Mito Material Solutions cuts ribbon on new facility in Indianapolis

The graphene additive developer, which serves sporting goods and other composites markets, grows its capabilities with a new facility that includes in-house R&D and testing space.

Read MoreFlexible, induction-based heating for thermoplastic composite part repair

Spinning off from a German Aerospace Center (DLR) research project, msquare GmbH’s technology aims to innovate and enable repair for high-temperature thermoplastics.

Read MorePlant tour: ÉireComposites, Galway, Ireland

An in-house testing business and R&D focus has led to innovative materials use and projects in a range of markets, from civil aerospace to renewable energy to marine.

WatchEvident wind blade inspection system automates nondestructive ultrasonic testing

An autonomous, cobot-mounted inspection system combines Industry 4.0 with established ultrasonic technology to rapidly provide repeatable, accurate data and improve overall efficiency.

WatchCarbon fiber composite hydrofoils to enable “world’s fastest” electric ferry

The Candela P-12 Shuttle, set to launch in Stockholm, Sweden, in 2023, will incorporate lightweight composites and automated manufacturing to combine speed, passenger comfort and energy efficiency.

Read MoreLockheed Martin expands development, production of ultra-high temp CMCs with facility expansion

Targeting current and future needs in hypersonic and aeronautics applications, Lockheed Martin Skunk Works’ Allcomp team is increasing and digitizing its capabilities in ceramic matrix composite (CMC) materials and parts fabrication.

Read MoreCAMX 2022 exhibit preview: UAMMI

The Utah Advanced Materials and Manufacturing Initiative (UAMMI) brings together academic and industry partners to promote composites industry growth in the state of Utah.

Read MoreDustless, mobile solution for on-site wind turbine blade repurposing

Denmark-based Isodan Engineering ApS translated its expertise in mobile, shipping container-based newspaper recycling systems to solve a need for breaking down wind turbine blades on-site for reuse.

Read MoreCollaborators awarded NIST funding to develop in-space manufacturing roadmap

Purdue, the University of New Hampshire and the University of Alabama will work with NASA to develop a roadmap for in-space manufacturing.

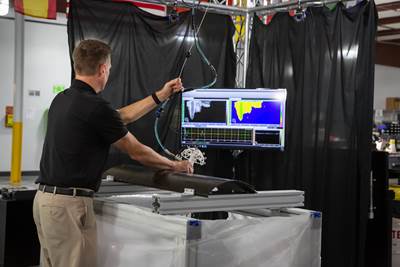

Read MoreCAMX 2022 exhibit preview: Innerspec Technologies

Taurus and Camus 3D ultrasonic inspection systems provide automated and semi-automated solutions for composite aerospace components.

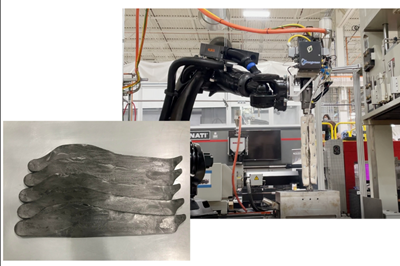

Read MoreLow-void, large-scale, high-volume 3D-printed composites

Among its many composites-related projects, Oak Ridge National Laboratory recently installed its first AMCM test cell, combining extrusion with compression molding for fast, low-void, low-porosity thermoplastic composite parts.

WatchVestas implements composites 3D printing to increase efficiency for blade alignment tools

A Markforged digital repository and multi-material 3D printers enable faster, more accurate and less costly manufacture of a variety of tools and blade components across Vestas sites.

Watch.jpg;maxWidth=250;quality=70)