Composites end markets: Industrial (2024)

The use of composites in industrial applications is increasing, driven by the need for higher performance and longer life, whether its parts for industrial machinery, EOAT components, corrosion-resistant equipment and more.

Read MoreBio-based, fire-resistant composites become mainstream

Projects use Duplicor prepreg panels with highest Euroclass B fire performance without fire retardants for reduced weight, CO2 footprint in sustainable yet affordable roofs, high-rise façades and modular housing.

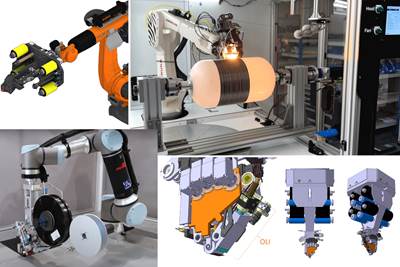

WatchThe next evolution in AFP

Automated fiber placement develops into more compact, flexible, modular and digitized systems with multi-material and process capabilities.

Read MoreHexagon Purus extends agreement for hydrogen distribution systems, raises 1 billion NOK

Agreement with green hydrogen producer extended for 2024, investment will support ongoing global capacity expansions including CFRP cylinder production.

Read MoreHexagon Agility receives order for Titan Mobile Pipeline, boosts production of composite cylinders

Order from REV LNG highlights growth in renewable natural gas; Hexagon Agility ramps Type 4 Mobile Pipeline cylinder production and adds two Type 4 cylinder lines in Salisbury, N.C. to meet demand for truck/bus systems.

Read MoreAirbus opens ZEDC in Stade for H2 systems using composites

Zero-emission development center in Germany will target cryogenic liquid hydrogen tanks using lightweight carbon fiber-reinforced composites for proposed aircraft to enter service by 2035.

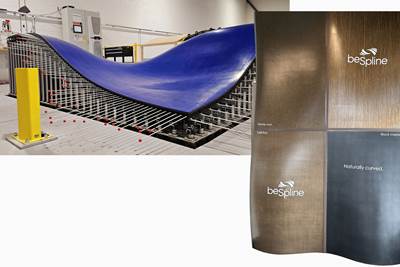

Read MorePlant tour: BeSpline/Addcomp, Sherbrooke, QC, Canada

Composites automation specialist increases access to next-gen technologies, including novel AFP systems and unique 3D parts using adaptive molds.

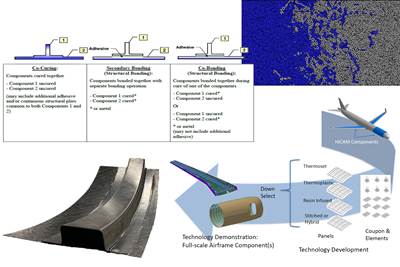

Read MoreThe potential for thermoplastic composite nacelles

Collins Aerospace draws on global team, decades of experience to demonstrate large, curved AFP and welded structures for the next generation of aircraft.

WatchWelding is not bonding

Discussion of the issues in our understanding of thermoplastic composite welded structures and certification of the latest materials and welding technologies for future airframes.

Read MoreCompositesWorld, ITHEC partner for 2024 event

Leading thermoplastic composites event prepares for seventh conference featuring latest developments, leading players and panel discussion on energy transition hosted by CW.

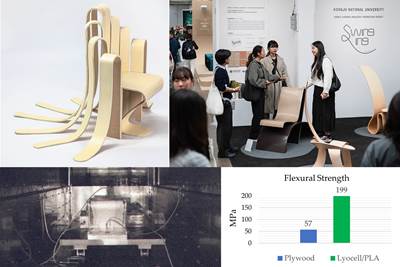

Read MoreKCARBON and KIST develop lyocell/PLA/wood biocomposites

Initial demonstration in furniture shows properties two to nine times higher than plywood, OOA molding for uniquely shaped components.

Read MoreBio-based SiC ceramics from wood polymer composites

Austrian research institute Wood K plus makes 95% silicon carbide ceramics more sustainable (>85% bio/recycled content), enables 3D shapes via extrusion, injection molding and 3D printing.

Read More