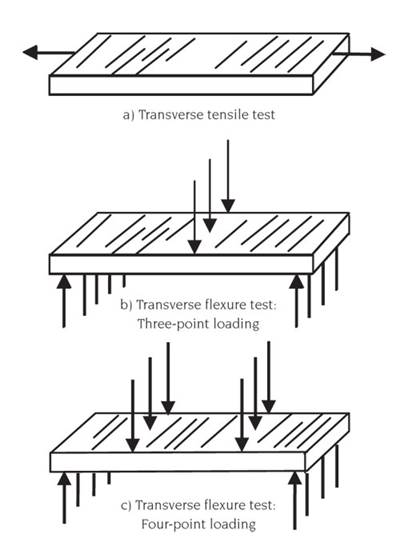

Read MoreTransverse flexure testing

Dr. Donald Adams examines test methods for determining the transverse tensile strength of a composite formed from unidirectional plies.

Read MoreThe short beam shear test

Dr. Don Adams (Wyoming Test Fixtures Inc., Salt Lake City, Utah) discusses short beam shear testing methodology.

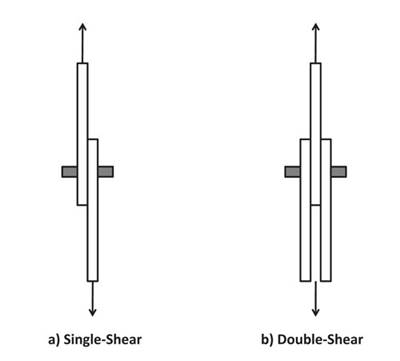

Read MoreFastener shear test methods

Dr. Donald Adams (Wyoming Test Fixtures, Salt Lake City, Utah) appraises existing methods for testing the performance of fasteners loaded in transverse shear.

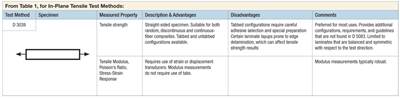

Read MoreGuide for Testing Polymer Matrix Composite Materials

Dr. Donald Adams offers insight into ASTM D 4762, a compendium of knowledge about standards relevant to testing polymer composites.

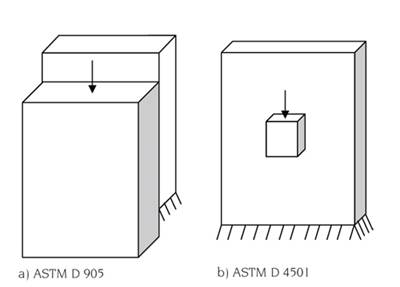

Read MoreBlock shear strength of adhesive bonds

Dr. Don Adams describes two methods (ASTM D 905 and ASTM D 4501) for loading adhesive bonds in direct shear while minimizing undesirable peel and through-thickness tensile stresses.

Read MoreUpsizing blade test regimes

As composite rotor blade size grows, research groups act to meet the urgent need for physical testing facilities with large-blade capacity.

Read MoreAdditional grip types for tensile test specimens

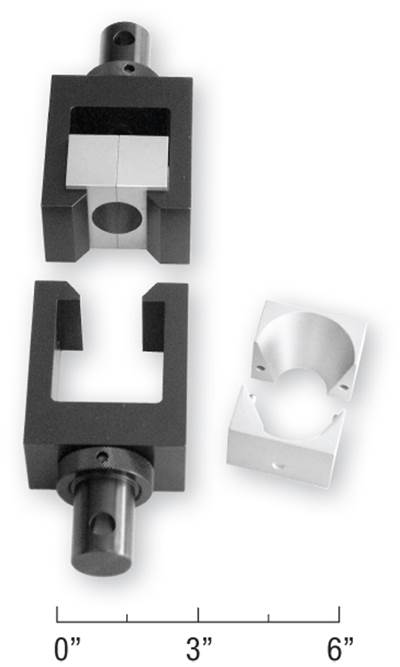

Dr. Don Adams follows up a previous discussion of wedge grips for testing tensile specimens with a sampling of other grip types.

Read More

.jpg;maxWidth=300;quality=90)