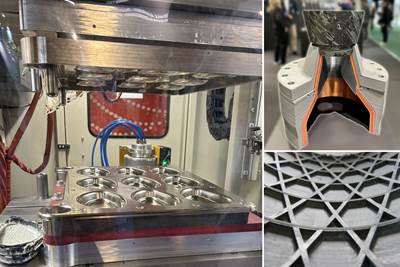

Optimizing robotic winding of composite tanks and pipes

Pioneer in mandrel-based reinforced rubber and composite products, TANIQ offers TaniqWindPro software and robotic winding expertise for composite pressure vessels and more.

WatchJEC World 2024 highlights: Thermoplastic composites, CMC and novel processes

CW senior technical editor Ginger Gardiner discusses some of the developments and demonstrators shown at the industry’s largest composites exhibition and conference.

WatchComposites end markets: Pressure vessels (2024)

The market for pressure vessels used to store zero-emission fuels is rapidly growing, with ongoing developments and commercialization of Type 3, 4 and 5 tanks.

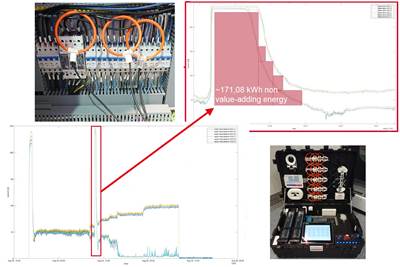

WatchMeasuring energy use to enable sustainable composites production

Airbus subsidiary CTC uses new technology to measure energy use in machine components and processes to optimize equipment, production lines and guide decisions for future composites.

Read MoreFraunhofer IWS completes MFFD longitudinal fuselage joint using CONTIjoin technology

Thermoplastic composite upper and lower half shells for the Multifunctional Fuselage Demonstrator were welded using CO2 laser over a total length of 8 meters.

Read MorePlant tour: Sekisui Aerospace, Orange City, Iowa, Renton and Sumner, Wash., U.S.

Veteran composites sites use kaizen and innovation culture to expand thermoplastic serial production, 4.0 digitization and new technology for diversified new markets.

WatchThe future of quartz and oxide fibers at Saint-Gobain Advanced Ceramic Composites

New business builds on 100-year legacy in quartz, prepares for growth, while starting production of oxide fibers to meet increased demand for CMC by aerospace and industrial sectors.

Read MoreMitsui Chemical, Microwave Chemical complete microwave-based carbon fiber demo facility

Completed in December 2023, the pilot production line at Mitsui Chemicals Nagoya Works began trials in January and will supply carbon fiber samples within fiscal 2024.

Read MorePlastic Omnium starts construction of Chinese mega-plant for H2 pressure vessels

The new PO-Rein joint venture factory in Jiading, Shanghai, aims to be operational in 2026, producing up to 60,000 hydrogen vessels and high-pressure hydrogen storage systems per year for the Chinese commercial vehicle market.

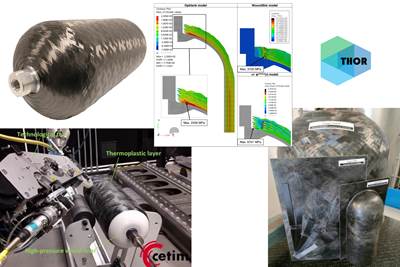

WatchUpdate: THOR project for industrialized, recyclable thermoplastic composite tanks for hydrogen storage

A look into the tape/liner materials, LATW/recycling processes, design software and new equipment toward commercialization of Type 4.5 tanks.

Read MoreHexagon Purus announces contract with New Flyer, results for Q4 2023

Supply of Type 4 composite H2 storage tanks for North American bus market extended, 2023 revenue up 37% due to H2 infrastructure solutions, heavy-duty truck, bus and aerospace, with 50% revenue increase expected in 2024.

Read MoreInfinite Composites awarded $470K contract to develop larger, higher pressure H2 tanks

Manufacturing Type V composite pressure vessels, Infinite Composites will match this project with a recently received $1.6 million award from the Army for conformable hydrogen tanks.

Read More