CW Blog

If we recycle it, will they come?

Thanks to the 787 and the A350 XWB aircraft programs, the composites industry has more scrap carbon fiber prepreg than it knows what to do with. At least, not yet.

Read MoreComposites help Bell V-280 toward Future Vertical Lift

Bell’s design for future military helicopter uses hybrid metal-composite construction and Large Cell Carbon Core technology for unitized wing.

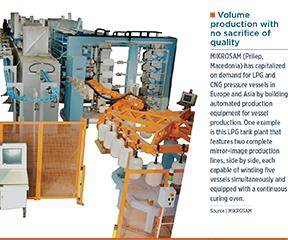

Read MoreAutomated filament winding enables competitive composite cylinders

Carefully controlled, robust, volume processes offer fabricators of Class IV LPG/CNG tanks a means to meet increasing demand in Europe and Asia.

Read MoreThermoplastic honeycomb cores: Tough insulated sandwiches

Foam-filled nylon/polyester fabric yields sandwich panel cores with excellent mechanicals, durability, thermal insulation.

Read MoreLow-density SMC: Better living through chemistry

Proprietary sizing, special glass roving and microspheres strip 9 kilos of weight from Corvette body panels.

Read MoreAircraft composites repair moves toward maturity

New technologies seek to address the challenges MROs will increasingly face in the age of commercial airliners with composite airframes.

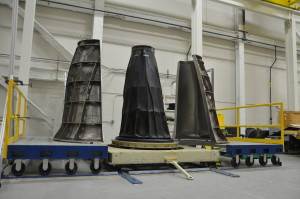

Read MoreGE Aviation, Batesville, MS, US

With a supply chain busy making commercial jet engines like the GE90, GEnx, LEAP and GE9X, GE Aviation has invested heavily in its composites capabilities in Batesville.

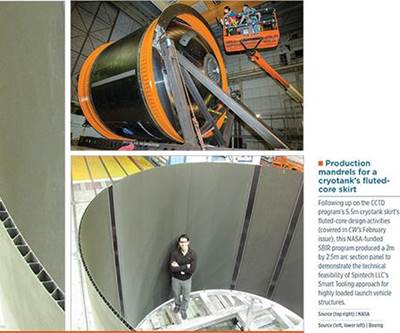

Read More“Smart tooling” cuts time and risk for complex unitized composite structures production

One-piece bladder tooling helps to actualize NASA/Boeing’s revolutionary fluted core design for next-gen cryogenic fuel tank skirt.

Read MoreFebruary supplement: Out-of-autoclave processing for aero use

We here at CW put together a supplement published with the February issue of the regular magazine that focuses on the technologies, tools and materials being used today in out-of-autoclave (OOA) processing for aerocomposites.

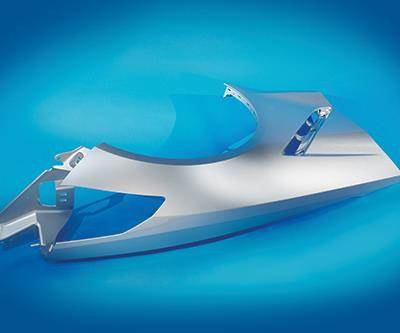

Read MoreInflexion technology: complex composites without fasteners

Spirit AeroSystems has developed production methods using rigid-flexible tooling for more affordable unitized composite aerostructures.

Read MoreBoat propellers with replaceable, interchangeable blades

Long glass fiber-reinforced polyamide makes this modular propeller tough enough for a challenging application, eliminating costly prop repair.

Read MoreAlternative precursor R&D: First commercial use of lignin carbon fiber?

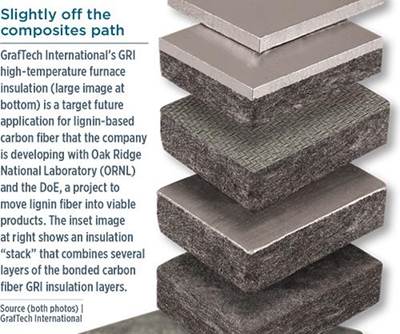

GrafTech International (Independence, OH, US) is working with Oak Ridge National Laboratory (Oak Ridge, TN, US) and the US Department of Energy’s Advanced Manufacturing Office to develop lignin fiber manufacturing and demonstrate it in viable products.

Read More