Ex-Core Technologies' Ex-Core 2.0 system features intelligent self-heated tooling, custom-mixed core

Debuted at JEC World 2022, Ex-Core 2.0 is said to slash production costs compared to conventional prepreg sandwich processes and produce lighter, stronger parts.

WatchAIR ONE two-seater eVTOL achieves first hover tests

AIR’s all-electric personal air mobility vehicle, which incorporates composites in structural and aesthetic components, is expected to deliver its first vehicles by 2024.

WatchOverair's Butterfly eVTOL prototype to integrate composites-intensive design

Aiming for first flight tests in the latter half of 2023, Overair’s Butterfly aircraft uses Toray carbon fiber/epoxy prepreg strategically to cut weight on its battery-powered, quiet aircraft.

WatchHigh-performance, high-detail continuous 3D-printed carbon fiber parts

Since 2014, Mantis Composites has built its customer and R&D capabilities specifically toward design, printing and postprocessing of highly engineered aerospace and defense parts.

Read MoreAluula introduces lightweight composite materials for wind sports and beyond

The company’s proprietary UHMWPE fabrics combined with technical films in a patented fusion process are said to increase performance and recyclability.

Read MoreData visibility increases efficiency, competitiveness for composite infrastructure solutions company

ClockSpring|NRI builds composite strengthening systems for pipes and civil structures, using Global Shop Solutions ERP software to help track and manage cost and production data.

Read MoreJEC World 2022, Part 2: Recycling, natural fibers and additive manufacturing

CW associate editor Hannah Mason recaps several technologies seen on display at JEC World 2022, including new developments from Bcomp, Massivit 3D, Gen 2 Carbon and more.

Read MoreDigital design, multi-material structures enable a quieter supersonic NASA X-plane

NASA’s composites-intensive X-59 QueSST experimental aircraft is set for its first flight by the end of 2022, after nine years of design, manufacture, assembly and testing by Lockheed Martin Skunk Works.

WatchMoving toward next-generation wind blade recycling

Suppliers, fabricators and OEMs across the composite wind blade supply chain ramp up existing technologies, develop better reclamation methods and design more recyclable wind blades.

Read MoreGraphene nanotubes enhance conductivity, performance of composite printing sleeves

Two customer projects demonstrate that small amounts of OCSiAl's TUBALL nanotubes can replace carbon black for fiberglass composite printing sleeves.

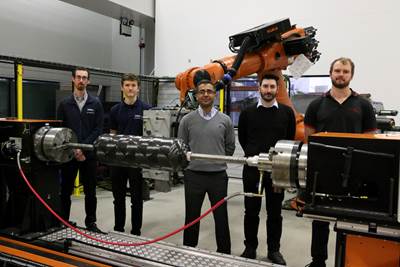

Read MoreAMRC, industrial partners develop Type IV hydrogen tank for long-haul vehicles

In the 12-month project, the University of Sheffield Advanced Manufacturing Research Centre (AMRC) has built prototype tanks and worked to build a secure U.K. supply chain.

Read MoreDesktop 3D printing companies MakerBot and Ultimaker agree to merger

The new entity will maintain headquarters in New York, U.S. and the Netherlands, with respective CEOs serving as co-CEOs.

Read More.jpg;maxWidth=250;quality=70)