SciGrip MMA to replace epoxy adhesive in wind blades

Methyl Methacrylate to offer up to 40 percent reduction in blade assembly cycle time plus address current maintenance issues due to variable bondline thickness.

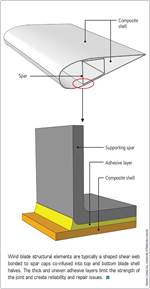

Wind blades currently use epoxy paste adhesive to bond top and bottom composite blade shells together around a prefabricated shear web, which also typically includes a bonded spar cap. The epoxy requires significant time to cure, and because the shell halves are mated blindly, without visual access to the bonding areas, the bondline thickness can vary wildly.

General Electric’s (Schenectady, N.Y., USA) patent US0027610, awarded in 2012, describes (underline added), “This configuration, however, often results in the use of excess bond paste to achieve the bond width . . . contributes unnecessary weight to the blade and can break off and result in blade “rattling” during operation . . . Also, air voids and unpredictable squeeze-out of the bond paste in the typical construction can result in areas of decreased bond strength, which is particularly problematic in sections of the blade where repair is not possible from within the blade. Accordingly, the industry would benefit from an improved bond configuration . . .”

SCIGRIP (Durham, N.C., USA) — one of the largest suppliers of methyl methacrylate (MMA) structural adhesives for composites and assembly adhesives used to bond dissimilar substrates, including composites, metals, and plastics — has a long history of technical development and working with customers to achieve productivity gains.

Sales and marketing director, Karen Brock Amoah, explains: “Our SG 747 structural adhesive has been evaluated to replace epoxy and other traditional adhesives at two large wind blade manufacturers, with qualification complete at one and nearing completion at the other. We have developed SG 747 with tensile strength and high temperature performance [up to 150˚F/66˚C] approaching that of epoxy, but with much better toughness at cold temperatures [down to -40˚F/-40˚C] — where epoxies become brittle — and an order of magnitude improvement in fatigue resistance, especially important for service in wind turbines.”

Amoah showed a thick wedge section bonded with SG 747 to demonstrate its thick-section capability at the far extreme. “No one would ever make a bondline this thick, but it shows that at 4.5 inches of adhesive thickness the SciGrip material provided good bond without any voids or boiling (due to exotherm).” Amoah notes that MMA chemistry is inherently moisture resistant and offers quick cure times without having to add heat, predicting a 40 percent reduction in production time for typical blade assembly operations.

Related Content

-

Henkel releases digital tool for end-to-end product transparency

Quick and comprehensive carbon footprint reporting for about 58,000 of Henkel’s adhesives, sealants and functional coatings has been certified by TÜV Rheinland.

-

BiDebA project supports bio-based adhesives development for composites

Five European project partners are to engineer novel bio-based adhesives, derived from renewable resources, to facilitate composites debonding, circularity in transportation markets.

-

Adhesives, material solutions promote end market versatility

CAMX 2023: Rudolph Bros. and Co. highlights its role as a prominent specialty chemical distributor and solutions provider with a display of high-performance adhesives, sealants, materials and more from well-known manufacturers.