Weaving

Rediscovering the benefits of prepregs in composites manufacturing

Compared to more traditional forms of composites manufacturing, prepregs enable reduced manufacturing costs and enhance production performance.

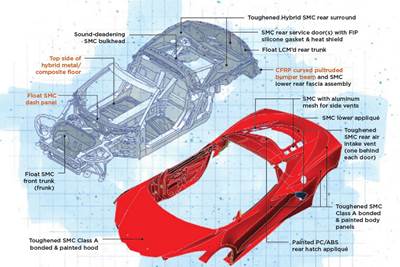

Read MoreComposites-intensive masterwork: 2020 Corvette, Part 2

Innovative composite materials trim mass, costs and noise on the high-volume mid-engine sports car.

Read MoreCAMX 2020 exhibit preview: DH Sutherland

DH Sutherland is introducing technologies for chemical application and the manufacture of protective armor.

Read MoreSustainable date palm fibers developed from agricultural waste

Developed by an Egyptian research consortium, PalmFil fibers and nonwovens have been developed for use in automotive composite applications and more.

Read MoreKordsa expands thermoplastic prepreg lineup

The new woven prepregs are offered with polypropylene or polyamide resin matrices in sheets up to 1.2 by 1.2 meters.

Read MoreEngineering Technology launches servo tensioner for filament winding

The ST2 system, tested with pitch carbon fiber and alumina fiber, enables high-speed wet, dry and towpreg winding.

Read MoreHigh-rate, automated aerospace RTM line delivers next-gen spoilers

At Spirit AeroSystem’s Prestwick facility in Scotland, a glimpse of the future of aerocomposites manufacturing in a resin transfer molding line for A320 spoilers.

Read MoreBio-based hybrid tapes assessed for lightweight applications

A project of AZL’s partner institute, ITA, integrates flax fiber reinforcement with a PA11 resin matrix. Targeted end markets include automotive and wind energy.

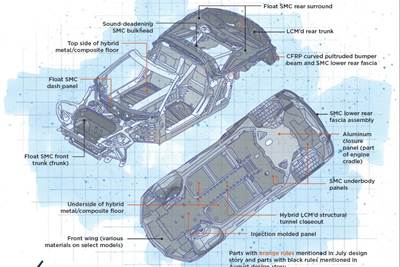

Read MoreComposites-intensive masterwork: 2020 Corvette, Part 1

Eighth-generation vehicle sports more composites, and features parts produced using unique materials and processes.

Read MoreThe untapped potential in Formula 1 composite manufacture

Formula 1’s midfield teams are struggling to bridge the gap to their better resourced frontrunning counterparts. Could Industry 4.0 composites manufacturing automation level the playing field?

Read More